Method and plant for producing olefin

一种烯烃、设备的技术,应用在化学仪器和方法、碳氢化合物、碳氢化合物等方向,达到增加使用时间、减少变化、避免控制成本和复杂性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

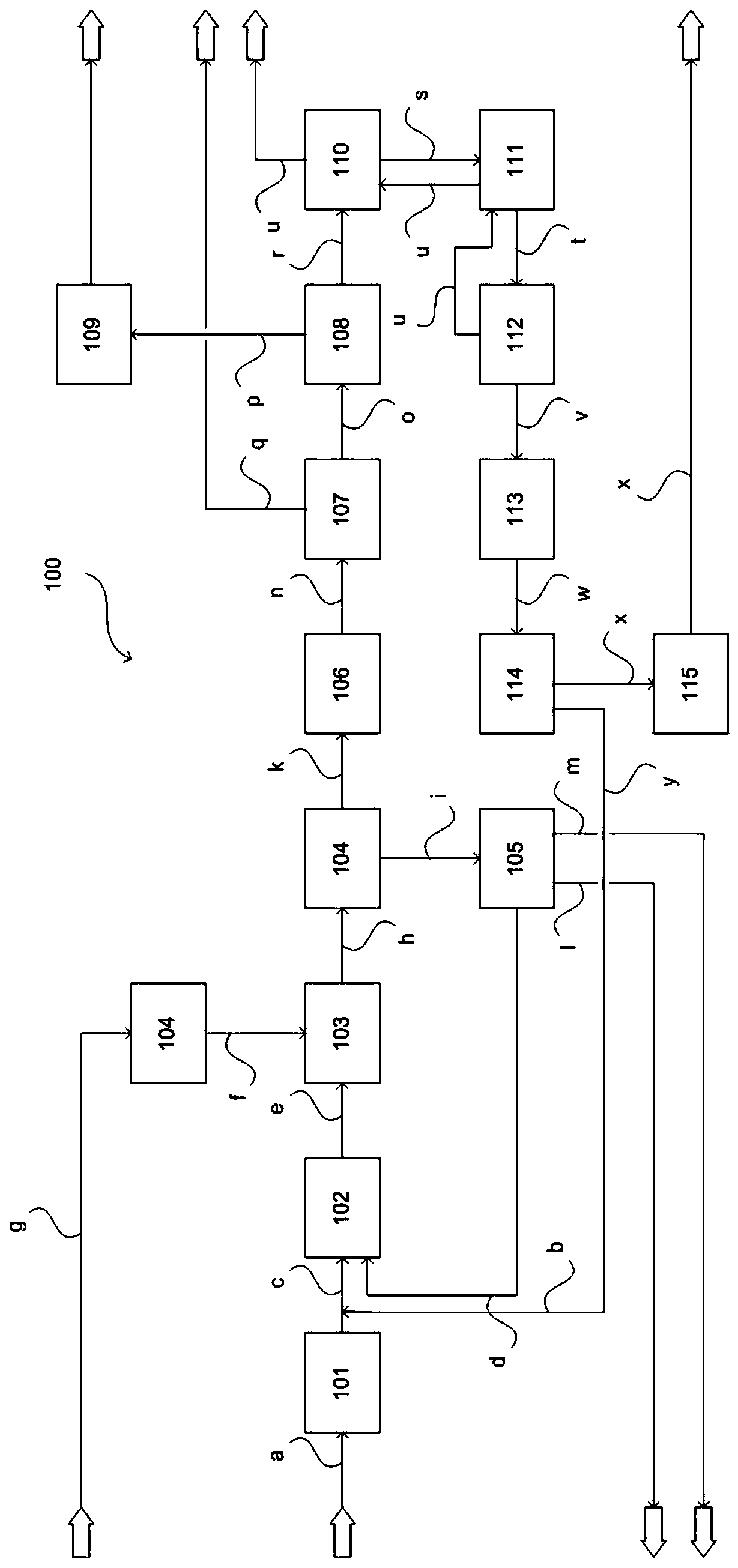

[0058] In the following figures, functionally or structurally equivalent elements are denoted by the same reference numerals, and for the sake of simplicity, the description is not repeated. When device parts are described below, statements regarding these also apply correspondingly to method steps carried out by these device parts, and vice versa.

[0059] exist figure 1 In , an apparatus for the production of olefins according to one embodiment of the present invention is shown in the form of a greatly simplified apparatus diagram and is generally referred to as 100 . Although the apparatus 100 is described below for ODH of ethane (ODH-E), as stated, the present invention is also applicable to ODH of higher hydrocarbons. In this case, the following instructions apply accordingly.

[0060] In the plant 100, the separated input in the form of stream a is supplied to a rectification unit 101 having, for example, one or more rectification columns and rectified. In the descri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com