No. 0 block construction bracket and reverse tension preloading method thereof

A bracket and tension technology, applied in the field of 0# block construction bracket and its reverse tension preloading, can solve the problem of not being able to clearly determine the retraction amount of the anchor, the retraction amount of the steel strand, the subsidence amount of the bracket, and the process. It is difficult to control the grading pressure, and the difficulty of operation cannot be realized, so as to achieve the effect of expanding the scope of use, reducing the difficulty of construction, and reducing the cost of investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

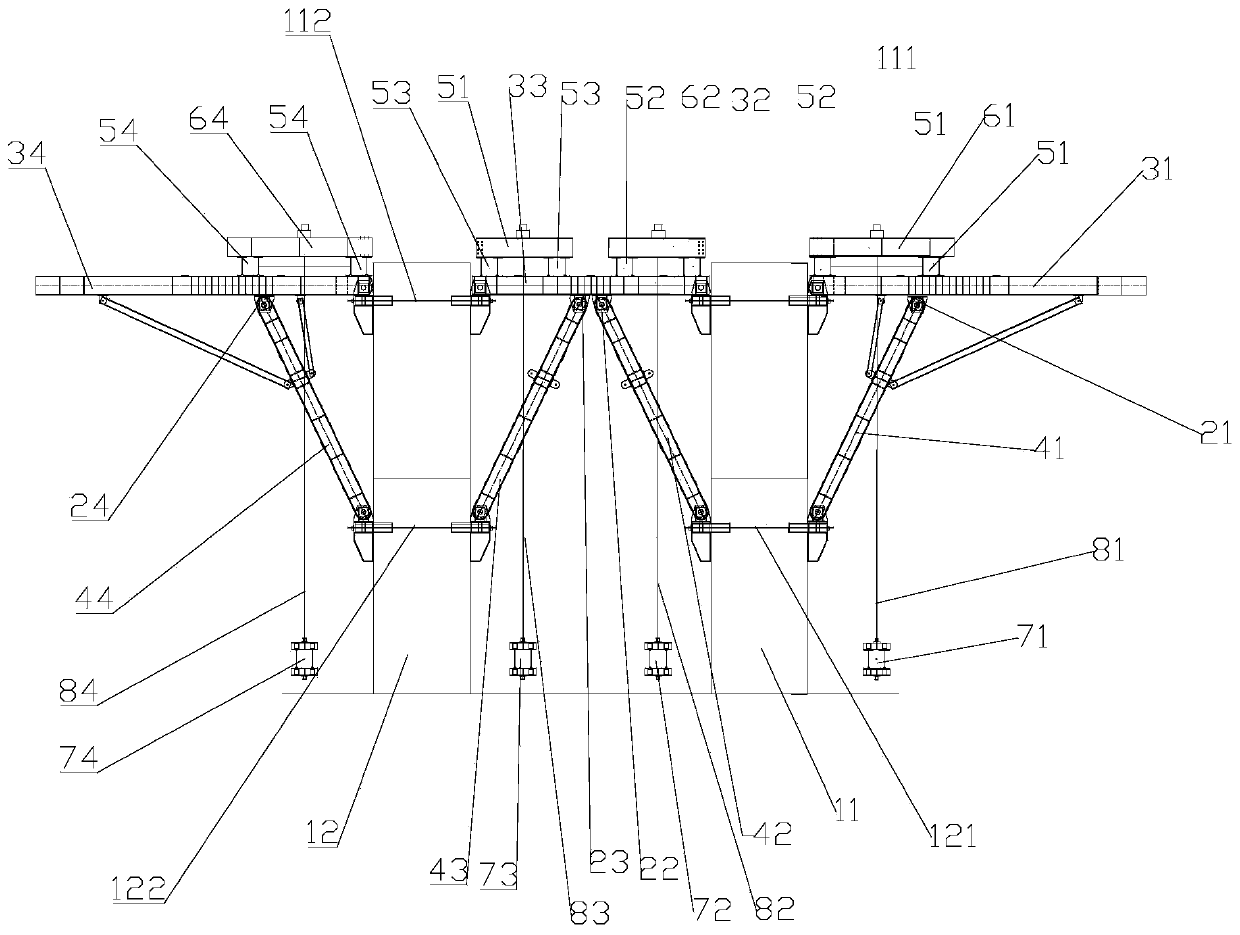

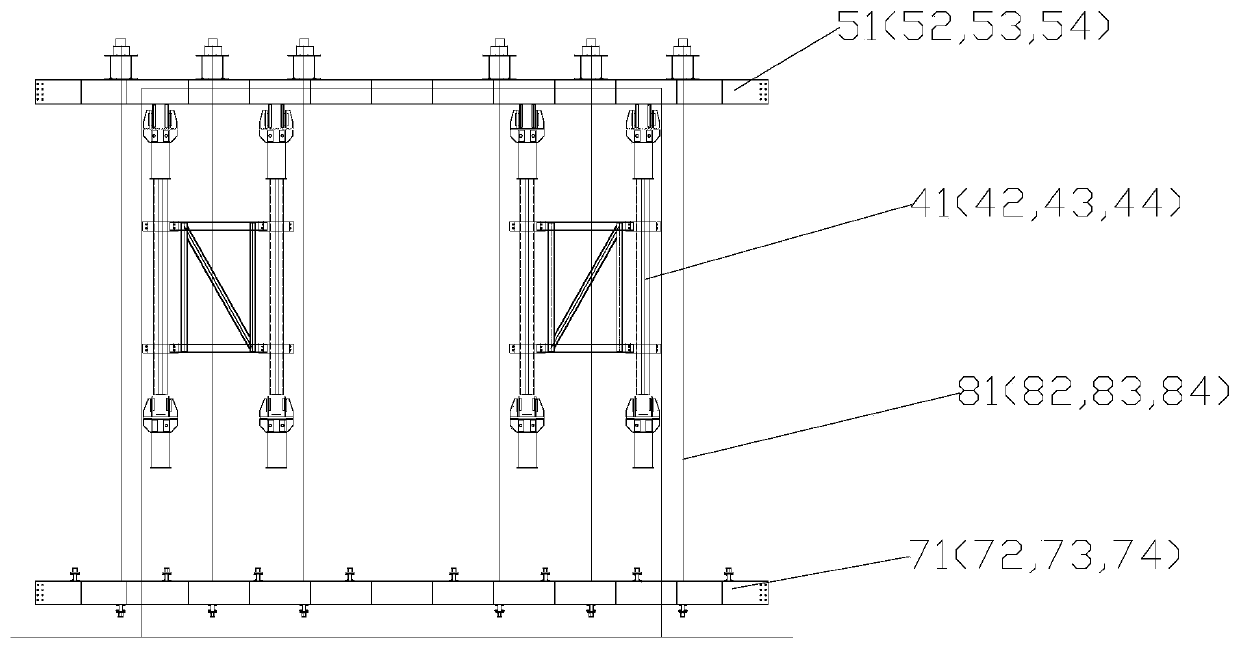

[0028] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1As shown in the figure, the 0# block construction bracket in this embodiment includes a bracket body, and the bracket body includes a bracket I21 and a bracket II22 symmetrically arranged on the outside of the two high piers, symmetrically arranged on the Bracket III23 and bracket IV24 inside the two high piers, the bracket I21 and the bracket III23 are relatively arranged on the high pier I11, and the bracket II22 and the bracket IV24 are relatively arranged on the high pier II12 , the high pier I11 is pre-embedded with an upper bracket I111 and a lower bracket I112 for installing the bracket I21 and the bracket III23, and the high pier II12 is pre-embedded with a bracket for installing the bracket The upper frame II121 and the lower frame II122 of the frame II22 and the bracket IV24, the bracket I21 includes a beam I31 mounted on the right end of the upper frame I111 at one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com