A remote gearbox fault monitoring system based on labview

A fault monitoring and gearbox technology, applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve the problems of inconvenient, cumbersome, and difficult to distinguish faults in gear monitoring, and achieve remote status monitoring, fault detection, etc. Reasonable analysis and the effect of fault diagnosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

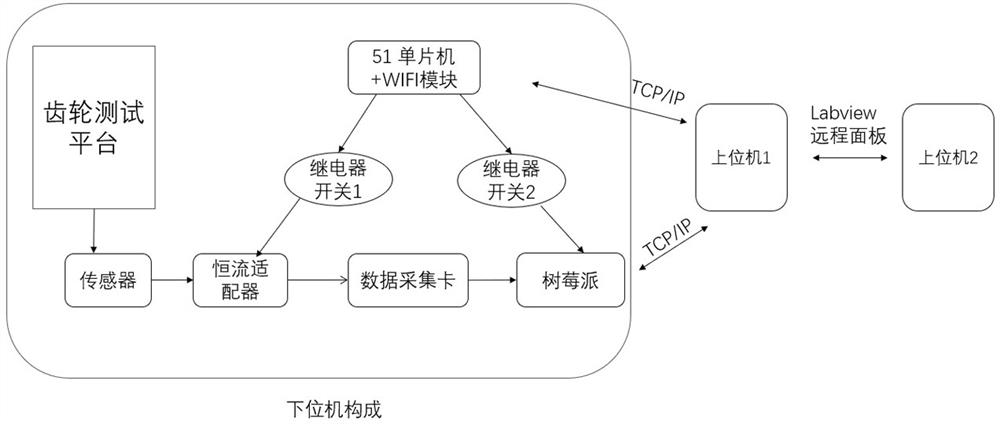

[0046] The technical solution of the present invention will be specifically described below in conjunction with the accompanying drawings.

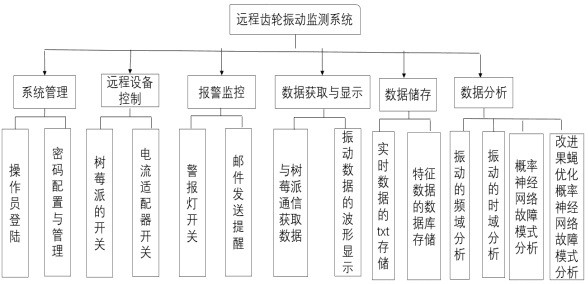

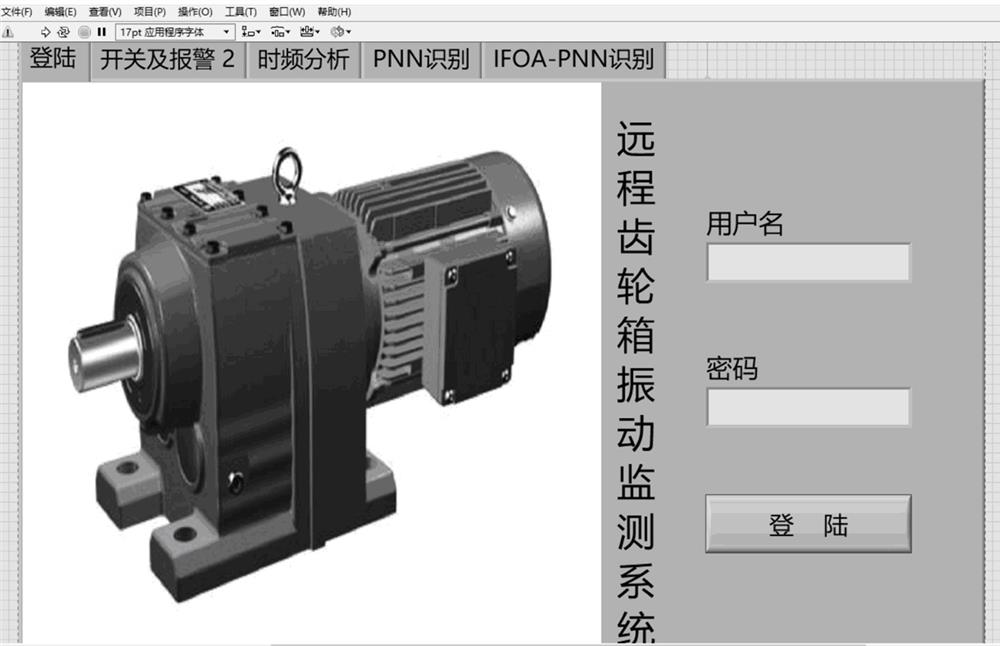

[0047]The invention provides a remote gearbox fault monitoring system based on LabVIEW, comprising a vibration sensor, a constant current adapter, a data acquisition card, a raspberry pie, a single-chip microcomputer, a WIFI module, a relay, and an upper computer unit;

[0048] The vibration sensor is adsorbed on the surface of the gearbox and close to the top of the bearing end cover;

[0049] The constant current adapter is connected with the vibration sensor for adjusting the vibration signal measured by the vibration sensor;

[0050] The data acquisition card is connected with the constant current adapter, and is used to transmit the vibration signal data output by the constant current adapter to the raspberry pie;

[0051] The driver of data acquisition card and related setting program are stored in the described raspberry group, to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com