Hydraulic medium filter device used for automatic transmission

An automatic transmission, hydraulic medium technology, applied in the direction of fluid pressure actuation device, fluid pressure actuation system components, mechanical equipment, etc., can solve the problems of low utilization rate of filter medium, complicated installation process, short service life, etc. Small occupied space, simple installation process, and the effect of reducing cavitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

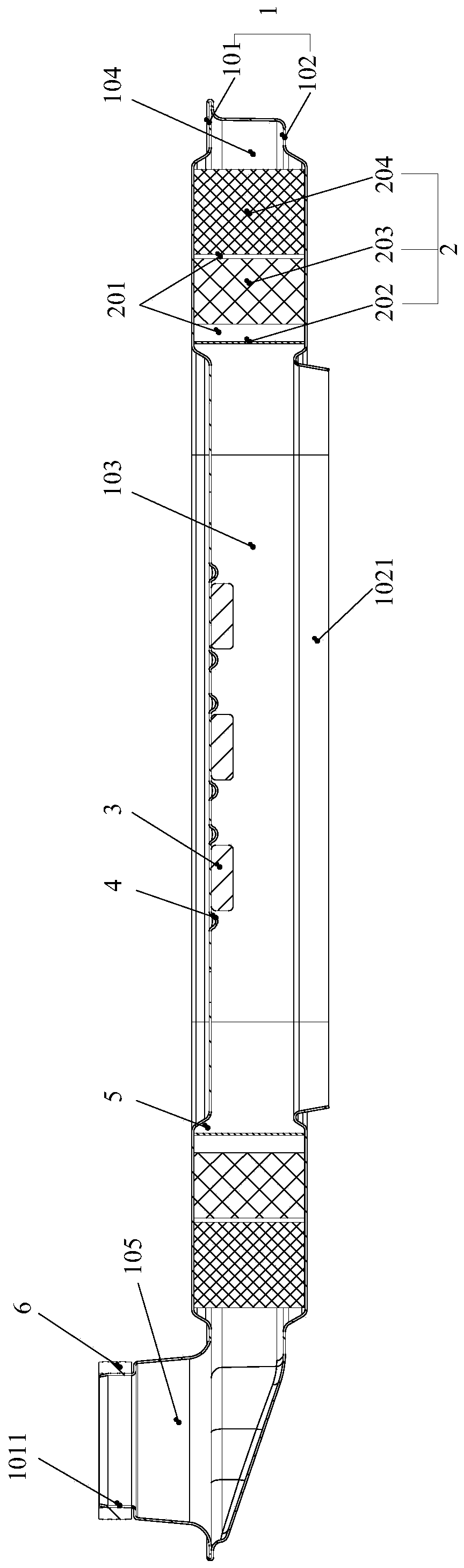

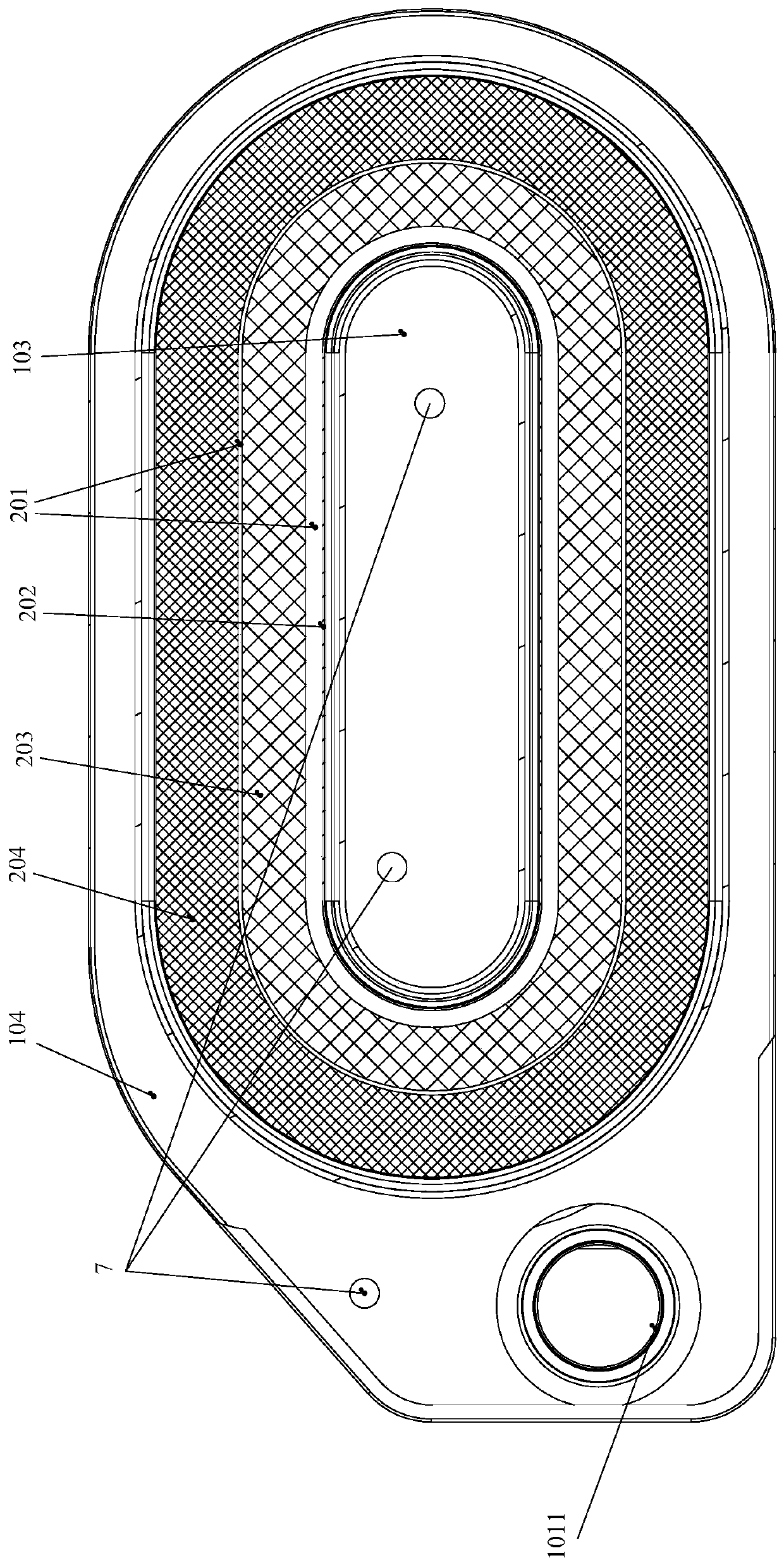

[0038] refer to figure 1 and figure 2 , the hydraulic medium filter device includes a housing 1 and an annular filter medium assembly 2 .

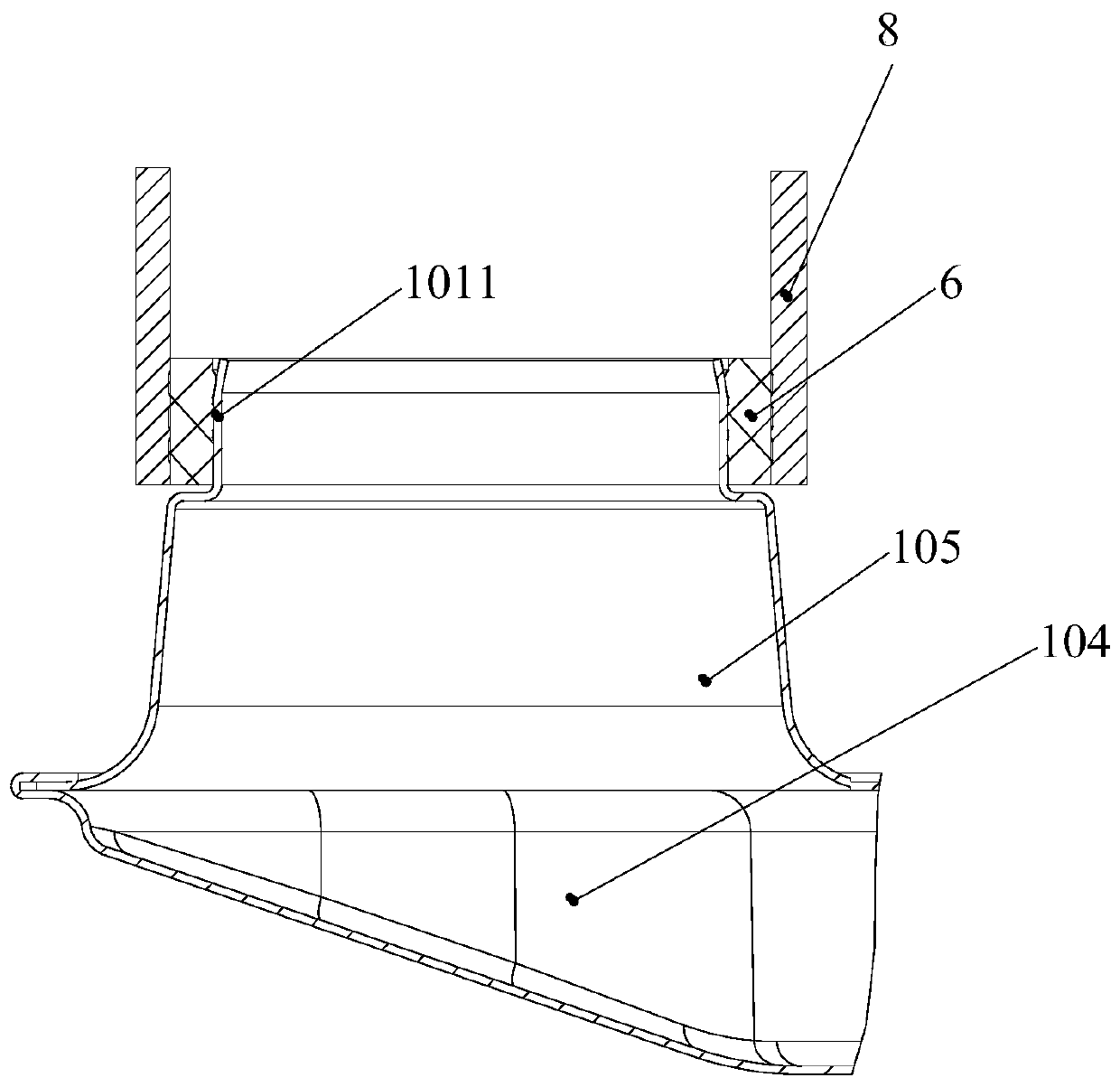

[0039] The housing 1 is provided with an annular filter medium assembly installation cavity 5, and the annular filter medium assembly 2 is fixed in the annular filter medium assembly installation cavity 5 by thermosetting glue, and the inner cavity of the housing 1 is divided into an inner ring cavity 103 and the outer ring cavity 104 . In order to prevent the annular filter medium assembly 2 from moving in the annular filter medium assembly installation cavity 5 and act as a reinforcing rib, the height of the annular filter medium assembly installation cavity 5 is higher than that of the outer ring cavity 104 .

[0040] The casing 1 includes an upper casing 101 and a lower casing 102 , the edge of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com