Bus capacitor discharge control method of vehicle motor controller

A technology for motor controllers and busbar capacitors, applied in current collectors, battery circuit devices, electric vehicles, etc., can solve problems such as lack of good countermeasures, shortened life of power batteries, damage to power batteries, etc., to shorten the charge and discharge cycle, Optimized motor control, reliable discharge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

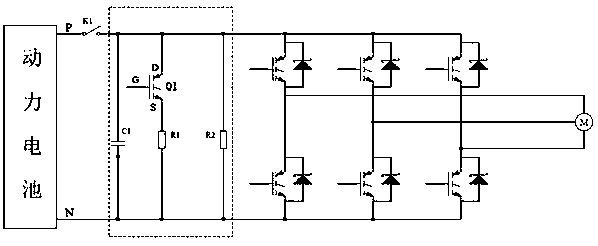

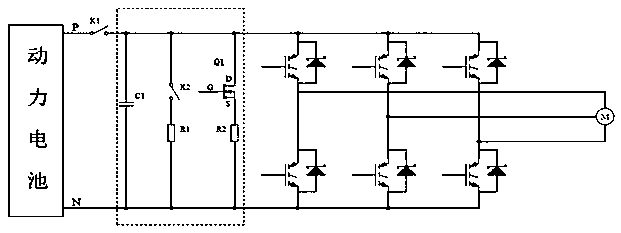

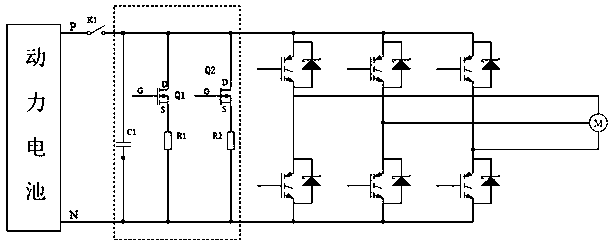

[0019] The method for controlling the discharge of the bus capacitor of the vehicle motor controller, the discharge circuit of the bus capacitor of the vehicle motor controller is composed of two active discharge circuits connected in parallel at both ends of the bus capacitor, and the active discharge circuit is composed of an active discharge resistor and a controllable discharge circuit The switches are connected in series; the controllable discharge switches of the two active discharge circuits are controlled by the processor in the motor controller MCU of the vehicle, and the control method is realized by the following steps:

[0020] 1) Detect the vehicle key switch signal. When the vehicle key switch is in the open state (parking state), control the controllable discharge switch of an active discharge circuit to close. Even if the active discharge circuit is turned on, the specified discharge time t After that (the discharge time t is determined according to the actual n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com