Early-stage high-expansion cement-based grouting material

A grouting material and cement-based technology, applied in the field of grouting material, can solve the problems of reducing the use effect of materials and small effective contact area, and achieve the effect of enhancing the application effect and increasing the effective contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

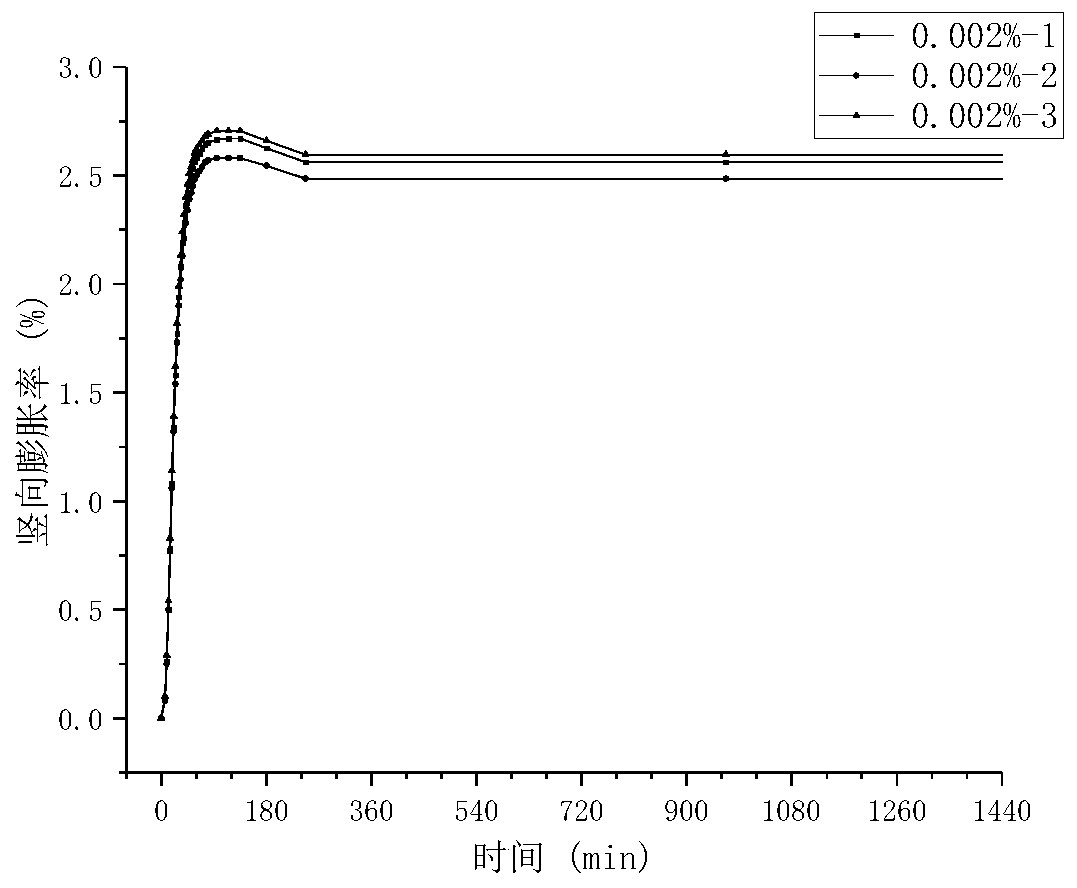

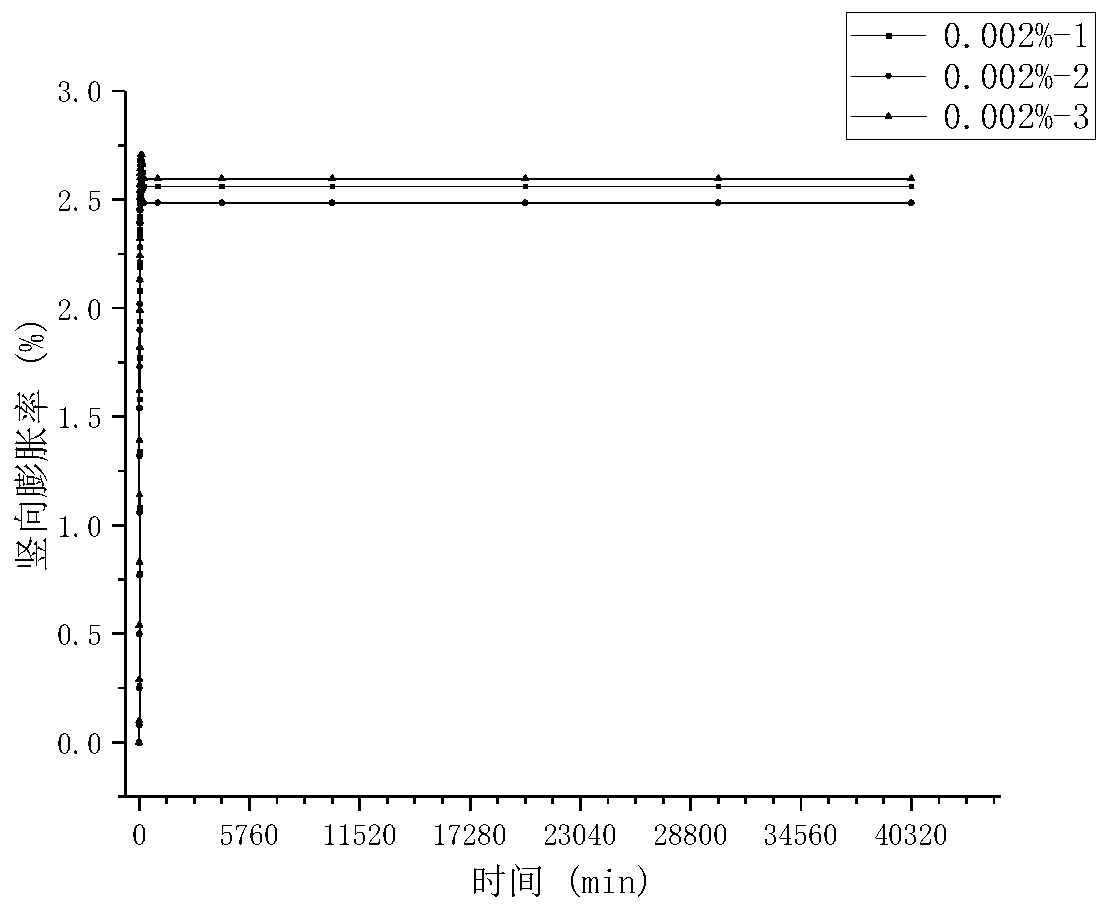

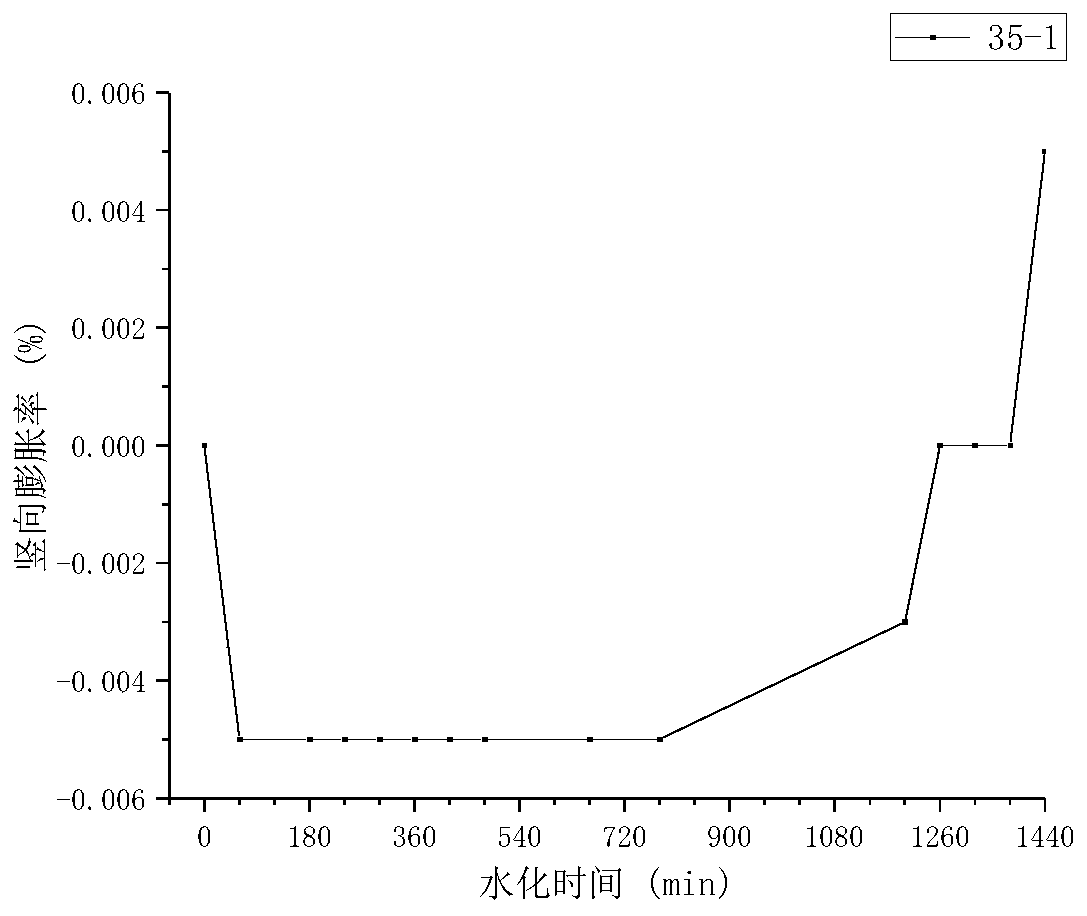

[0019] As shown in the figure: an early high-expansion cement-based grouting material according to the present invention, its raw materials are as follows in parts by weight: cement 300-400kg, admixture 30-40kg, machine-made sand 520-650kg, water-retaining agent 0.2-0.4 kg, 1.0-2.5kg of water reducer, 5-10kg of expansion agent, 1-2kg of defoamer, a small amount of gas generating agent, and 130-140kg of stirring water. Preferably, the cement is 42.5 grade ordinary Portland cement, and the expansion agent is calcium aluminate-magnesia-calcium oxide composite high-efficiency expansion agent. The water reducer is a modified naphthalene-based water reducer, a carboxylic acid high-efficiency water reducer, and of course a sulfonic acid high-efficiency water reducer, but it is preferably a dry powder polycarboxylate high-efficiency water reducer. Efficiency ≥ 25%.

[0020] As a more specific scheme of the above scheme, the material selection and dosage of a kind of early-stage high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com