Weariness-resistant noodles containing modified starch and making method of weariness-resistant noodles containing modified starch

A modified starch, anti-fatigue technology, applied in the functions of food ingredients, food ingredients as taste modifiers, food science and other directions, can solve the problems of less anti-fatigue ingredients, taste, cooking resistance and anti-fatigue efficacy to be studied, etc. Achieve the effects of low gelatinization temperature, simple and easy preparation method and good chewiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

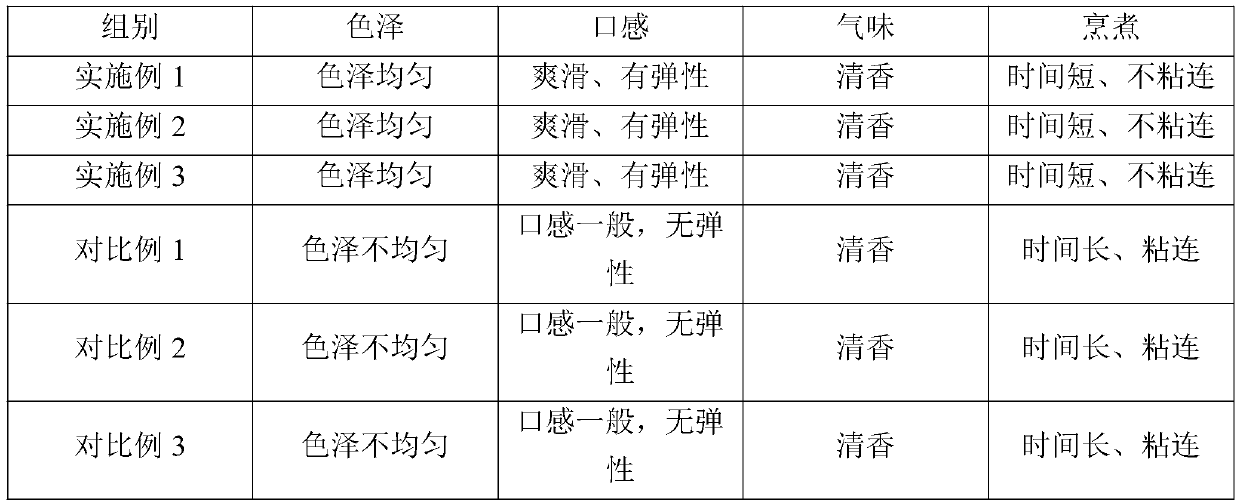

Examples

Embodiment 1

[0035] An anti-fatigue noodle containing modified starch includes the following raw materials in parts by weight: 100 parts of wheat flour, 10 parts of yam powder, 10 parts of walnut powder, 15 parts of modified starch, 5 parts of fungus extract and 70 parts of deionized water.

[0036] The modified starch is prepared by mixing corn starch and tapioca starch at a mass ratio of 3:1, and modifying them; the fungus extract is made of Stropharia rugosa extract, Chaga extract, and black truffle extract in accordance with the quality The ratio is 3:2:1.

[0037] The method for preparing the modified starch is: mixing corn starch and tapioca starch in proportions to obtain a mixed powder, using deionized water to prepare an emulsion with a concentration of 45-55%, adjusting the pH of the emulsion to 9-11, and then adding and mixing Powder weight 1-5% sodium trimetaphosphate, heat to 35-45°C and keep it for 1-3h, reduce the temperature to 20-30°C, add 0.5-1.5% acetic anhydride of mixed pow...

Embodiment 2

[0044] An anti-fatigue noodle containing modified starch comprises the following raw materials in parts by weight: 80 parts of wheat flour, 5 parts of yam powder, 5 parts of walnut powder, 10 parts of modified starch, 1 part of fungus extract and 40 parts of deionized water.

[0045] The modified starch is prepared by mixing corn starch and tapioca starch with a mass ratio of 2:1, and modifying the preparation; the fungus extract is made of Stropharia rugosa extract, Chaga extract and black truffle extract in accordance with the quality The ratio is 2:1:1.

[0046] The method for preparing the modified starch is: mixing corn starch and tapioca starch in proportions to obtain a mixed powder, using deionized water to prepare an emulsion with a concentration of 45-55%, adjusting the pH of the emulsion to 9-11, and then adding and mixing Powder weight 1-5% sodium trimetaphosphate, heat to 35-45°C and keep it for 1-3h, reduce the temperature to 20-30°C, add 0.5-1.5% acetic anhydride of ...

Embodiment 3

[0053] An anti-fatigue noodle containing modified starch comprises the following raw materials in parts by weight: 120 parts of wheat flour, 15 parts of yam powder, 15 parts of walnut powder, 20 parts of modified starch, 10 parts of fungus extract and 100 parts of deionized water.

[0054] The modified starch is prepared by mixing corn starch and tapioca starch at a mass ratio of 4:1, and modifying the preparation; the fungus extract is made of Stropharia rugosa extract, Chaga extract and black truffle extract in accordance with the quality The ratio is 4:3:1.

[0055] The method for preparing the modified starch is: mixing corn starch and tapioca starch in proportions to obtain a mixed powder, using deionized water to prepare an emulsion with a concentration of 45-55%, adjusting the pH of the emulsion to 9-11, and then adding and mixing Powder weight 1-5% sodium trimetaphosphate, heat to 35-45°C and keep it for 1-3h, reduce the temperature to 20-30°C, add 0.5-1.5% acetic anhydride...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com