Flexible membrane material shearing performance testing method considering tensile-shear coupling effect

A test method and coupling effect technology, applied in the direction of using a stable shear force to test the strength of the material, can solve the problems of the significant influence of the shear mechanical properties of the membrane material and the error of the shear parameters, so as to improve the test accuracy and applicability properties, moderate specimen size, and accurate acquisition of material shear parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing.

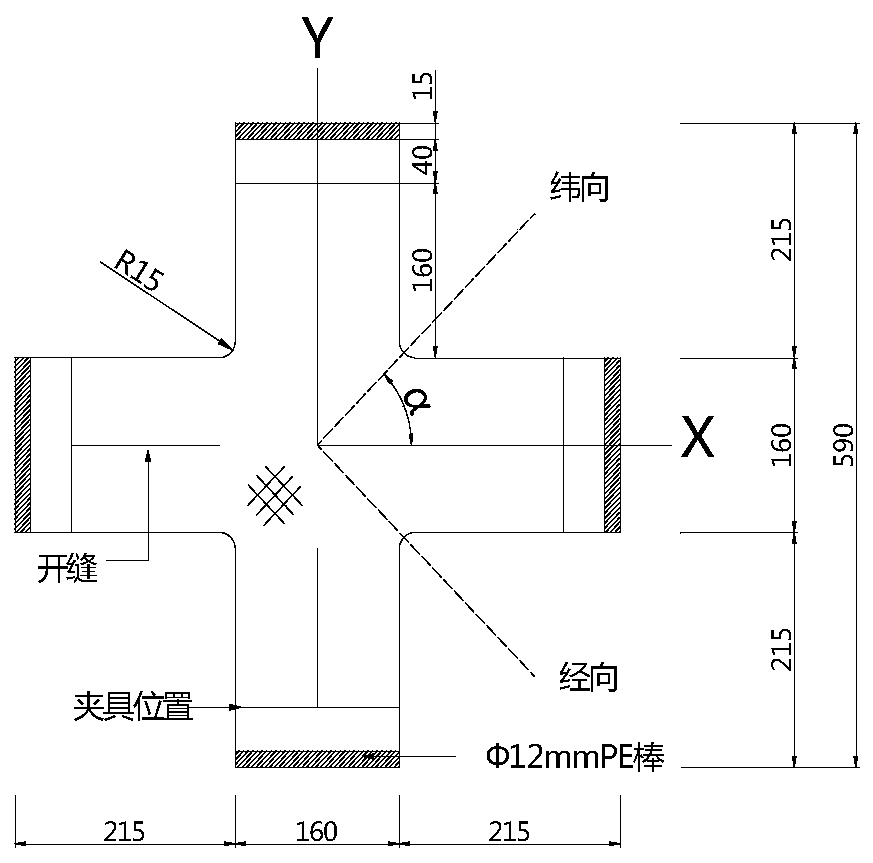

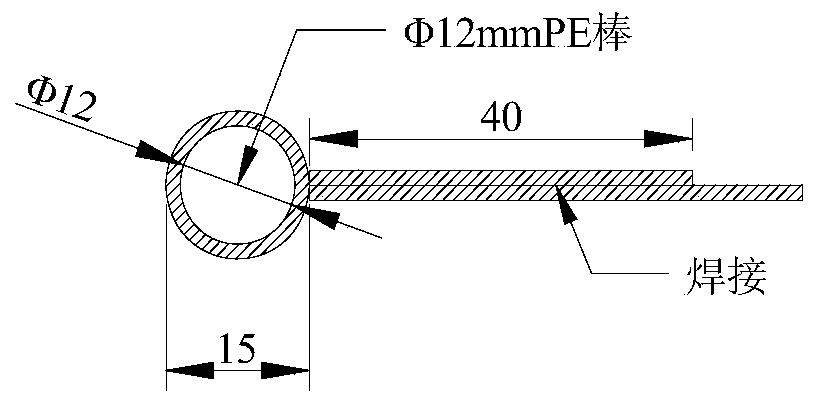

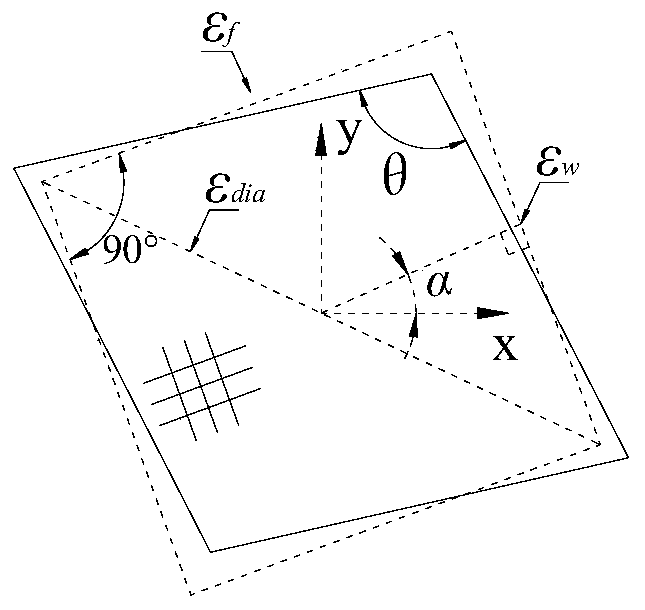

[0038] The present invention is a method for testing the shear mechanical properties and mechanical parameters of membrane materials, which can be applied to the determination of shear mechanical properties and shear mechanical parameters of membrane materials such as thermoplastic polymer films, coated fabric films and laminated fabric films, Obtain accurate and reliable shear mechanical properties and shear mechanical parameters. Follow the steps below to implement it:

[0039] The first step is to determine the tensile and shear stress state range of the membrane material test. According to the actual engineering case - the stress state of the membrane surface of the nose cone of the airship membrane structure, the numerical method ( Figure 5 ), determine that the range of tensile stress ratio N used for the test is [2 / 3,3 / 2], the range of tensile stress σ is [1kN / m,7k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com