Direct-drive barrier gate

A kind of gate machine, direct-drive technology, applied in the field of gates, can solve the problems that the reducer can not be used normally, affect the scope of application of the gate, and the service life of the reducer is short, so as to improve the use range, avoid shaking and unstable, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

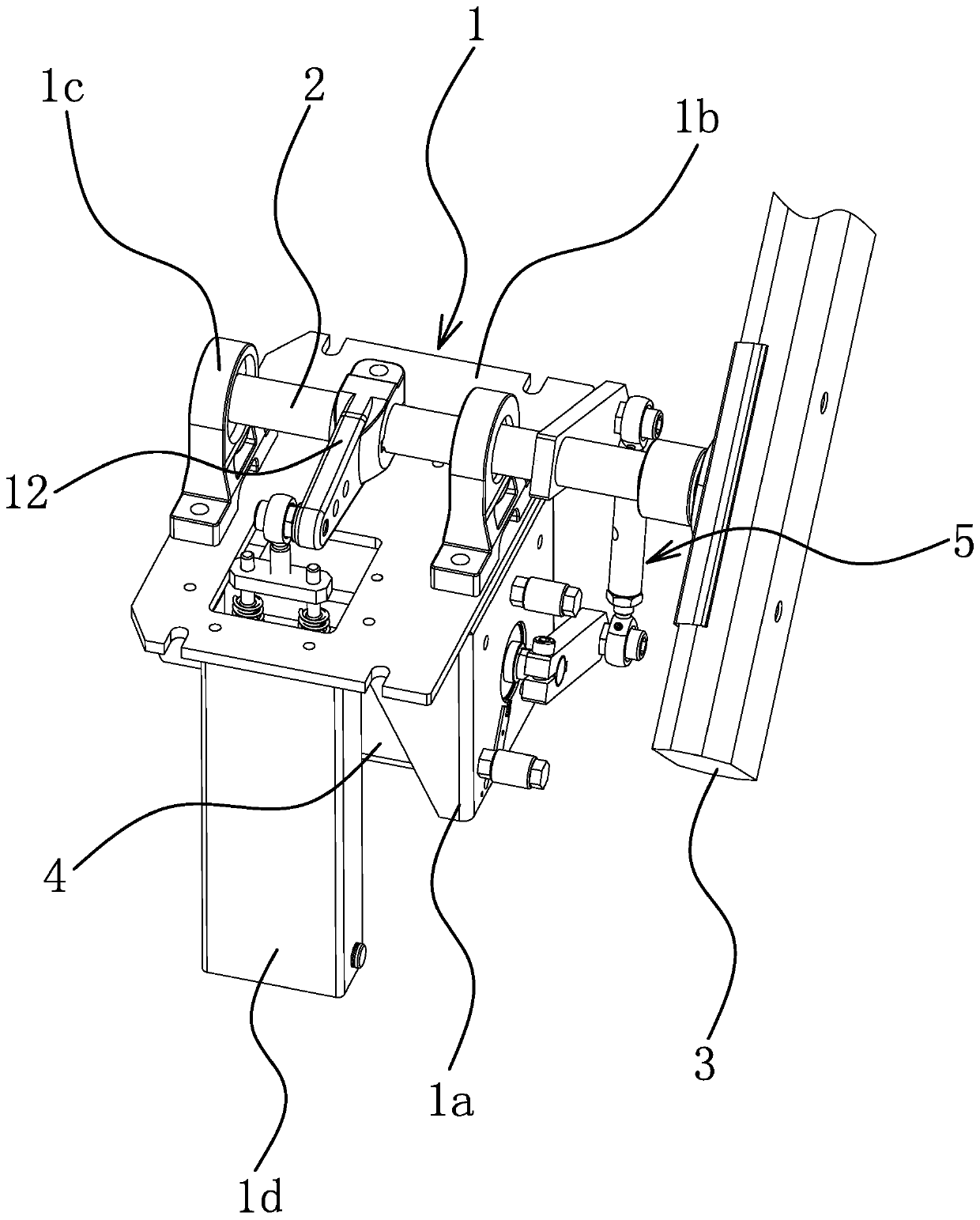

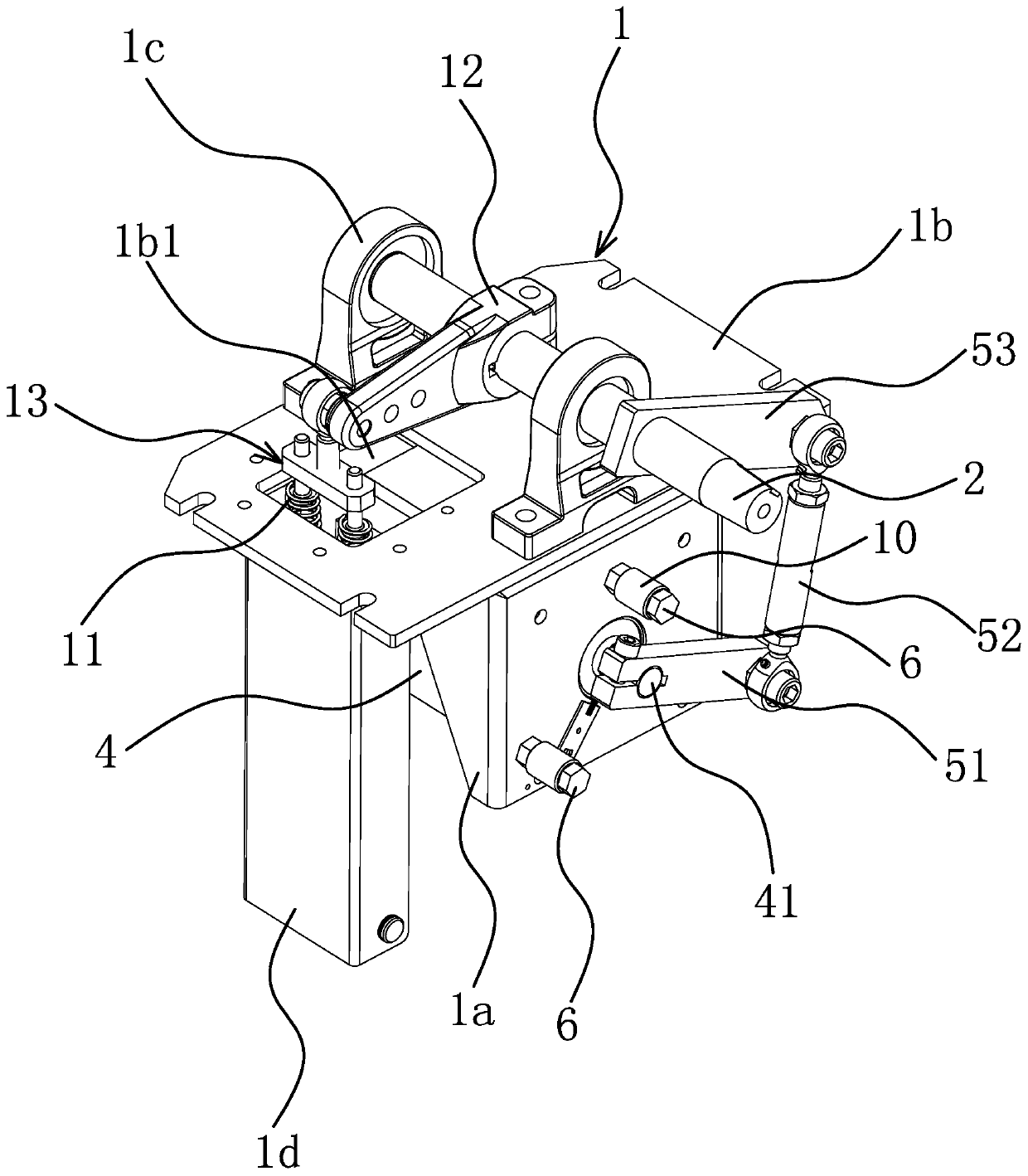

[0022] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

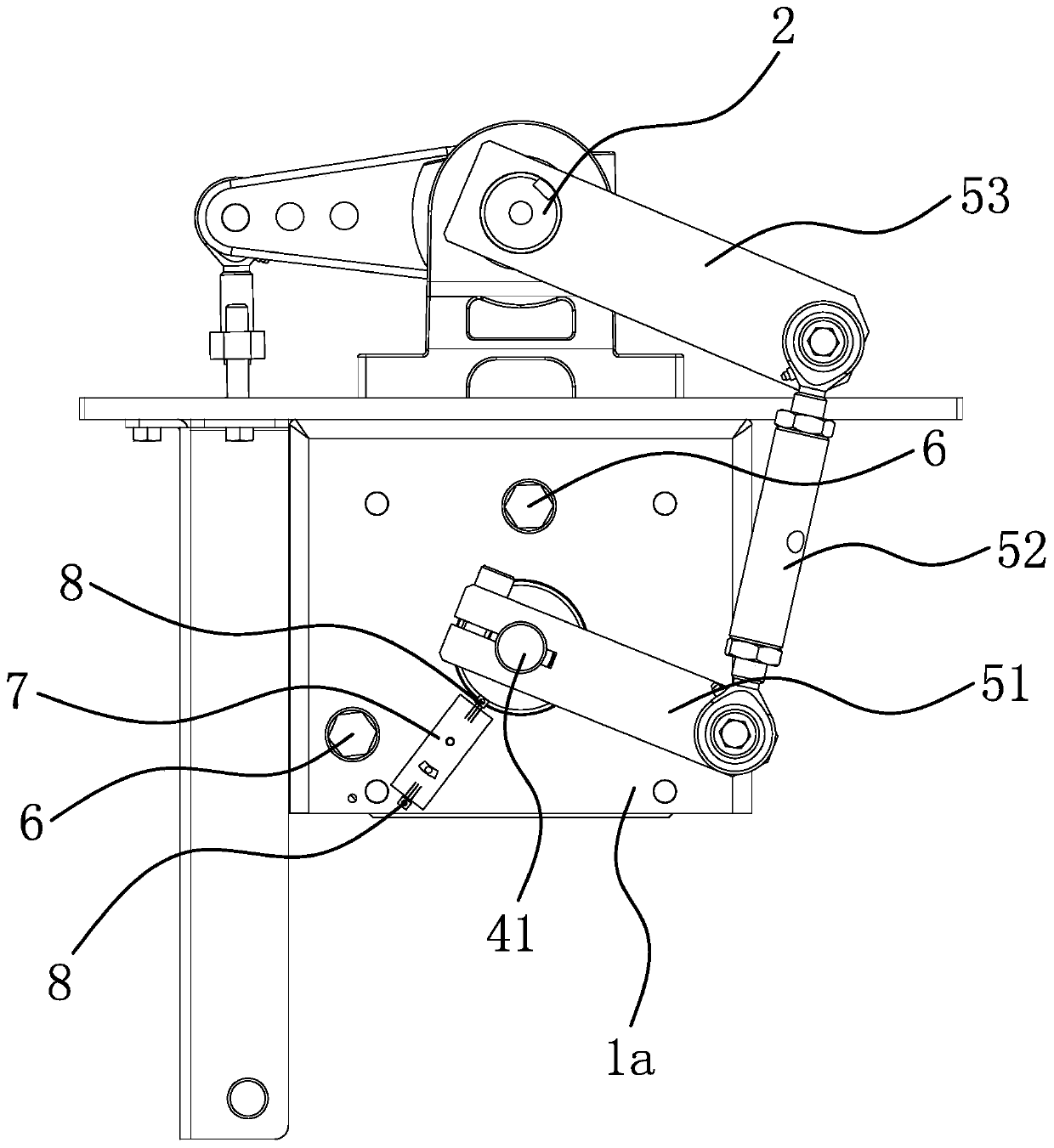

[0023] Such as figure 1 with figure 2 As shown, the direct-drive barrier gate includes a base 1, and the base 1 includes a backing plate 1b, two bearing housings 1c fixed on the upper surface of the backing plate 1b, a fixed plate 1a fixed on the lower surface of the backing plate 1b, and a fixing frame 1d, the output shaft 2 is rotatably connected to the bearing seat 1c, the gate lever 3 is fixed at one end of the output shaft 2, and the motor 4 is fixed on the fixed plate 1a.

[0024]Further, the motor 4 is a low-speed high-torque permanent magnet synchronous motor, and the motor 4 drives the output shaft 2 to rotate through the link mechanism 5. The link mechanism 5 includes a connecting rod one 51, a connecting rod t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com