Collecting pipe cap

A technology of collecting tubes and caps, which is applied in the field of caps of collecting tubes to achieve the effects of avoiding liquid leakage and ensuring sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

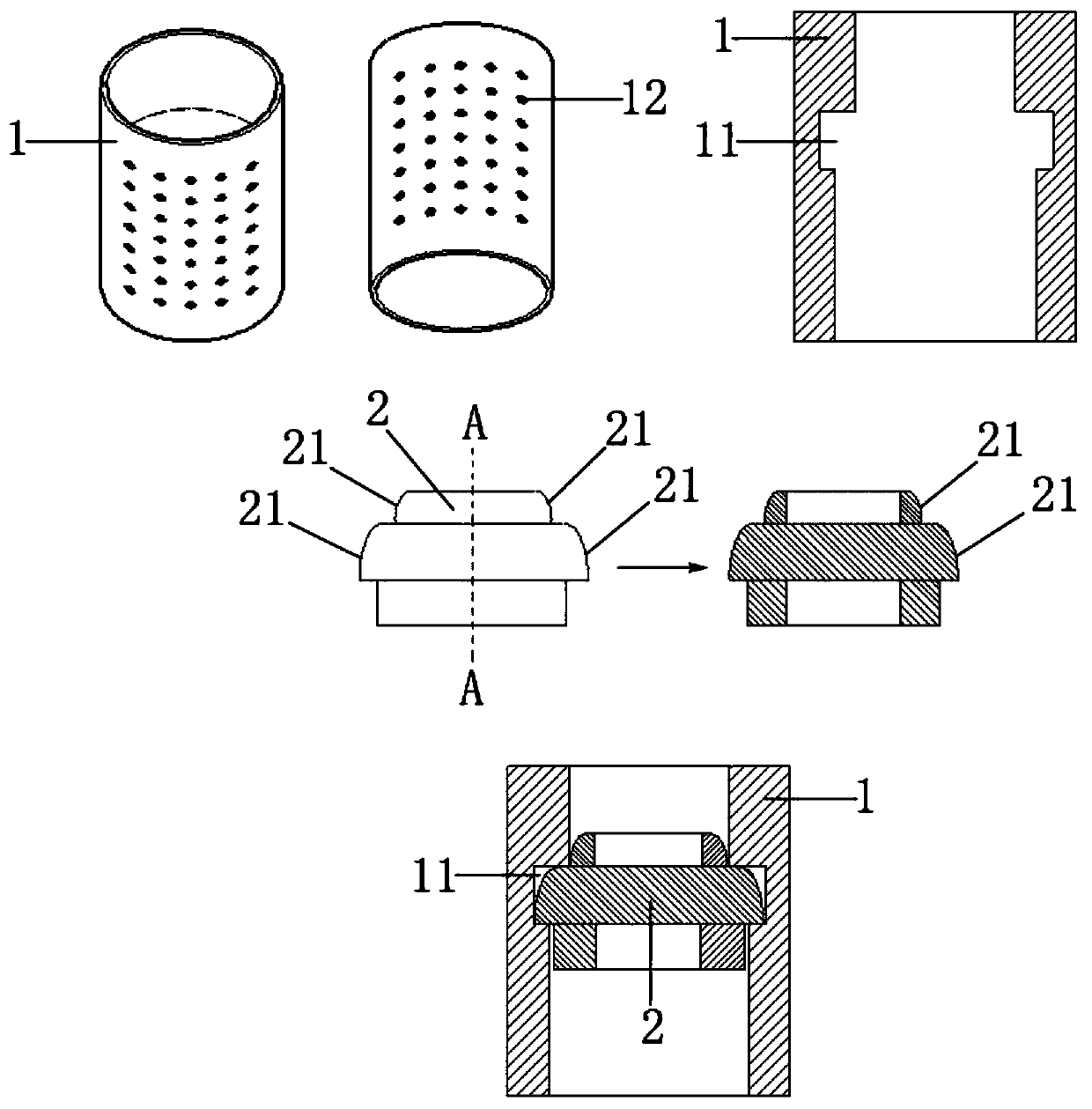

[0051] Please see attached figure 1 , figure 1 It is a schematic diagram of the three-dimensional structure above and below the body of the collection tube cap and the overall plan view, as well as a schematic plan view and A-A cross-sectional diagram of the closing plug of the collection tube cap of the present invention, and a schematic diagram of the assembly of the closing plug and the tube body. A collection tube cover, the collection tube cover includes a tube body 1 and a closure plug 2; the tube body 1 is in a hollow cylindrical structure; a top and a bottom of the tube body 1 are provided for placing the closure The slot 11 for placing the plug 2; the pipe body 1 is provided with an anti-skid structure 12; the diameter of the inner wall at the top of the slot 11 is smaller than the diameter of the inner wall at the bottom; the main body of the plug 2 has a three-layer structure, and the plug 2 The two sides of the upper and middle plug bodies are arc-shaped structure...

Embodiment 2

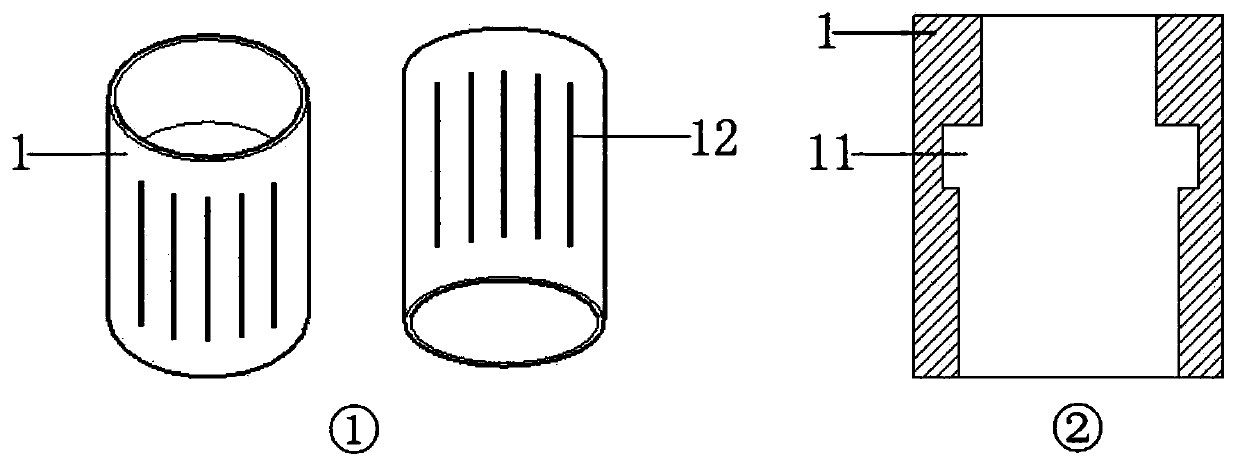

[0055] Please see attached Figure 3A , 3B , 3C, Figure 3A It is a schematic diagram of the three-dimensional structure above and below the tube body of the collection tube cover in Embodiment 2 of the present invention and a schematic diagram of the overall plan. Figure 3B It is an overall schematic plan view of a collection tube cap body in Embodiment 3 of the present invention (wherein, ① is a schematic plan view of a closure plug, ② is a schematic cross-sectional view of a dotted line A-A of a closure plug, and ③ is a top view of a cross-sectional view of a dotted line A-A of a partial structure of a closure plug , ④ is the dotted line A-A cross-sectional top view of the local structure of the closure plug), Figure 3C It is a schematic plan view of the connection between a collection tube cap and a collection tube in Embodiment 2 of the present invention. This embodiment is basically the same as Embodiment 1, the difference is that the connection between the pipe bod...

Embodiment 3

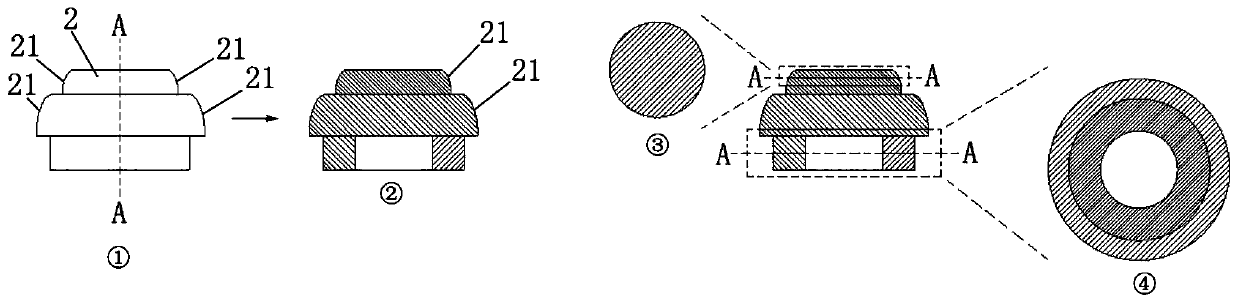

[0057] Please see Figure 4A , 4B , 4C, 4D, Figure 4A It is a schematic diagram of the three-dimensional structure above and below the tube body of the collection tube cap of Embodiment 3 of the present invention and a schematic diagram of the overall plan. Figure 4B It is the overall and partial schematic diagram of a collection pipe cap body in Embodiment 3 of the present invention (wherein, ① is the overall plan view of the pipe body; ② is the dotted line AA cross-sectional perspective view of the local structure of the pipe body; ③ is the dotted line of the local structure of the pipe body AA section bottom view; ④ is the dotted line AA section top view of the local structure of the pipe body), Figure 4C It is a schematic plan view of the bottom of the collection tube cover and the nozzle of the collection tube in Embodiment 3 of the present invention (wherein, ① is a top view of the bottom structure of the tube body; ② is a top view of the connection structure of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com