Industrial in-parallel water inlet two-stage disc filter

An industrial, disc-type technology, applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. The effect of good water quality, small footprint and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

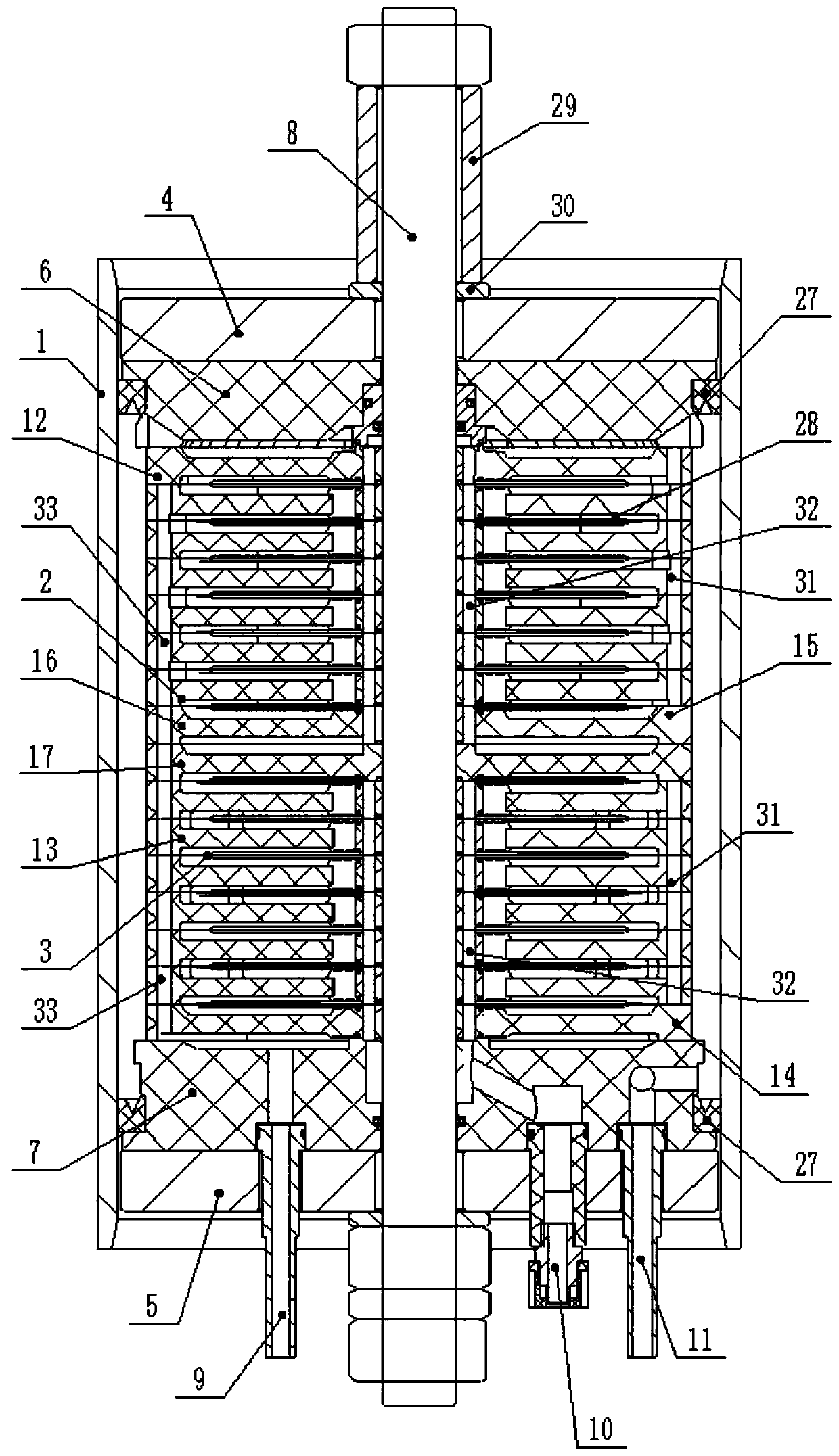

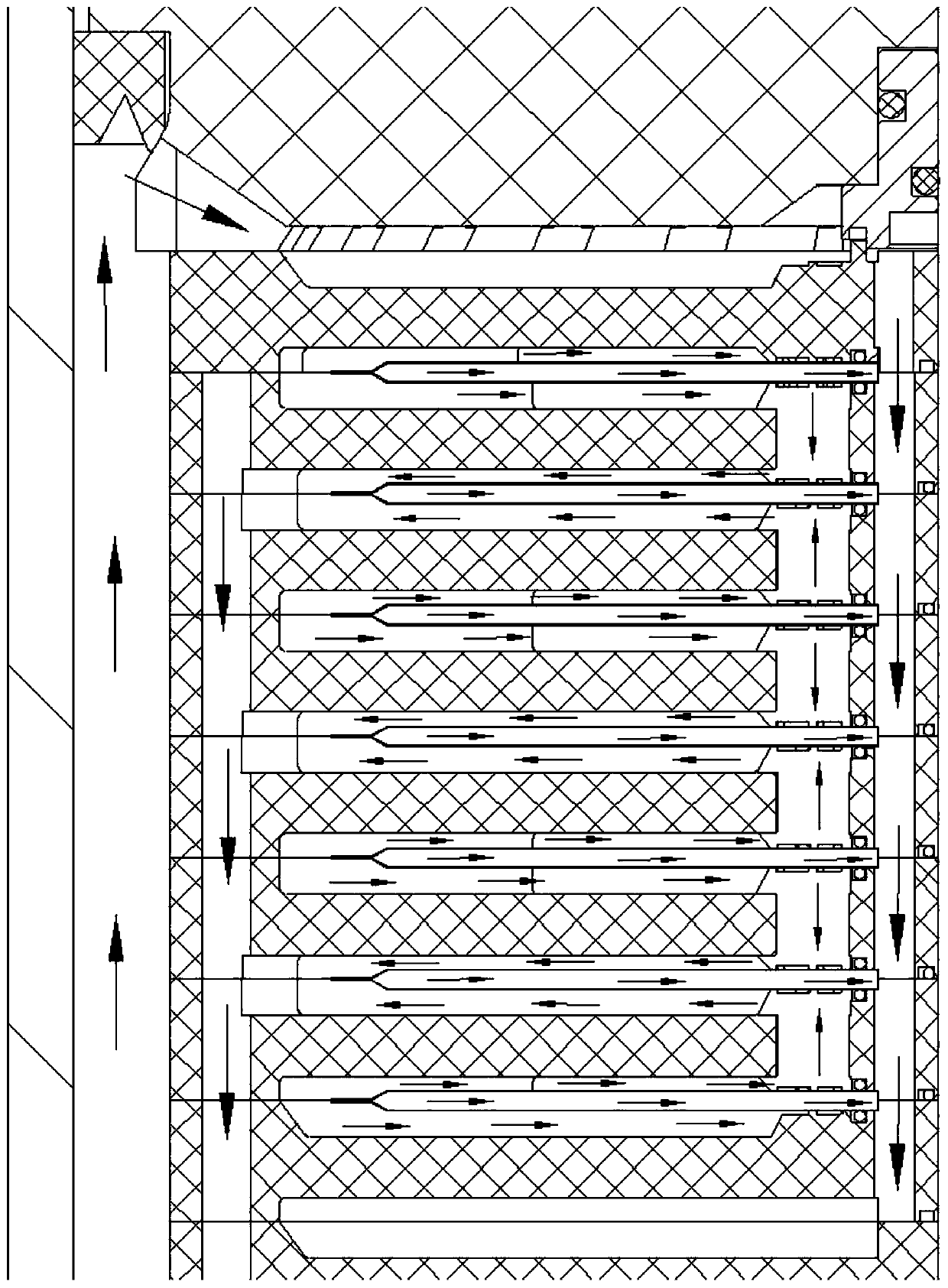

[0037] An industrial parallel water inlet two-stage disc filter, including an inner cylinder 1, the inner cylinder 1 is provided with a filter element, and the filter element includes a primary filter element 2 and a secondary filter element 3 arranged from top to bottom, The primary filter element 2 comprises an upper deflector plate 12 and a deflector plate 13, and the secondary filter element 3 comprises a lower deflector plate 14 and a deflector plate 13, and between the primary filter core 2 and the secondary filter core 3 Divide the guide plate 15, the divided guide plate 15 includes an upper divided guide plate 16 and a lower divided guide plate 17, the lower end of the inner cylinder 1 is provided with a sewa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com