Heat preservation and temperature control organic waste biological drying reactor

A technology for organic waste and biological drying, applied in chemical/physical/physical-chemical stationary reactors, chemical/physical/physical-chemical processes, waste treatment, etc. and other problems, to achieve the effect of uniform heat absorption/heat dissipation, ensuring sealing and good sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

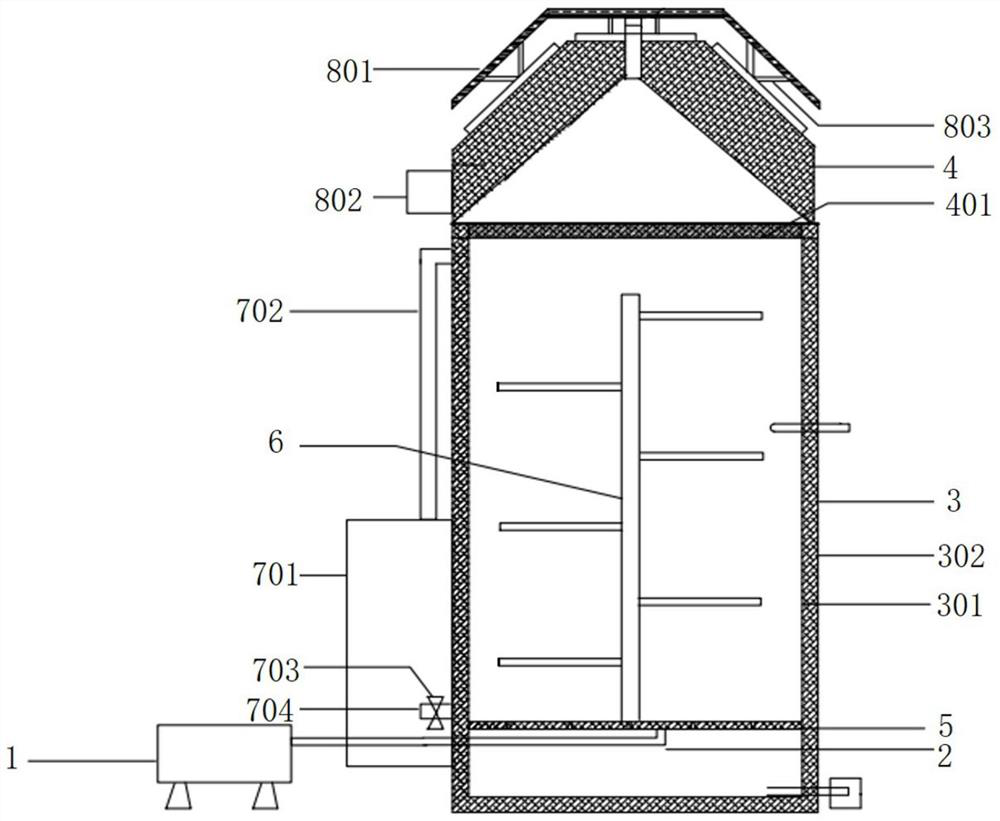

[0030] Such as figure 1 The thermal insulation and temperature control organic waste biological drying reactor shown includes a double-layer airtight chamber, a blower 1, a ventilation pipe 2, a heat storage medium circulation system and a solar power heating system;

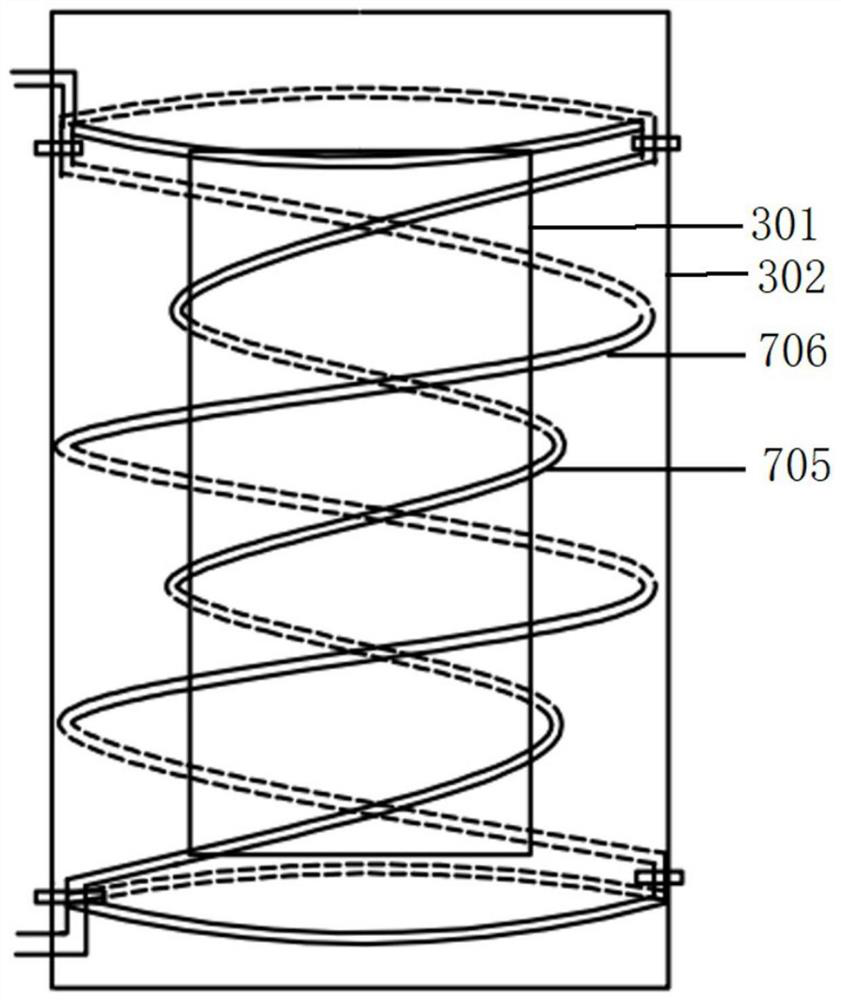

[0031] The double-layer airtight warehouse includes a warehouse body 3, a stirring mechanism 6 and a cover body 4 covered on the warehouse body 1. The warehouse body includes an inner warehouse 301 and an outer warehouse 302. The inner warehouse 301 is nested in the outer warehouse 302, and the inner warehouse 301 and the outer warehouse Between the warehouses 302 is an insulation layer. The outer compartment 302 is made of a light-transmitting material, and the light transmittance must be sufficient to make full use of solar energy, such as tempered glass, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com