Method using hydrophobically modified core-shell catalyst ZIF-67@SiO2 in transfer hydrogenation of cinnamaldehyde to prepare cinnamyl alcohol

A ZIF-67, core-shell catalyst technology, applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve problems such as structural instability, achieve low production cost, low price, and solve structural instability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

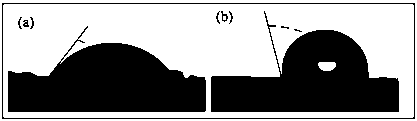

Image

Examples

Embodiment 1

[0026] Example 1 ZIF-67-@SiO 2 Used to catalyze the transfer hydrogenation reaction of cinnamaldehyde

[0027] (1) ZIF-67-@SiO 2 resolve resolution

[0028] 1.1 Preparation of ZIF-67@SiO by rapid stirring method 2

[0029] 3.4mmol Co(NO 3 ) 2 ·6H 2 O was dissolved in an appropriate amount of methanol solution, and ultrasonically dispersed for 10 minutes. Dissolve 23.8mmol 2-methylimidazole in an appropriate amount of methanol, and ultrasonically disperse for 10min. Slowly drop the prepared 2-methylimidazole solution into the prepared Co(NO 3 ) 2 ·6H 2 O solution, stirred at room temperature for 24 hours, washed by centrifugation, and washed three times with appropriate amount of DMF and methanol respectively; after repeated washing and centrifuged, the resulting precipitate was vacuum-dried at 80°C to obtain the catalyst ZIF-67. Take 0.1g ZIF-67 and dissolve it in 133.3mL methanol under ultrasonic. Then use 0.1mol / L NaOH to adjust the pH of the ZIF-67 solution to 8...

Embodiment 2

[0037] ZIF-67@SiO2 Used to catalyze cinnamaldehyde reaction cycle experiment test

[0038] The catalyst after the reaction in Example 1 was centrifuged and washed with ethanol several times, dried in vacuum at 80°C for 12 hours, and the recovered catalyst was reacted at 180°C and 1Mpa nitrogen for 18 hours, and the number of cycles was as follows:

[0039] Cycles temperature / ℃ time / h Pressure / MPa Conversion rate of cinnamyl alcohol Cinnamyl Alcohol Selectivity 1 180 18 1 98.63 93.65 2 180 18 1 98.79 93.26 3 180 18 1 97.65 94.01 4 180 18 1 97.32 94.28

[0040] It can be seen from the above table that the catalyst obtained in the present invention is applied in the reaction of cinnamaldehyde hydrogenation to cinnamyl alcohol, which is very stable and has very good cycle performance. After being recycled for 4 times, the catalytic performance does not decline, and the follow-up experimental results show that , continue t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com