Corrugated floor slab and preparation method thereof

A corrugated floor and corrugated board technology, applied in building materials, building components, buildings, etc., can solve the problems of suboptimal state, heavy floor weight, high construction cost, etc., to save raw material consumption, reduce weight, and maintain strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

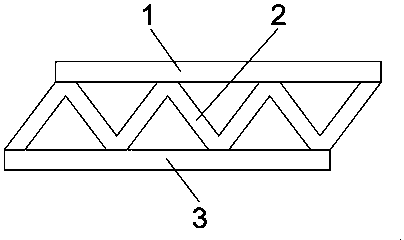

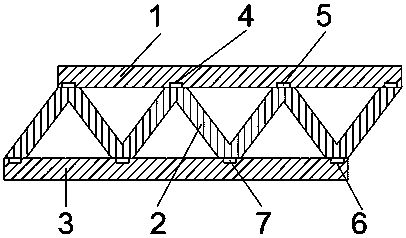

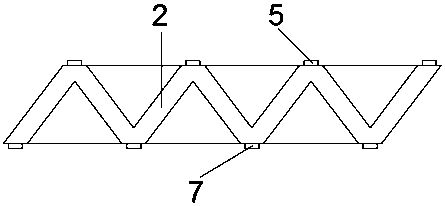

[0034] Such as Figure 1-6 The corrugated floor board shown includes an upper panel 1 and a lower panel 3. The upper panel 1 is connected to the lower panel 3 through a corrugated structure, and the upper panel 1 and the lower panel 3 are connected to form a corrugated floor board by using a corrugated structure, which greatly reduces the cost of raw materials. The dosage and the overall weight, without affecting the strength of the floor slab, solve the shortcomings of the inconspicuous weight reduction of the current floor slab adopting the method of leaving a hole in the middle and recessing both sides. Specifically, the corrugated structure includes corrugated board 2, corrugated board 2 The first tenon 5 and the second tenon 7 are fixedly installed at the upper and lower ends respectively, preferably the first tenon 5 and the second tenon 7 are integrally formed with the corrugated board 2, not only the structure is more stable, but also the preparation is more convenient ...

Embodiment 2

[0040] Such as Figure 7-11 The corrugated floor board shown includes an upper panel 1 and a lower panel 3. The upper panel 1 is connected to the lower panel 3 through a corrugated structure, and the upper panel 1 and the lower panel 3 are connected to form a corrugated floor board by using a corrugated structure, which greatly reduces the cost of raw materials. The dosage and the overall weight, without affecting the strength of the floor slab, solve the shortcomings of the inconspicuous weight reduction of the current floor slab adopting the method of leaving holes in the middle and recessing on both sides. 8. The upper and lower ends of the corrugated board 2 are respectively fixed with a first tenon 5 and a second tenon 7, and the bottom of the upper panel 1 is provided with a first tenon 4 matching the first tenon 5, so The upper surface of the lower panel 3 is provided with a second card slot 6 matching with the second tenon 7; the partition plate 8 is provided with a th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com