Intelligent working system for unmanned engineering machinery and working method

A technology for construction machinery and unmanned driving, applied in control/regulation systems, motor vehicles, two-dimensional position/channel control, etc., can solve problems such as inability to realize intelligent operation, endangering the physical and mental health of drivers, and poor operation accuracy. , to achieve the effect of eliminating blind spots in the shooting field of vision, improving work efficiency and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

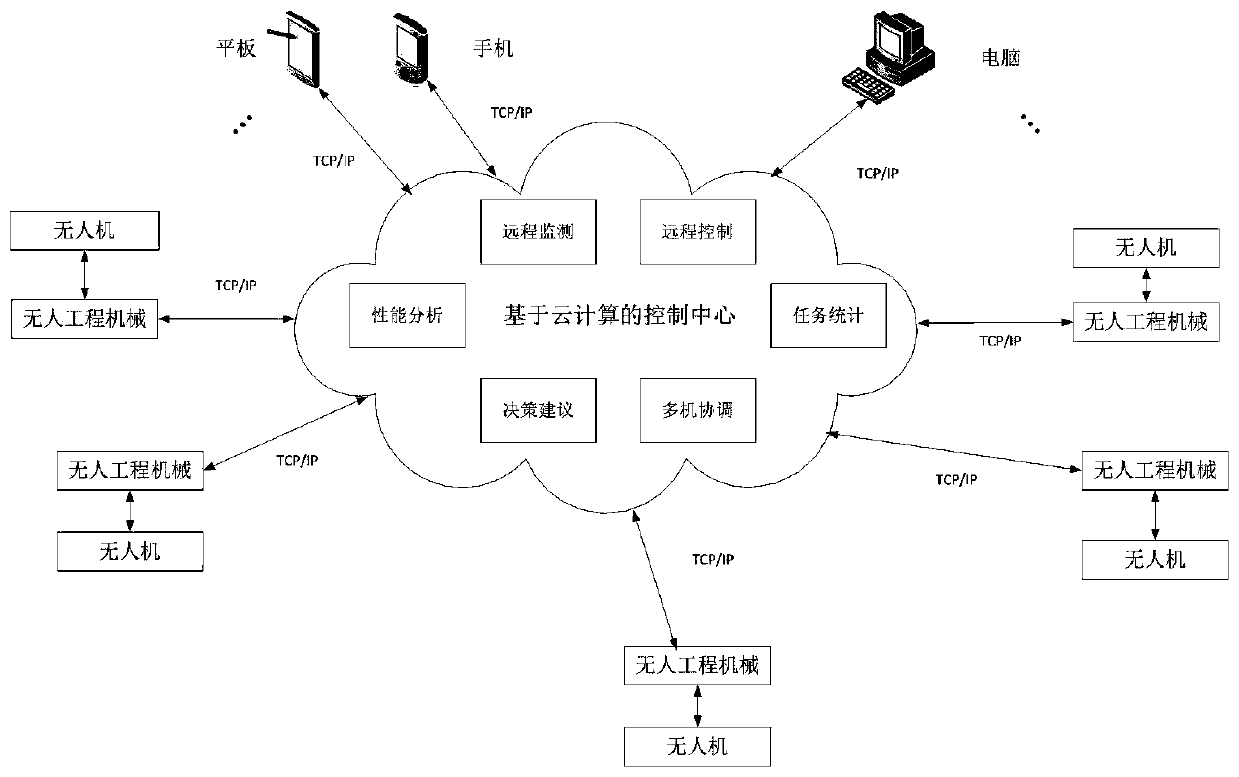

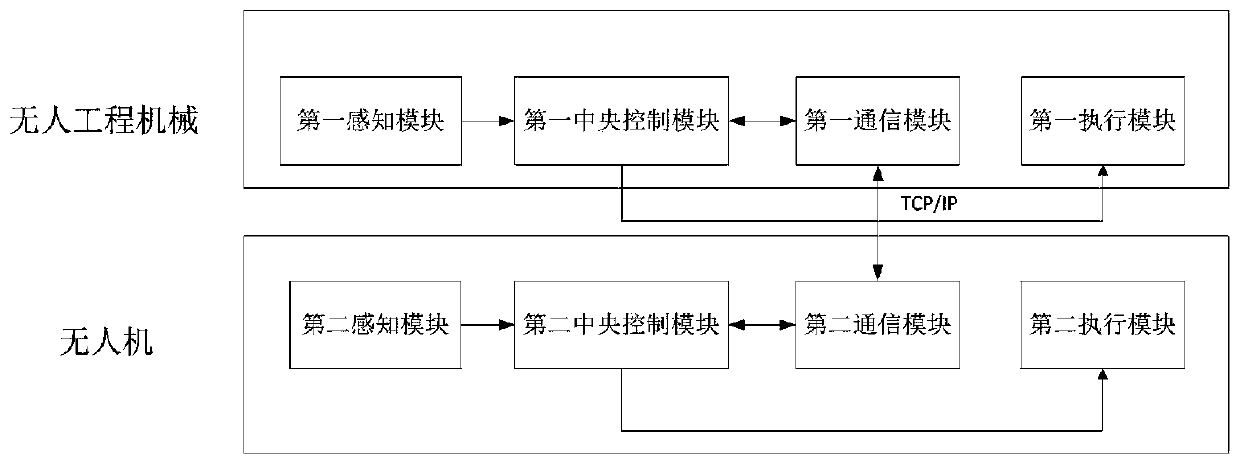

[0044] Specific implementation mode 1. Combination Figure 1 to Figure 7 In this embodiment, the intelligent operation system of unmanned construction machinery includes unmanned aerial vehicles, unmanned construction machinery and a control center based on cloud computing; each unmanned aerial vehicle corresponds to one unmanned construction machinery;

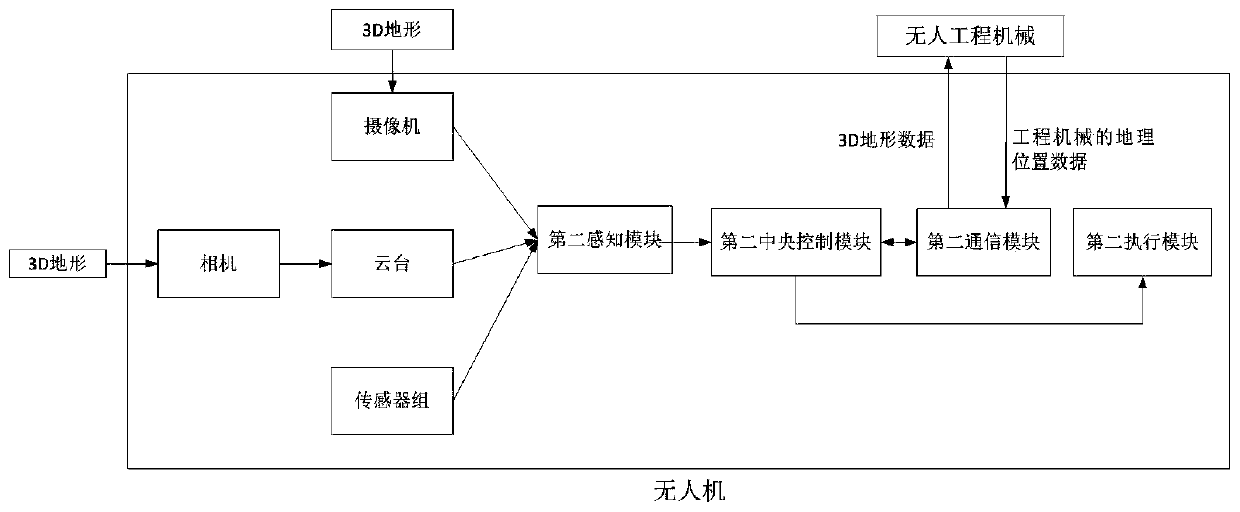

[0045] The unmanned aerial vehicle utilizes the equipped camera to collect working terrain data, and transmits the data to the unmanned engineering machinery in the form of TCP / IP; then the unmanned engineering machinery summarizes the data transmitted by the unmanned aerial vehicle and the operating status data collected by itself, Obstacles and working terrain and other data; then unmanned construction machinery realizes unmanned navigation, intelligent obstacle avoidance, multi-machine coordination and intelligent operation based on the summarized data; The form is transmitted to the cloud computing control center; finally...

specific Embodiment approach 2

[0071] Specific embodiment two, combine Figure 8 Describe this embodiment, this embodiment is the operation method of an intelligent operation system of an unmanned construction machine described in the first embodiment; specifically, it is realized by the following steps:

[0072] Step 1, the UAV detects the 3D terrain of the working environment of the construction machinery, and transmits it to the unmanned construction machinery through the second communication module;

[0073] Step 2, the unmanned engineering machinery receives the data sent by the drone and collects the vehicle state, 3D terrain, work task progress, operation medium, actual scene and obstacle data in real time according to the first perception module, and transmits the above data in real time To the data processing module and cloud-based control center;

[0074] Step 3, the construction machine sends a control instruction to the first execution module according to the calculation and processing of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com