Transfer printing film adhesive layer coating device

A coating device and adhesive layer technology, applied in spraying devices, liquid spraying devices, spray booths, etc., can solve the problems of lower product yield, substrate contamination, gluing, unevenness, etc., to avoid glue splashing, Ensure the effect of gluing and air quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

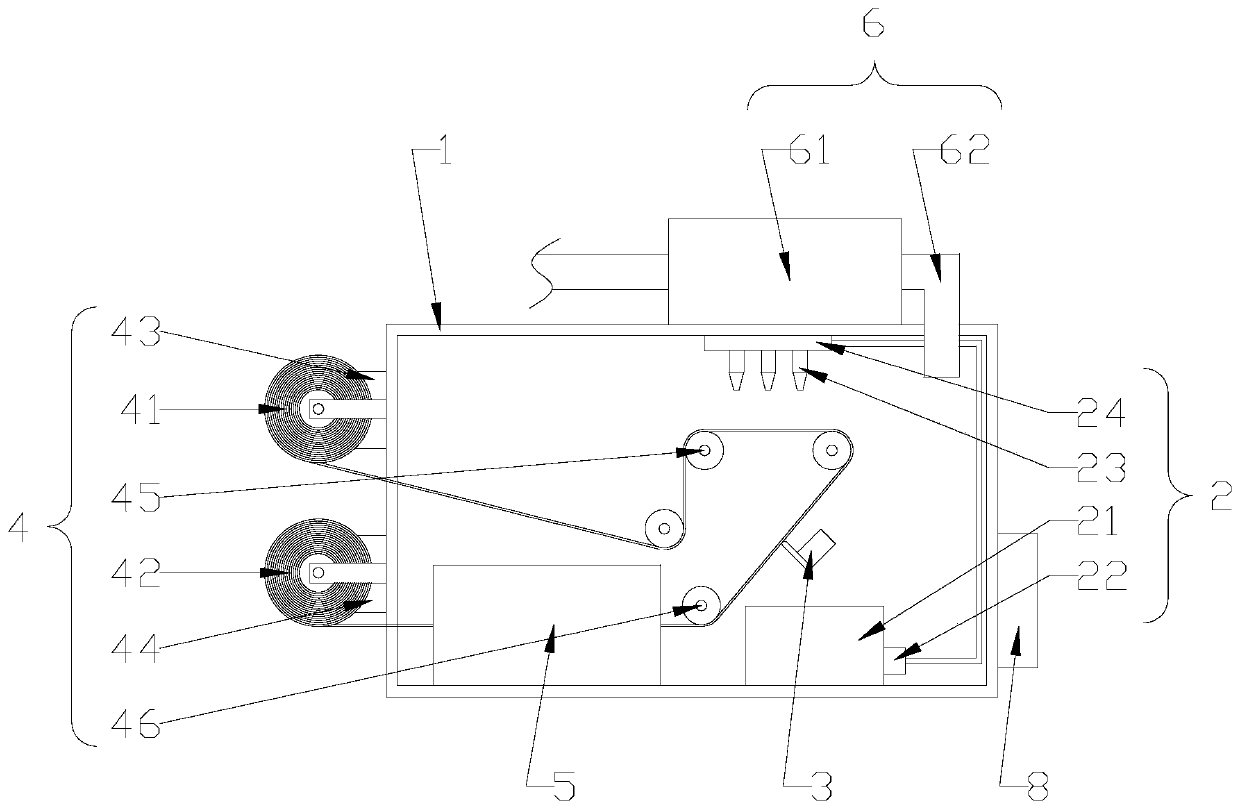

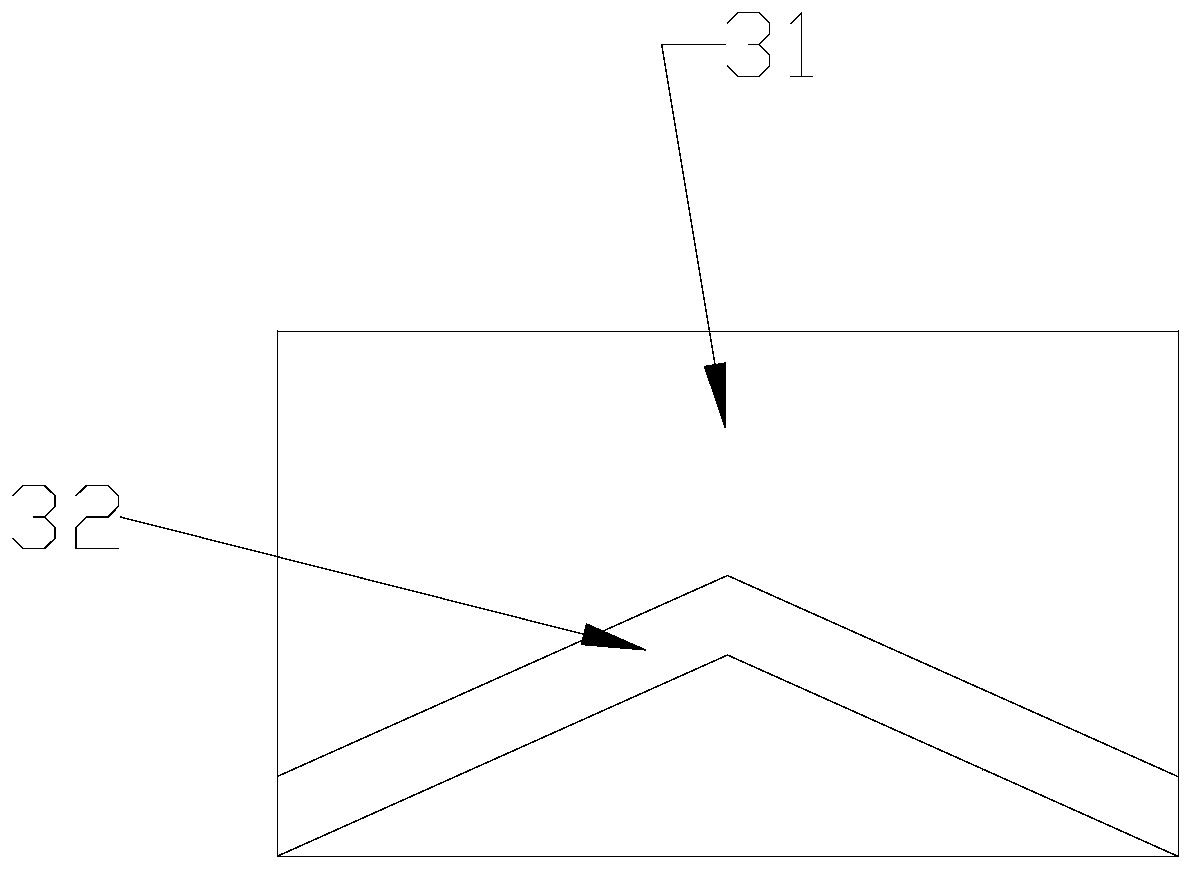

[0020] refer to figure 1 and figure 2 , a transfer film adhesive layer coating device of the present invention includes an outer casing 1, a glue spraying unit 2, a scraper 3, a conveying unit 4, an oven 5, a deodorizing unit 6 and a control unit 8, and the conveying unit 4 includes The feed roller 41 and the discharge roller 42 fixed on the outside of the outer casing 1 by the support frame, the feed roller 41 and the discharge roller 42 are wound around the two ends of the substrate to be coated and pass through the first motor 43 and the second motor respectively. Two motors 44 are driven to rotate, and the central section of the substrate to be coated extends into the housing 1 and is guided by several first guide rollers 45 to form a coating plane. Two guide rollers 46, the rear section of the substrate to be coated is guided by the second guide roller 46 to form a scraping slope and then passes through the oven 5 and finally guides back to the discharge roller 42, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com