Method for improving carburization temperature by microalloying and surface carburization method for low-carbon steel

A technology of micro-alloying and low-carbon steel, which is applied in the field of carburizing heat treatment of low-carbon steel or low-carbon alloy steel, can solve the problems of low carburizing temperature, large energy consumption, and long process cycle, so as to shorten the cycle and reduce the Effect of diffusion time and energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The workpieces produced by 18CrNiMo7-6 carburizing steel are widely used in wind power, port reducer and high-speed locomotive and other industries. The main chemical composition of 18CrNiMo7-6 experimental steel: 0.17%C, 0.18%Si, 0.60%Mn, 1.50%Cr, 1.48%Ni, 0.30%Mo. The 18CrNiMo7-6 steel with this chemical composition is designed for microalloying, and Nb is added to make the Nb content in the alloy 0.06%.

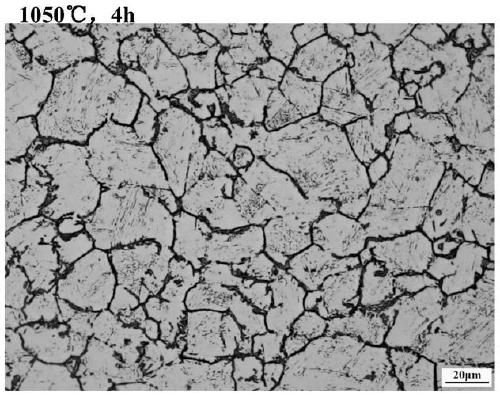

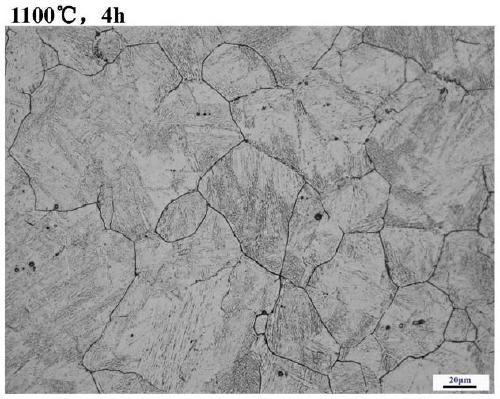

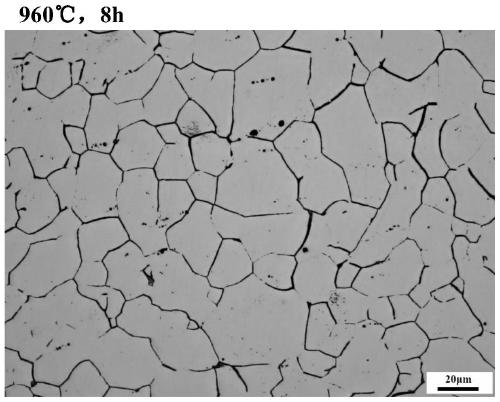

[0043] Then the grain size of the 18CrNiMo7-6 steel sample after microalloying was determined. The experimental steel sample is placed in a vacuum furnace, and the temperature is raised to the holding temperature with the furnace. After holding for a certain period of time, it is taken out of the furnace and quenched in oil. The sample after quenching was prepared for metallography, and the structure with obvious grain boundaries was obtained after corrosion, and the grain size was measured.

[0044] Experimental conditions: holding temperatures were 900°C, 950°C,...

Embodiment 2

[0050] 20CrMn carburizing steel is widely used in structural parts such as gear shafts, gears, water pump rotors, clutches, small shafts, mandrels and bolts that work at high speeds and high loads without strong impact loads. The main chemical composition of the experimental steel: 0.18%C, 0.20%Si, 1.05%Mn, 1.17%Cr. The 20CrMn steel with this chemical composition is micro-alloyed, and Ti is added to make the Ti content in the alloy 0.06%, so that the 20CrMnTi carburizing steel with the highest market share in our country is obtained.

[0051] Grain size determination was then carried out on the 20CrMnTi steel samples. The experimental steel sample is placed in a vacuum furnace, and the temperature is raised to the holding temperature with the furnace. After holding for a certain period of time, it is taken out of the furnace and quenched in oil. The sample after quenching was prepared for metallography, and the structure with obvious grain boundaries was obtained after corros...

Embodiment 3

[0057] 17Cr2Ni2Mo steel is a localized brand of Cr-Ni-Mo gear steel developed by German ZF company. It is widely used in the production of gears, bevel gears and other transmission parts, reducer parts, butterfly wheels, friction parts, etc. The main chemical composition of the experimental steel: 0.18%C, 0.22%Si, 0.55%Mn, 1.65%Cr, 1.70%Ni, 0.28%Mo. The 17Cr2Ni2Mo steel with this chemical composition is designed for microalloying, and the combined microalloying elements of Nb and V are added, so that the Nb content in the alloy is 0.06%, and the V content is 0.10%.

[0058] Subsequently, the grain size determination of the microalloyed 17Cr2Ni2Mo steel samples was carried out. The experimental steel sample is placed in a vacuum furnace, and the temperature is raised to the holding temperature with the furnace. After holding for a certain period of time, it is taken out of the furnace and quenched in oil. The sample after quenching was prepared for metallography, and the struc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com