Method for improving gel properties of fish myofibrillar protein

A myofibrillar protein and gel technology, which is applied in fish protein components, animal protein processing, protein food ingredients, etc. The glue performance is weak, and the texture and shape cannot be satisfied, so as to achieve good application prospects, easy industrial production and application, and reduce energy consumption and reagent consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

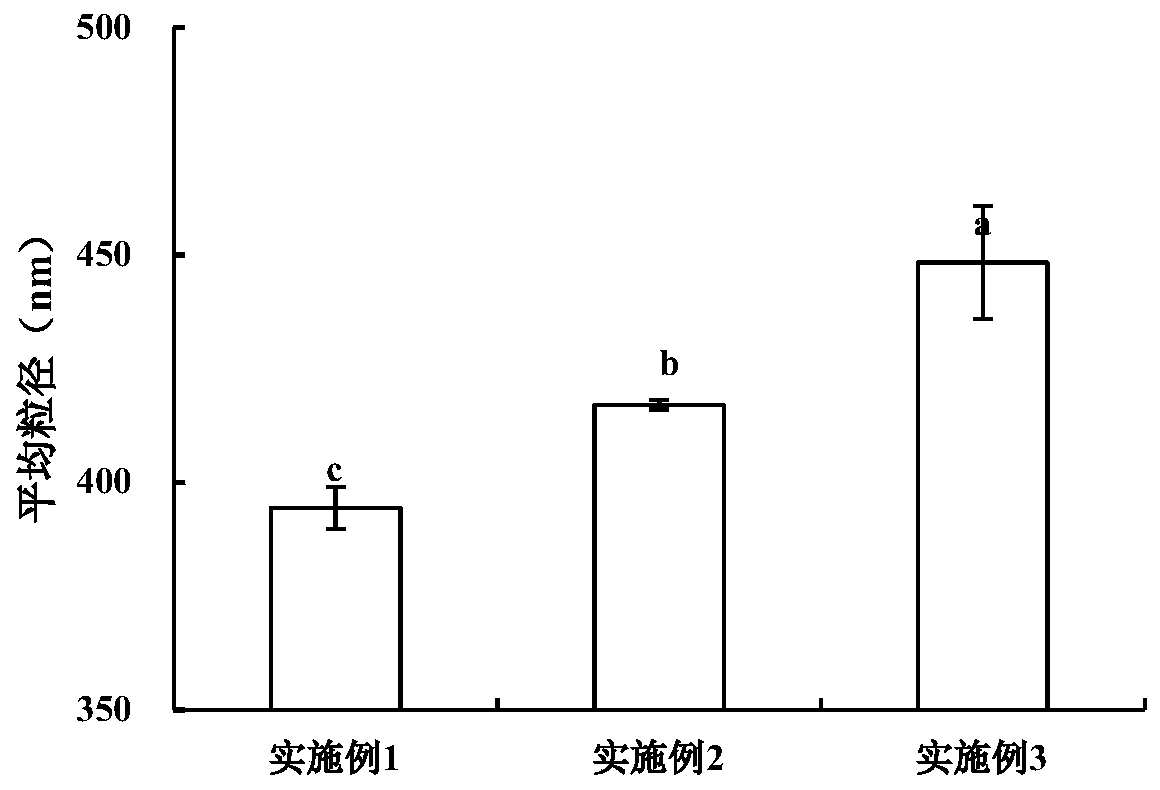

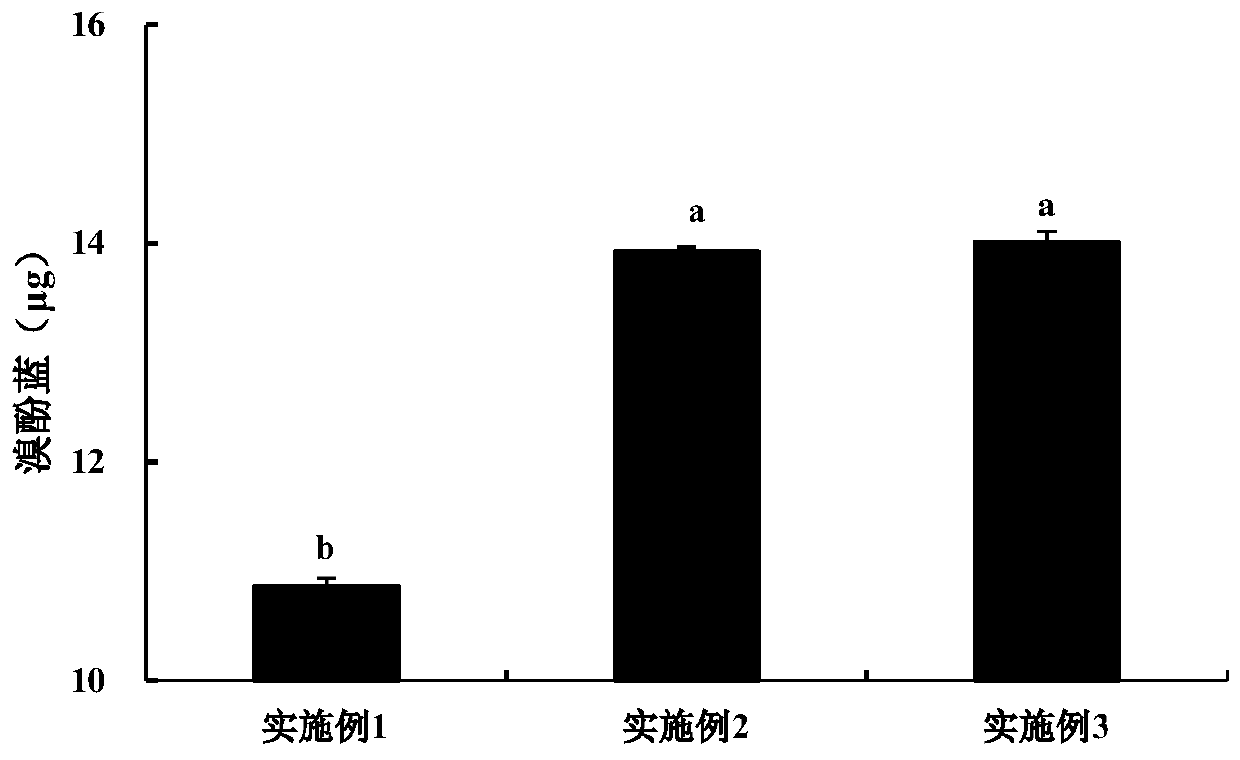

Embodiment 1

[0077] The method for improving the gel properties of mackerel myofibrillar protein comprises the following steps:

[0078] S1. Preparation of fish myofibrillar protein solution: take Spanish mackerel meat, cut into pieces, prepare fish myofibrillar protein solution, and set aside at 4°C;

[0079]Among them, the preparation method of the fish myofibrillar protein solution is as follows: at 4°C, take 20 g of fish meat, add 40 ml of 0.1 mol / L Tris-NaCl solution, homogenize at 1100 rpm for 1 min, centrifuge at 10000 g for 10 min, remove the supernatant, and take the precipitate A; add 40ml 0.1mol / L Tris-NaCl solution to the precipitate A, homogenize at 1100rpm for 1min, centrifuge at 10000g for 10min, remove the supernatant, and take the precipitate B; use 50ml 0.1mol / L Tris-NaCl solution for the precipitate B Dissolve, filter with ordinary absorbent cotton gauze, take the filtrate, centrifuge with a centrifuge at 10000g for 10min, remove the supernatant, take the precipitate C, ...

Embodiment 2

[0087] The method for improving the gel properties of mackerel myofibrillar protein comprises the following steps:

[0088] S1. Preparation of fish myofibrillar protein solution: take Spanish mackerel meat, cut into pieces, extract fish myofibrillar protein, prepare fish myofibrillar protein solution, and store at 4°C for later use;

[0089] Among them, the preparation method of the fish myofibrillar protein solution is as follows: at 4°C, take 20 g of fish meat, add 40 ml of 0.1 mol / L Tris-NaCl solution, homogenize at 1100 rpm for 1 min, centrifuge at 10000 g for 10 min, remove the supernatant, and take the precipitate A; add 40ml 0.1mol / L Tris-NaCl solution to the precipitate A, homogenize at 1100rpm for 1min, centrifuge at 10000g for 10min, remove the supernatant, and take the precipitate B; use 50ml 0.1mol / L Tris-NaCl solution for the precipitate B Dissolve, filter with ordinary absorbent cotton gauze, take the filtrate, centrifuge with a centrifuge at 10000g for 10min, re...

Embodiment 3

[0097] The method for improving the gel properties of mackerel myofibrillar protein comprises the following steps:

[0098] S1. Preparation of fish myofibrillar protein solution: take meat from Spanish mackerel, cut into pieces, extract fish myofibrillar protein, prepare fish myofibrillar protein solution, and store at 4°C for later use;

[0099] Among them, the preparation method of the fish myofibrillar protein solution is as follows: at 4°C, take 20 g of fish meat, add 40 ml of 0.1 mol / L Tris-NaCl solution, homogenize at 1100 rpm for 1 min, centrifuge at 10000 g for 10 min, remove the supernatant, and take the precipitate A; add 40ml 0.1mol / L Tris-NaCl solution to the precipitate A, homogenize at 1100rpm for 1min, centrifuge at 10000g for 10min, remove the supernatant, and take the precipitate B; use 50ml 0.1mol / L Tris-NaCl solution for the precipitate B Dissolve, filter with ordinary absorbent cotton gauze, take the filtrate, centrifuge with a centrifuge at 10000g for 10mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com