A small electric arc melting furnace

An electric arc melting furnace, small-scale technology, applied in the direction of furnace, charge, crucible furnace, etc., can solve the problems of arc ignition failure, arc interruption, arc ignition rod position rise, etc., to improve stability and success rate, improve success rate, The effect of reducing the likelihood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

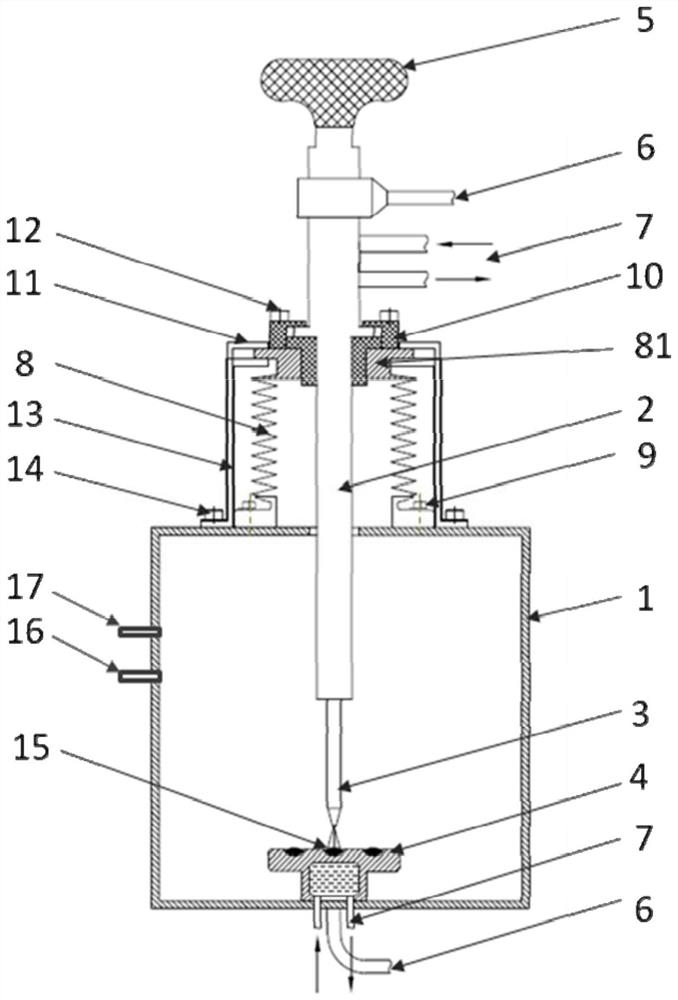

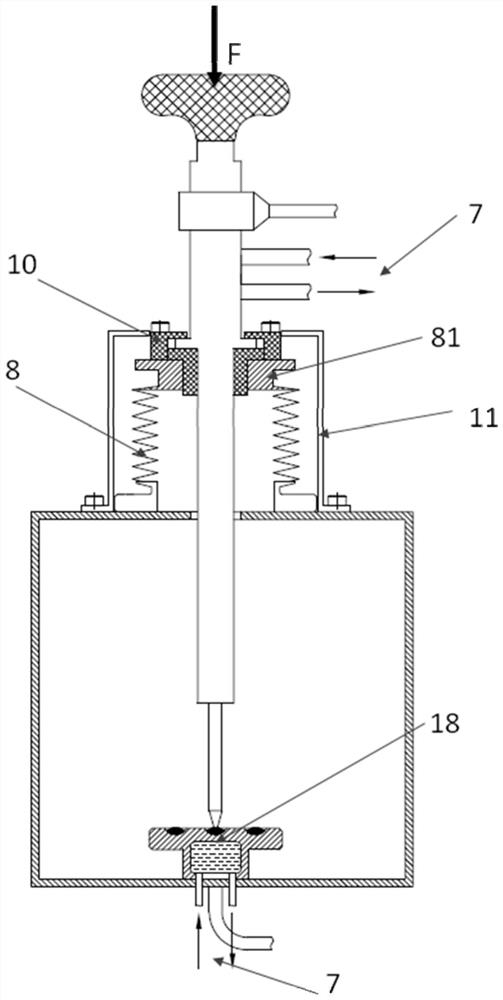

[0018] The embodiment of the invention discloses a small-sized electric arc melting furnace, which includes a vacuum furnace, and an arc strike rod whose lower end is inserted in the vacuum furnace. The lower end of the arc strike rod is fixedly equipped with a tungsten needle, and the upper end is connected through an electrode The column is connected to the power supply. There are several water-cooled crucibles with metal molten pools at the bottom of the vacuum furnace. The metal molten pools are used to place metal melts. The metal bellows on the arc strike rod, and the lower end of the metal bellows is installed on the shell wall of the vacuum furnace, and the upper end is connected with the arc strike rod through a connecting piece; the metal bellows is also provided with a bellows lower limit frame and a bellows The upper limit frame and the bellows lower limit frame are used for the lower limit when vacuuming and filling inert gas, and the bellows upper limit frame is u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com