Agricultural punching machine

A mechanical and agricultural technology, applied in the field of agricultural planting equipment, can solve problems such as low efficiency, planting hole collapse, planting hole damage, etc., and achieve the effect of improving the drilling effect, convenient adjustment, and convenient drilling depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

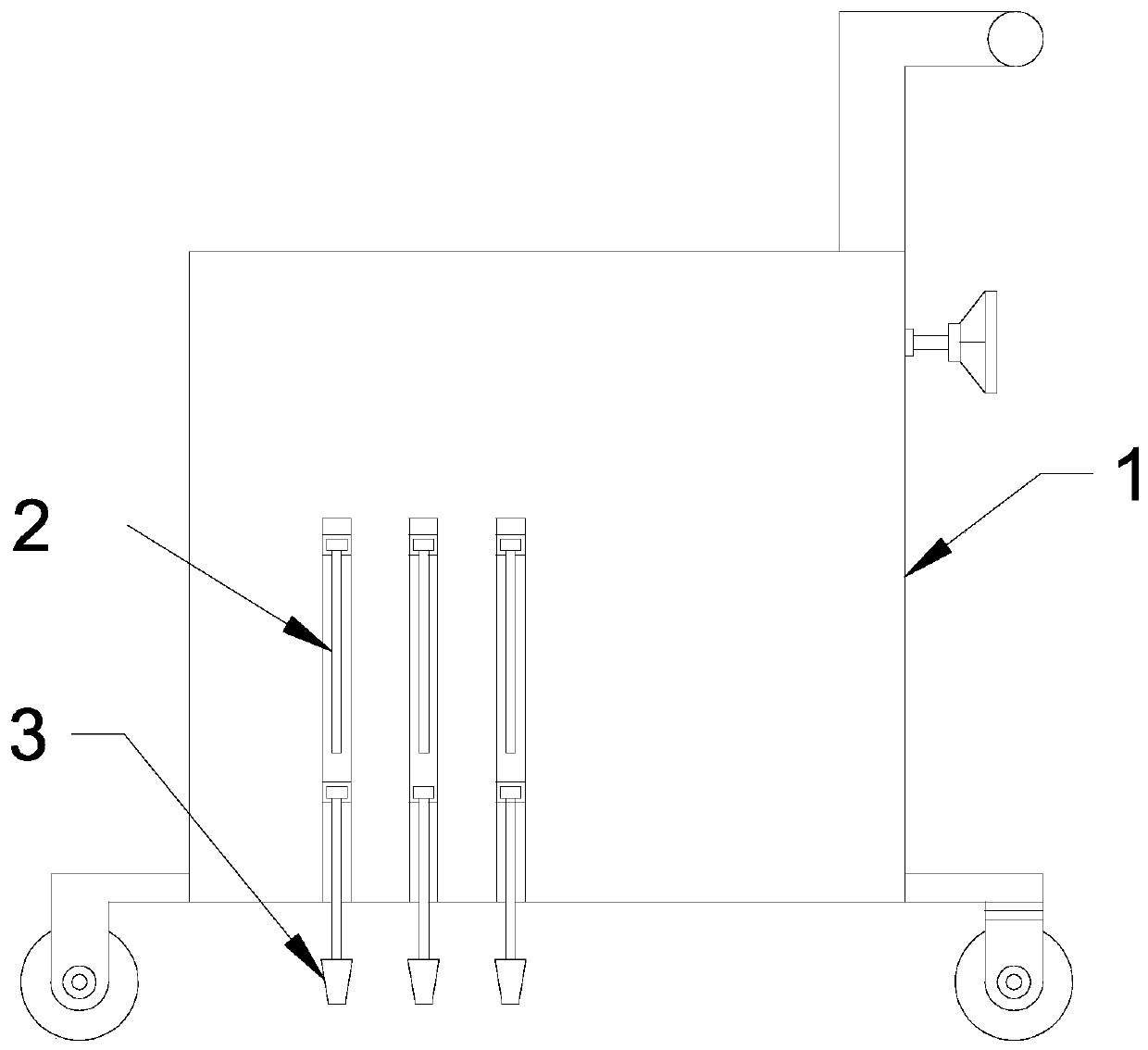

[0023] see Figure 1-6 , in an embodiment of the present invention, an agricultural punching machine includes a cart 1 and a punching rod 2; the front side of the cart 1 is provided with a punching rod 2, the punching rod 2 is a columnar rod, and the punching rod 2 Below is provided with shaping cylinder 3, and shaping cylinder 3 is the conical cylinder of upper and lower end openings, and the opening diameter of shaping cylinder 3 lower ends is larger than the diameter of punching rod 2 by 1 millimeter; The center of circle of the shaped tube 3 is located in the same vertical line, the punching rod 2 and the shaping tube 3 are respectively connected with a telescopic frame mechanism, and the telescopic frame mechanism drives the punching rod 2 and the shaping tube 3 to move toward each other or move backwards. Yes, when the punching rod 2 is punching, the punching rod 2 and the shaping cylinder 3 move toward each other, and the punching rod 2 passes through the shaping cylind...

Embodiment 2

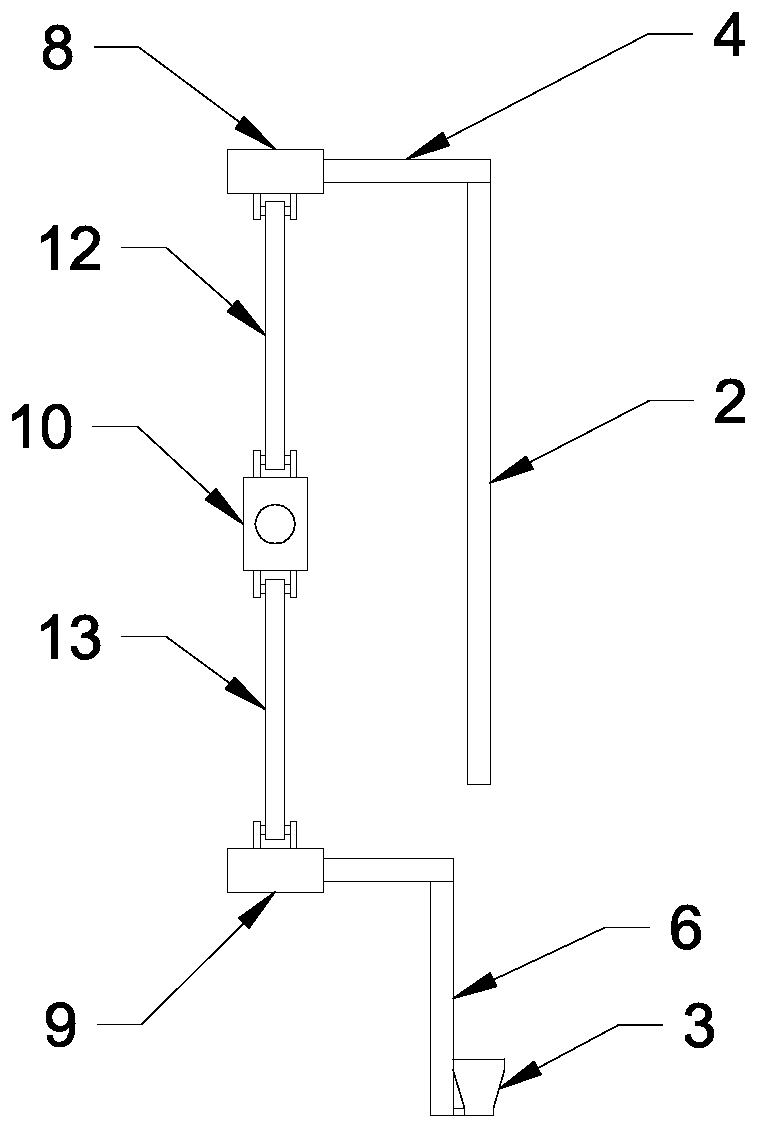

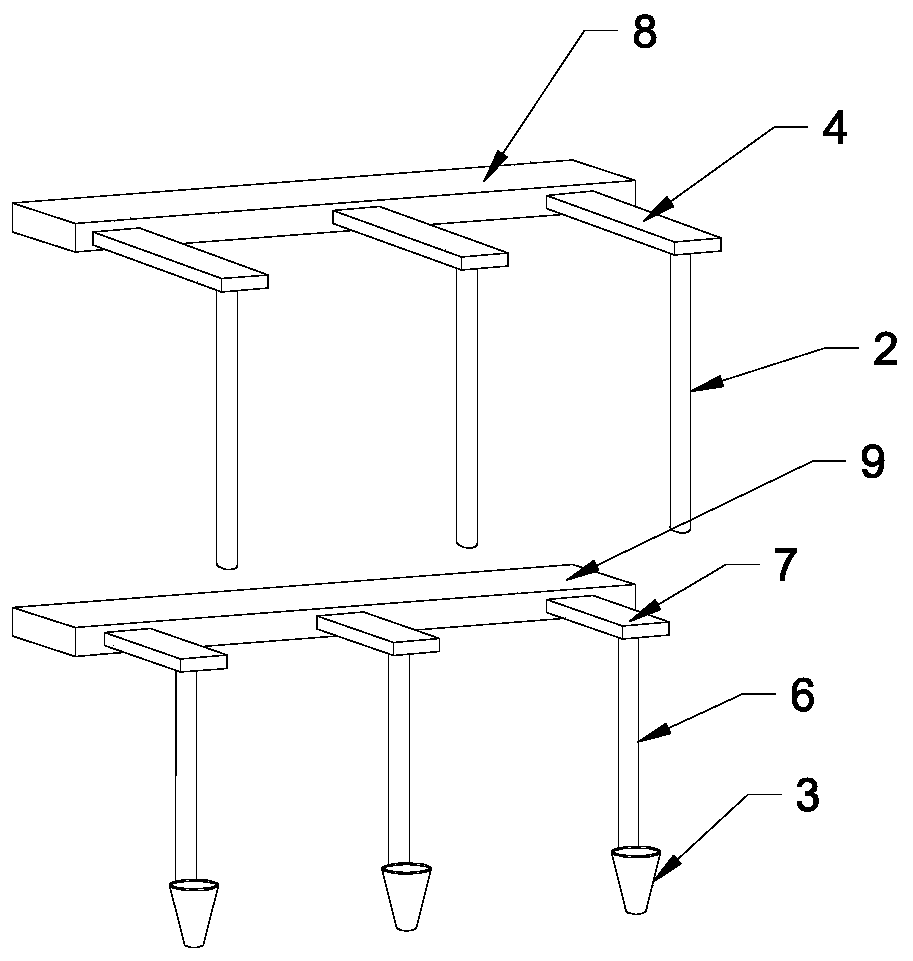

[0025] The difference between this embodiment and Embodiment 1 is that the telescopic frame mechanism includes an upper moving plate 8 and a lower moving plate 9 arranged symmetrically up and down, and the punching rod 2 is fixedly connected with the upper moving plate 8 through the upper extending plate 4 , plastic The shaped cylinder 3 is connected with a lower extension plate 7 through a vertical rod 6, and the lower extension plate 7 is fixedly connected with the lower moving plate 9; a moving block 10 is arranged between the upper moving plate 8 and the lower moving plate 9, and the moving block 10 is connected with the upper moving plate 8 through the upper connecting rod 12 arranged symmetrically, and the upper connecting rod 12 is respectively hinged with the moving block 10 and the upper moving plate 8, and the moving block 10 is connected with the lower moving plate 9 through the lower connecting rod 13, and the lower connecting rod 13 are respectively hinged with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com