Bare concrete

A technology of fair-faced concrete and water-reducing agent, applied in the field of concrete, which can solve the problems that clear-water concrete is easily eroded by rainwater, loses decorative meaning of clear-water concrete, and affects the service life of clear-water concrete. It is not easy to achieve decorative effects, not easy to be corroded by acid rain The effect of enhanced impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

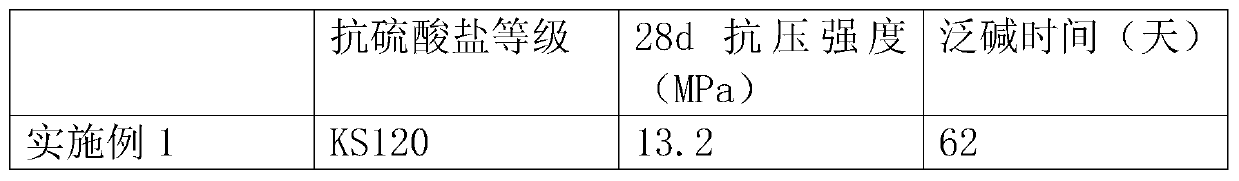

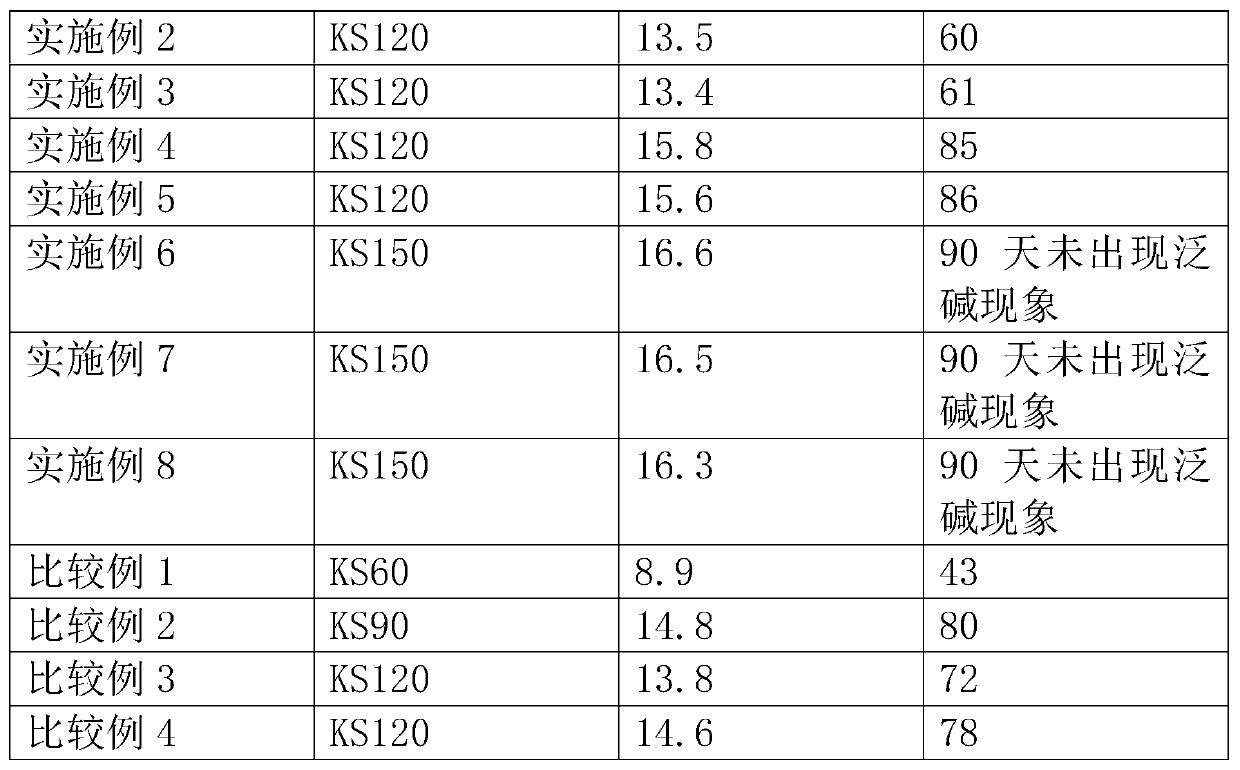

Examples

Embodiment 1

[0060] A kind of fair-faced concrete, comprises the component of following mass parts:

[0061] 16kg of water; 20kg of Portland cement; 5kg of slag powder; 7kg of limestone powder; 100kg of stone; 85kg of sand; 3kg of hollow glass microspheres; 2kg of ethylene-vinyl acetate copolymer;

[0062] In this embodiment, the particle size of the hollow glass microspheres is 20 μm.

[0063] The preparation method of fair-faced concrete is as follows:

[0064] S1. In the cement mixer, under normal temperature conditions, add 20kg of Portland cement and stir at a speed of 150r / min;

[0065] S2. Add 16 kg of water, 3 kg of hollow glass microspheres, 2 kg of ethylene-vinyl acetate copolymer, 0.8 kg of silane impregnating agent, and 0.1 kg of vaseline while stirring, and obtain a premix after stirring evenly;

[0066] S3. Add 5kg of slag powder, 7kg of limestone powder, 100kg of limestone, and 85kg of sand to the sand and gravel mixer at room temperature, and stir at a speed of 180r / min t...

Embodiment 2

[0072] A kind of fair-faced concrete, comprises the component of following mass parts:

[0073] 17kg of water; 18kg of Portland cement; 6kg of slag powder; 8kg of limestone powder; 103kg of stone; 80kg of sand; 4kg of hollow glass microspheres; 1kg of ethylene-vinyl acetate copolymer;

[0074] In this embodiment, the particle size of the hollow glass microspheres is 23 μm.

[0075] The preparation method of fair-faced concrete is as follows:

[0076] S1. In the cement mixer, under normal temperature conditions, add 18kg of Portland cement and stir at a speed of 150r / min;

[0077] S2. Add 17kg of water, 4kg of hollow glass microspheres, 1kg of ethylene-vinyl acetate copolymer, 1kg of silane impregnating agent, and 0.3kg of vaseline while stirring, and stir to obtain a premix;

[0078] S3. In the gravel mixer, under normal temperature conditions, add 6kg of slag powder, 8kg of limestone powder, 103kg of stone, and 80kg of sand, stir at a speed of 180r / min, and obtain aggregate...

Embodiment 3

[0084] A kind of fair-faced concrete, comprises the component of following mass parts:

[0085] 18kg of water; 15kg of Portland cement; 4kg of slag powder; 6kg of limestone powder; 105kg of stone; 83kg of sand; 5kg of hollow glass microspheres; 1.5kg of ethylene-vinyl acetate copolymer;

[0086] In this embodiment, the particle size of the hollow glass microspheres is 25 μm.

[0087] The preparation method of fair-faced concrete is as follows:

[0088] S1. In a cement mixer, under normal temperature conditions, add 15kg of Portland cement and stir at a speed of 150r / min;

[0089] S2. Add 18 kg of water, 5 kg of hollow glass microspheres, 1.5 kg of ethylene-vinyl acetate copolymer, 0.5 kg of silane impregnating agent, and 0.5 kg of vaseline while stirring, and obtain a premix after stirring evenly;

[0090] S3. In the gravel mixer, under normal temperature conditions, add 4kg of slag powder, 6kg of limestone powder, 105kg of stone, and 83kg of sand, stir at a speed of 180r / mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com