A kind of aluminum alloy anode plane pattern dyeing method

A technology of flat pattern and dyeing method, which is applied in the direction of anodic oxidation, surface reaction electrolytic coating, coating, etc., which can solve the problems that the pattern does not have the metal texture of aluminum alloy anodized film, the color fading process is unstable, and colorful patterns cannot be made. , to achieve the effect of convenient electrolytic dyeing, diversified product appearance and strong pattern stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

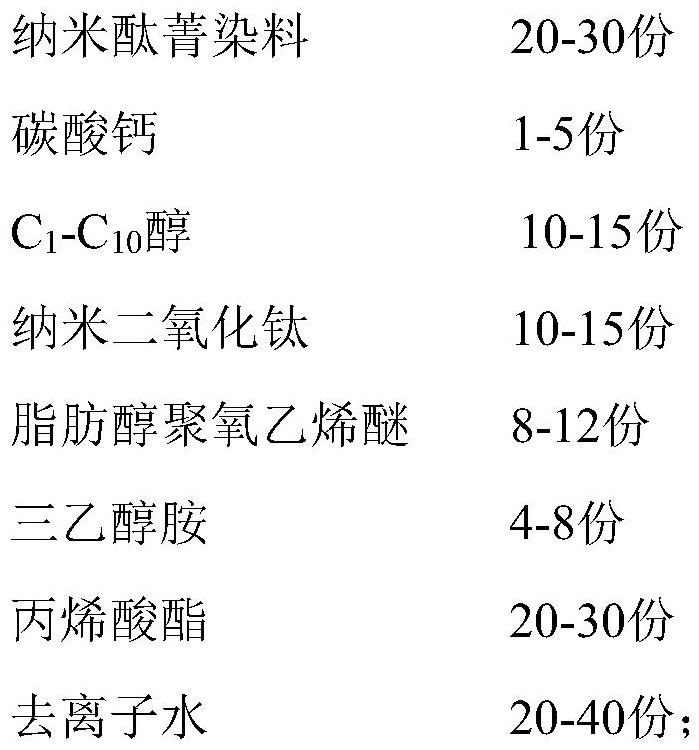

Method used

Image

Examples

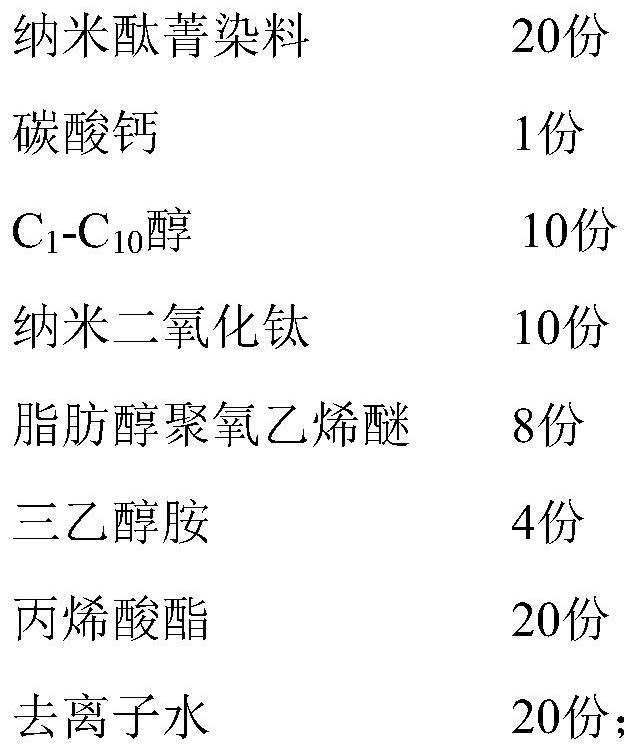

Embodiment 1

[0025] A method for dyeing an aluminum alloy anode planar pattern, comprising the steps of:

[0026] 1) Decontamination treatment: Use neutral degreasing agent QX0116 to soak for 30 seconds at a temperature of 50°C to remove stains on aluminum products;

[0027] 2) Anodizing treatment: hang the aluminum product decontaminated in step 1) firmly with a jig, and place it in a H 2 S0 4 The voltage connected to the anode tank is 5V and the current is oxidized for 50 minutes, so that the surface of the aluminum product forms an aluminum oxide layer with nano-pores;

[0028] 3) Surface adjustment treatment: put the oxidized aluminum product in step 2) into pure water with a pH value of 4, rinse it clean, and then put it into an ultrasonic device with an acid solution with a concentration of 18g / L for ultrasonication Treatment, the current used by the ultrasonic device is 4A, the ultrasonic treatment time is 5min, and then washed and dried with deionized water;

[0029] 4) Pattern ...

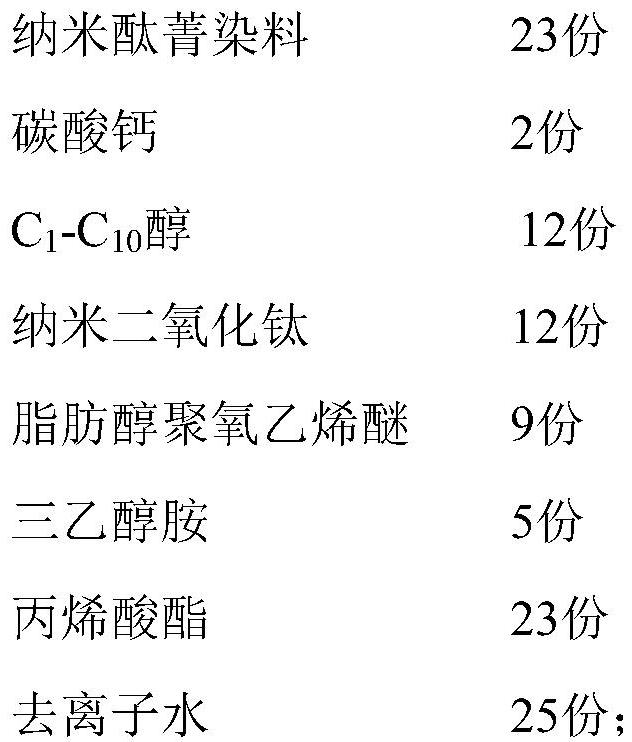

Embodiment 2

[0041] A method for dyeing an aluminum alloy anode planar pattern, comprising the steps of:

[0042] 1) Decontamination treatment: Use neutral degreasing agent QX0116 to soak for 37 seconds at a temperature of 52°C to remove stains on aluminum products;

[0043] 2) Anodizing treatment: hang the aluminum product decontaminated in step 1) firmly with a jig, and place it in a H 2 S0 4 The voltage connected to the anode tank is 6V and the current is oxidized for 55 minutes, so that the surface of the aluminum product forms an aluminum oxide layer with nanopores;

[0044] 3) Surface adjustment treatment: put the oxidized aluminum product in step 2) into pure water with a pH value of 5 and rinse it clean, then put it into an ultrasonic device with an acid solution with a concentration of 19g / L for ultrasonication Treatment, the current used by the ultrasonic device is 4.3A, the ultrasonic treatment time is 6min, and then washed and dried with deionized water;

[0045] 4) Pattern ...

Embodiment 3

[0057] A method for dyeing an aluminum alloy anode planar pattern, comprising the steps of:

[0058] 1) Decontamination treatment: Use neutral degreasing agent QX0116 to soak for 45 seconds at a temperature of 53°C to remove stains on aluminum products;

[0059] 2) Anodizing treatment: hang the aluminum product decontaminated in step 1) firmly with a jig, and place it in a H 2 S0 4 The voltage connected to the anode tank is 7V and the current is oxidized for 60 minutes, so that the surface of the aluminum product forms an aluminum oxide layer with nano-sized pores;

[0060] 3) Surface adjustment treatment: put the oxidized aluminum product in step 2) into pure water with a pH value of 6 and rinse it clean, then put it into an ultrasonic device with an acid solution with a concentration of 20g / L for ultrasonication Treatment, the current used by the ultrasonic device is 4.5A, the ultrasonic treatment time is 7min, and then washed and dried with deionized water;

[0061] 4) P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com