High-cooling bus duct and preparation method thereof

A busway, high heat dissipation technology, applied in cooling busbar devices, fully enclosed busbar devices, etc., can solve the problems affecting the normal use of busbars, high temperature can not be discharged, casualties and property, etc., to improve the protection effect, improve impact resistance performance, The effect of improving the heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

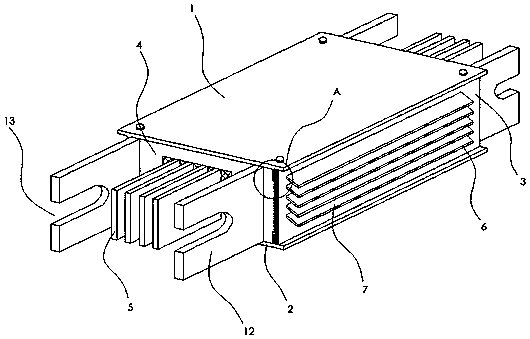

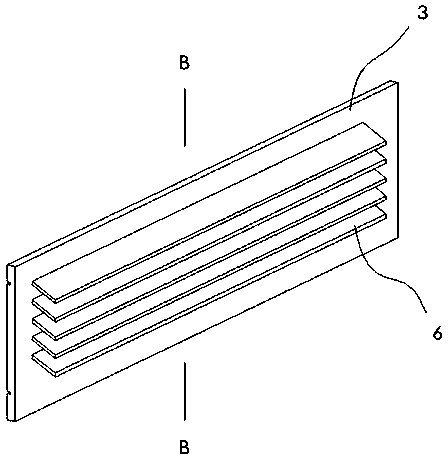

[0033] This embodiment provides a high heat dissipation busway, including an upper cover 1, a lower cover 2, a left side 3 and a right side 3, an upper cover 1, a lower cover 2, a left side 3 and a right side The board 3 encloses a wire containing chamber 4, and a busbar 5 is installed in the wire containing chamber 4. Wherein, bolt holes are provided on the upper end faces and lower end faces of the left side plate 3 and the right side plate 3, and bolt holes are also provided at the corresponding positions on the upper cover plate 1 and the lower cover plate 2, which are stabilized by bolts during installation. connect.

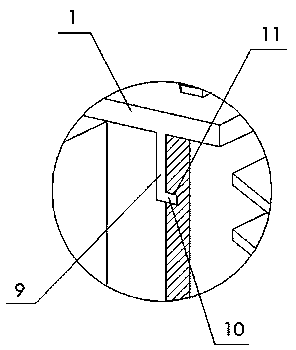

[0034] In addition, a clamping plate 9 is provided on the lower end surface of the upper cover plate 1 and the upper end surface of the lower cover plate 2, and the clamping plate 9 is L-shaped, see figure 2 , the clamping portion 10 of the clamping plate 9 faces outside the wire containing cavity 4 . Correspondingly, on the side of the left side plate 3...

Embodiment 2

[0044] This embodiment provides a high heat dissipation busway, including an upper cover 1, a lower cover 2, a left side 3 and a right side 3, an upper cover 1, a lower cover 2, a left side 3 and a right side The board 3 encloses a wire containing chamber 4, and a busbar 5 is installed in the wire containing chamber 4. Wherein, bolt holes are provided on the upper end faces and lower end faces of the left side plate 3 and the right side plate 3, and bolt holes are also provided at the corresponding positions on the upper cover plate 1 and the lower cover plate 2, which are stabilized by bolts during installation. connect.

[0045] In addition, a clamping plate 9 is provided on the lower end surface of the upper cover plate 1 and the upper end surface of the lower cover plate 2, and the clamping plate 9 is L-shaped, see figure 2 , the clamping portion 10 of the clamping plate 9 faces outside the wire containing cavity 4 . Correspondingly, on the side of the left side plate 3...

Embodiment 3

[0055] This embodiment provides a high heat dissipation busway, including an upper cover 1, a lower cover 2, a left side 3 and a right side 3, an upper cover 1, a lower cover 2, a left side 3 and a right side The board 3 encloses a wire containing chamber 4, and a busbar 5 is installed in the wire containing chamber 4. Wherein, bolt holes are provided on the upper end faces and lower end faces of the left side plate 3 and the right side plate 3, and bolt holes are also provided at the corresponding positions on the upper cover plate 1 and the lower cover plate 2, which are stabilized by bolts during installation. connect.

[0056] In addition, a clamping plate 9 is provided on the lower end surface of the upper cover plate 1 and the upper end surface of the lower cover plate 2, and the clamping plate 9 is L-shaped, see figure 2 , the clamping portion 10 of the clamping plate 9 faces outside the wire containing cavity 4 . Correspondingly, on the side of the left side plate 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com