Al-Mg-Si alloy wire for added material manufacturing and preparation method thereof

A technology of alloy wire and additive manufacturing, which is applied in the field of Al-Mg-Si alloy wire for additive manufacturing and its preparation, can solve the problems of high hot crack tendency, affecting the performance of high-strength aluminum alloy components, and low alloy strength, etc., to achieve Effect of improving mechanical and physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] A preparation method of Al-Mg-Si alloy wire rod for additive manufacturing, comprising the following steps:

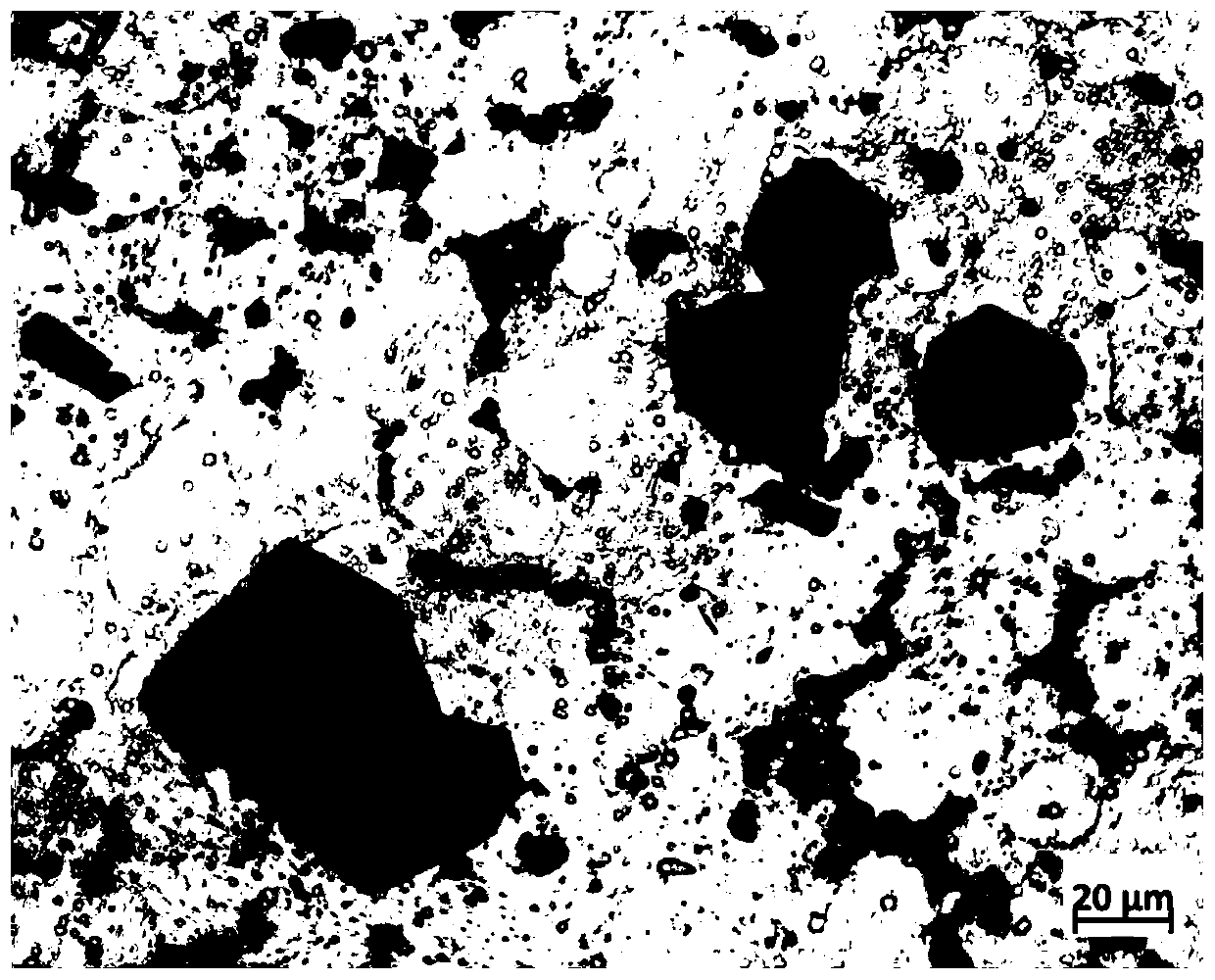

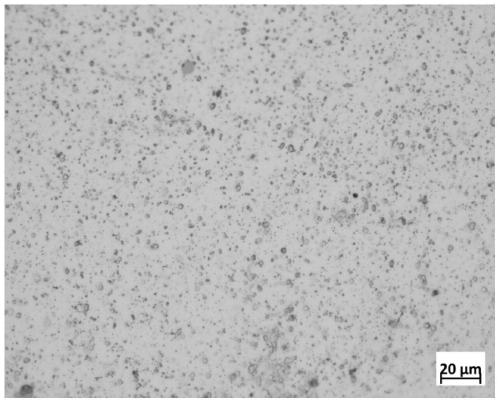

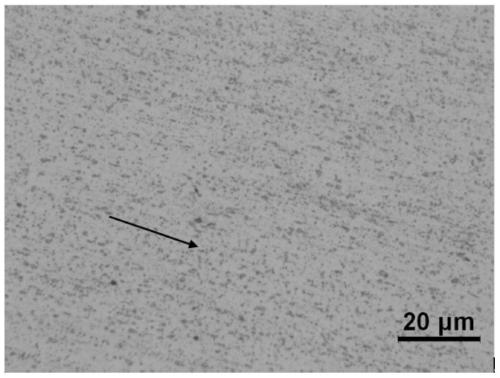

[0059] Step 1: Prepare 92.8Kg of TiB generated in situ 2 Granular Al-2.3Ti-B master alloy, in which TiB 2 The particle size is mostly 2-5μm, and after severe plastic deformation, it contains nano-TiB 2 Granular Al-2.3Ti-B master alloy, in which nano-TiB 2 The particle size is 50-1000nm.

[0060] Among them, severe plastic deformation can adopt high-speed friction stirring process or equal channel angular extrusion process or high-pressure torsion process. process, the torsion range is 0.5 to 5 turns; the equal channel angular extrusion process, the channel angle is 90 to 120 degrees, and the number of cycles is 1 to 5 times; the high-speed friction stir process is used in this embodiment.

[0061] Step 2: the nano-TiB obtained in step 1 2 The granular Al-2.3Ti-B master alloy is used as the matrix raw material, and 1.2Kg of pure magnesium, 5.0Kg of Al-20Si m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com