Construction method of section steel column concrete beam-column joint

A technology of beam-column joints and construction methods, which is applied in the directions of architecture and building structure, can solve the problems of complicated connection joints between steel-frame columns and concrete beams, inappropriate construction of steel bars at the bottom of beams, and difficulty in guaranteeing construction quality, etc. The effect of reducing the total construction progress, reducing the amount of engineering and labor input, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

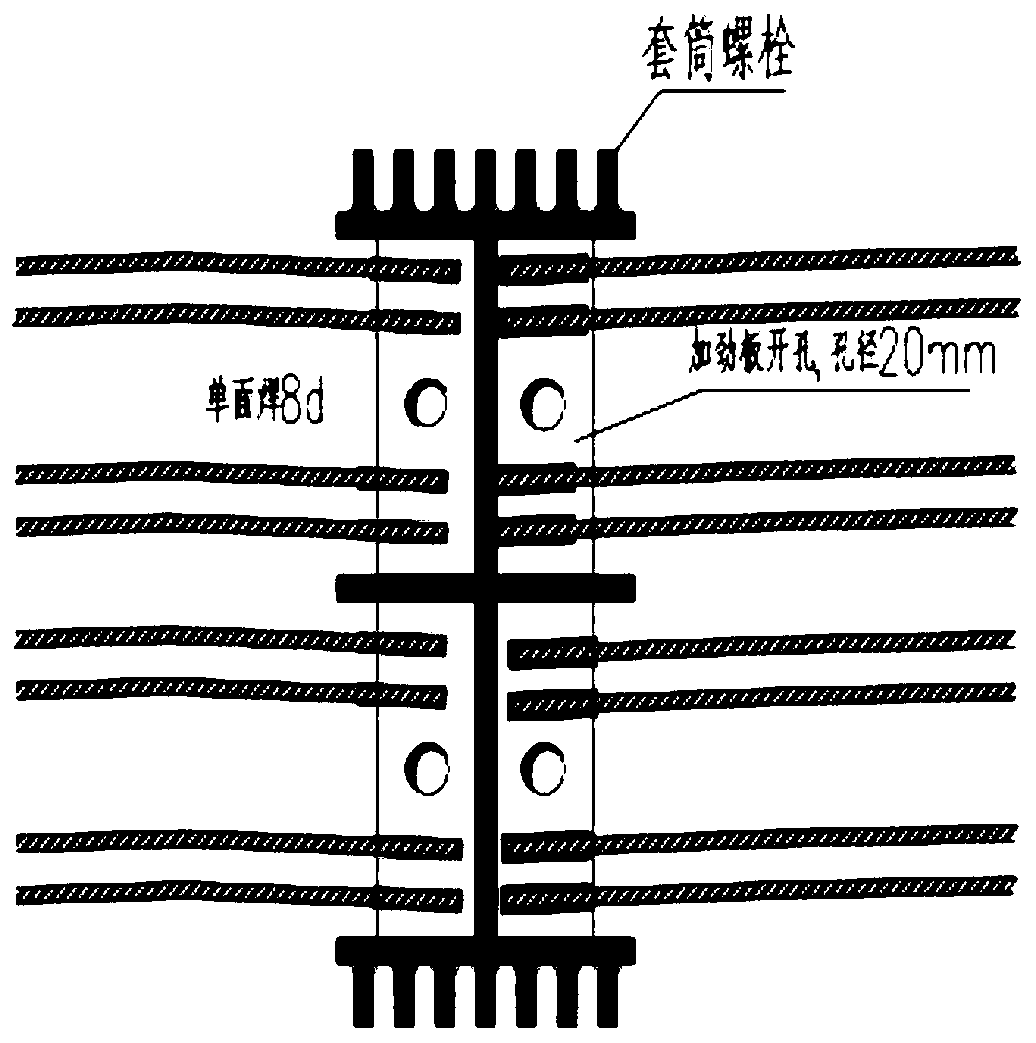

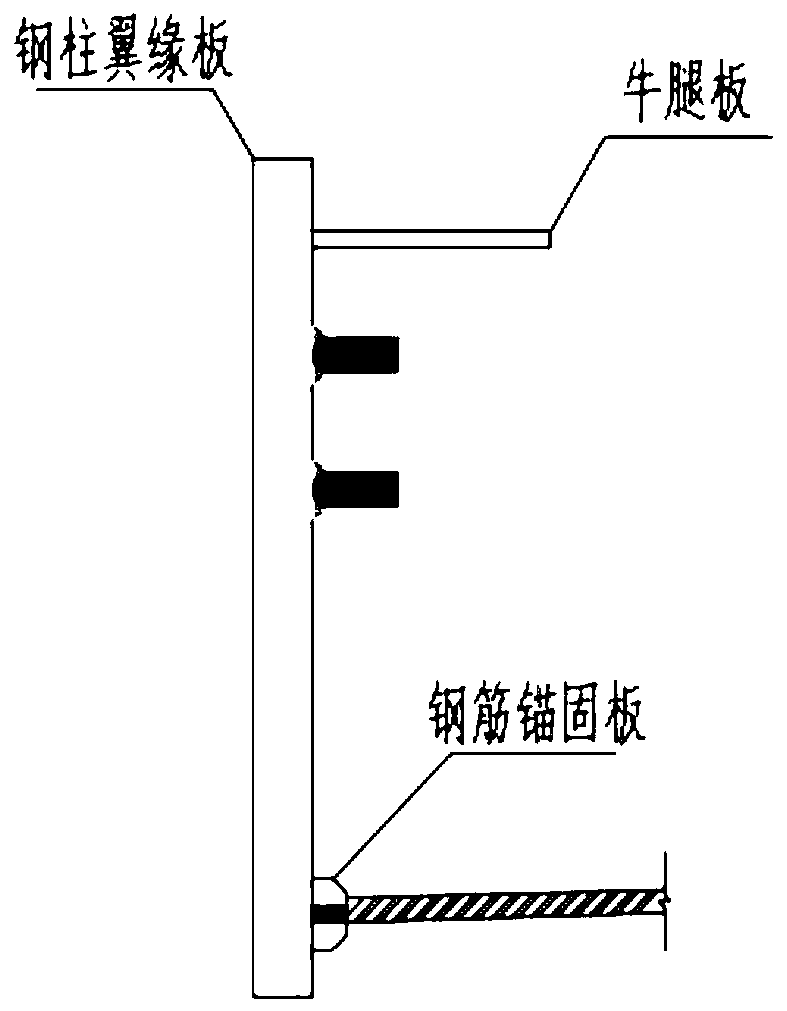

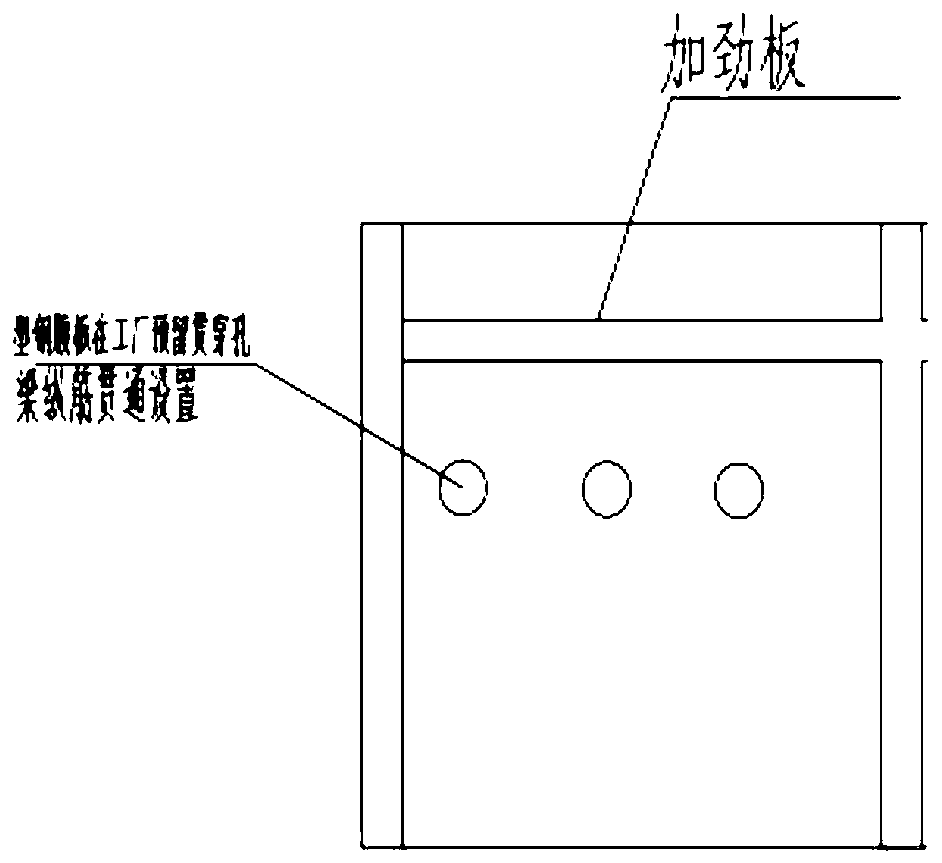

[0034] see Figure 1-5 , the present invention provides a technical solution: a construction method for steel column concrete beam-column joints, comprising the following steps:

[0035] S1: The section size of the shaped steel beam is kept consistent, the position of the gluten is kept through, the bottom reinforcement at the bottom of the gluten meets the flange and the web of the shaped steel, and when the anchorage length of the straight section is satisfied, use a bent anchor or a steel anchorage plate for anchoring;

[0036] S2: Review the design after deepening the drawings provided by the design, and start the construction work after the review is passed and the design is approved;

[0037] S3: When installing the steel frame of the column, first make temporary connections at the upper and lower steel frames, then observe and correct the vertical deviation, and then perform welding or high-strength bolt connection, and then after the steel frame of the beam is installe...

Embodiment 2

[0049] see Figure 1-5 , the present invention provides a technical solution: a construction method for steel-column concrete beam-column joints, comprising the following steps:

[0050] S1: The cross-sectional size of the shaped steel beam is kept consistent, the position of the gluten is kept through, and the bottom reinforcement at the bottom of the gluten meets the flange and web position of the shaped steel. When the anchorage length of the straight section is satisfied, use a bent anchor or a steel anchorage plate for anchoring;

[0051] S2: Review the design after deepening the drawings provided by the design, and start the construction work after the review is passed and the design is approved;

[0052]S3: When installing the steel frame of the column, first make temporary connections at the upper and lower steel frames, then observe and correct the vertical deviation, and then perform welding or high-strength bolt connection, and then after the steel frame of the beam...

Embodiment 3

[0064] see Figure 1-5 , the present invention provides a technical solution: a construction method for steel column concrete beam-column joints, comprising the following steps:

[0065] S1: The section size of the shaped steel beam is kept consistent, the position of the gluten is kept through, the bottom reinforcement at the bottom of the gluten meets the flange and the web of the shaped steel, and when the anchorage length of the straight section is satisfied, use a bent anchor or a steel anchorage plate for anchoring;

[0066] S2: Review the design after deepening the drawings provided by the design, and start the construction work after the review is passed and the design is approved;

[0067] S3: When installing the steel frame of the column, first make temporary connections at the upper and lower steel frames, then observe and correct the vertical deviation, and then perform welding or high-strength bolt connection, and then after the steel frame of the beam is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com