In-vehicle heating machine and method

A technology for vehicles and combustion chambers, which is applied to vehicle components, heating/cooling equipment, air handling equipment, etc., which can solve the problems of inability to balance heating and battery life, avoid freezing problems, stabilize the ambient temperature, and increase the contact area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

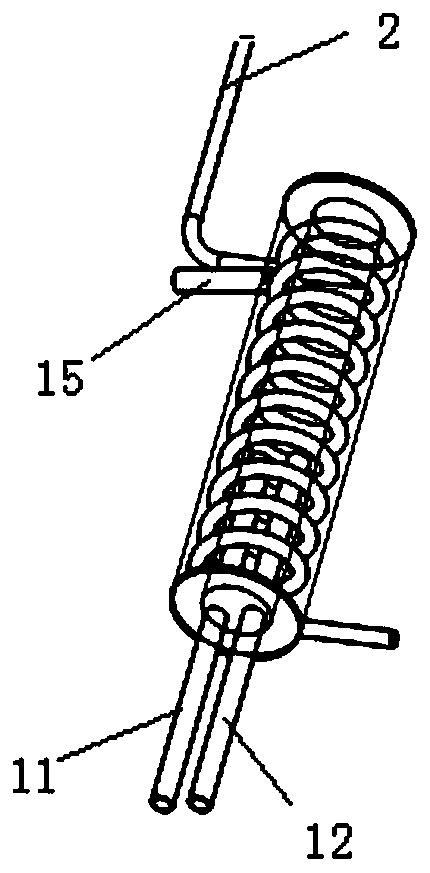

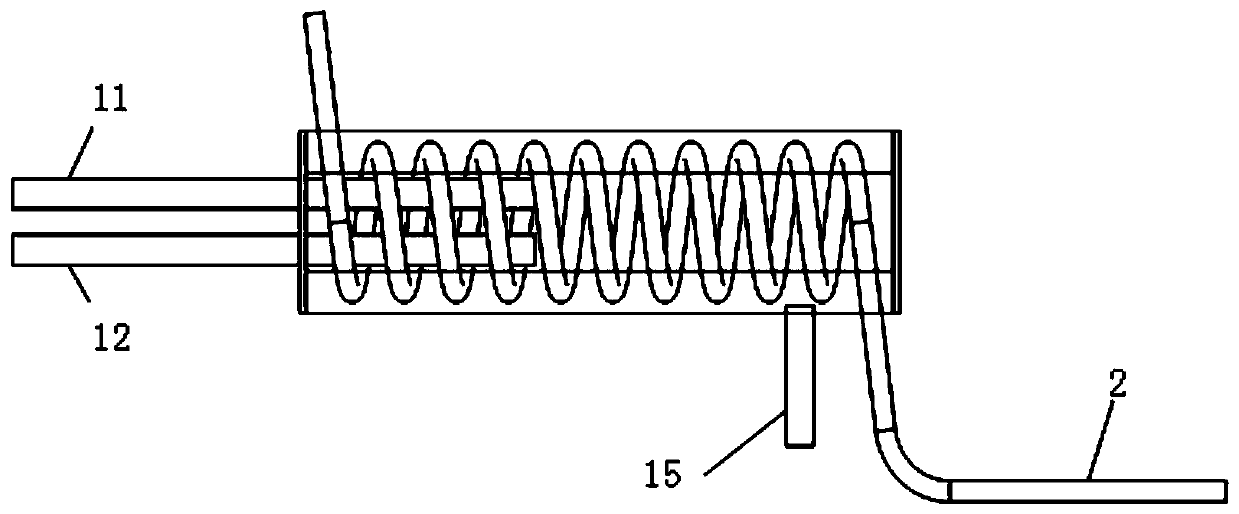

Examples

Embodiment 2

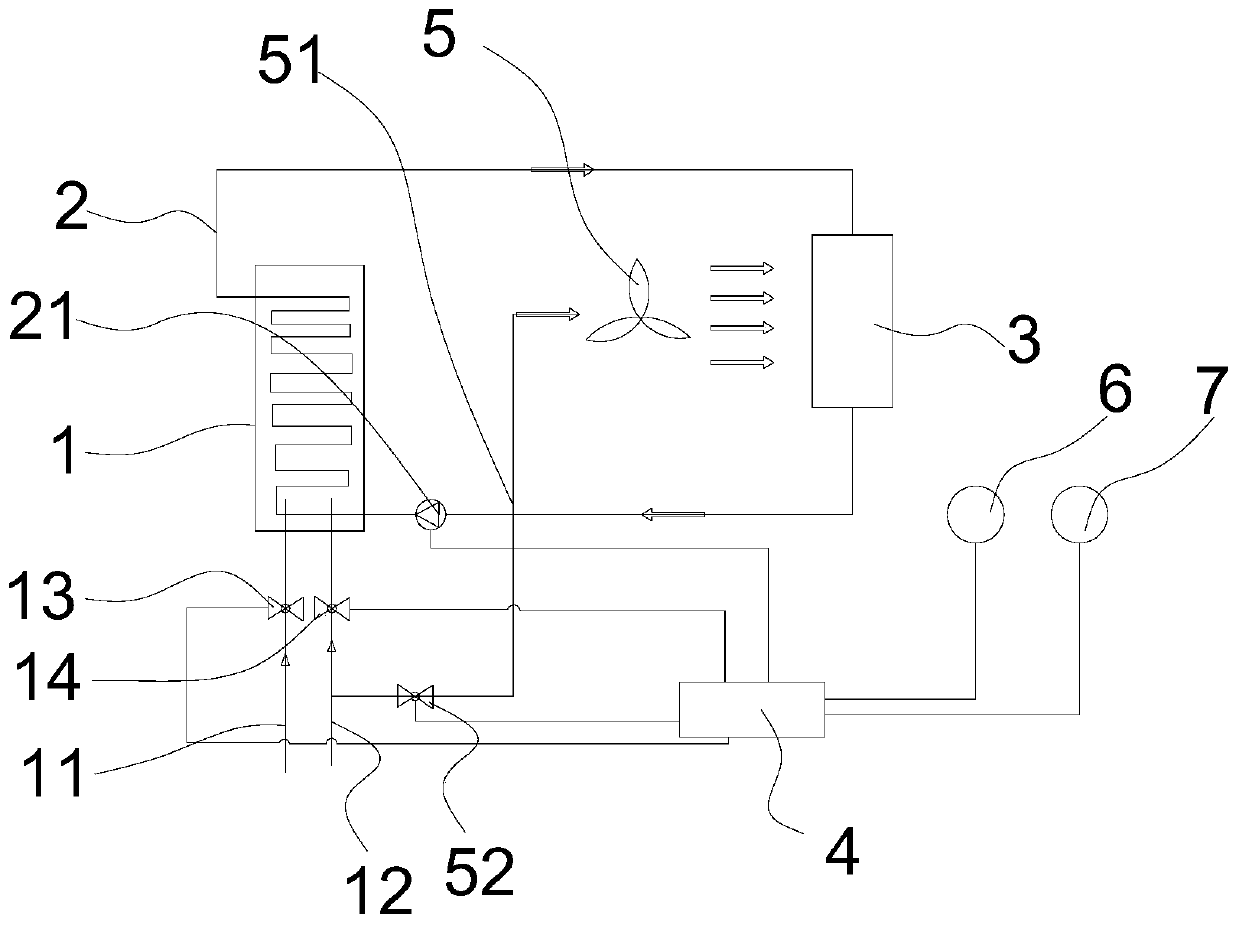

[0046] Such as figure 1 As shown, the second embodiment is based on the first embodiment, and the second embodiment also includes a blower 5 disposed on one side of the heat exchange unit 3 . The heat exchange of the heat exchange unit 3 can be accelerated by increasing the air flow through the blower 5 , the blower 5 is electrically connected to the control unit 3 , and the speed of the blower can be controlled by the control unit 3 .

[0047]Wherein, one side of the blower 5 is provided with a fresh air duct 51, and the fresh air duct 51 is connected to the air duct 11, specifically connected to the front end of the air inlet valve 13, in addition, the air duct may not be connected to the air duct 11, a new pipeline can be reintroduced from the outside of the car body, the freshness of the air in the car can be kept through the fresh air pipeline 51, and the accumulation of harmful gases can be reduced; the fresh air pipeline 51 is provided with a control valve 52, and the c...

Embodiment 3

[0049] Such as figure 1 As shown, on the basis of the first embodiment, the third embodiment further includes a gas sensor 6 , and the gas sensor 6 is electrically connected to the control unit 3 . The gas sensor 6 is mainly a gas sensor for harmful gases, which can detect harmful gases reaching a certain concentration, and feed back to the control unit 3 to open the control valve 52 on the fresh air duct 51 to increase the air flow.

[0050] The third embodiment further includes a temperature sensor 7 , and the temperature sensor 7 is electrically connected to the control unit 3 . The temperature sensor 7 can monitor the temperature in the car in real time, and control the temperature in a suitable range.

[0051] to combine Figure 6 As shown, the air inlet valve 13 and the gas inlet valve 14 are opened by the control unit 3, air and gas are respectively introduced into the air pipeline 11 and the gas pipeline 12, and the circulation pump 21, the heat exchange unit 3, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com