Hard die riser used for gravity casting pouring and casting method thereof

A gravity casting and riser technology, which is applied to casting molding equipment, casting molds, and casting mold components, can solve problems affecting work efficiency, wasting manpower, and impurities, so as to reduce feeding range, increase pouring effect, and increase The effect of cooling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In the following description, numerous specific details are given in order to provide a more thorough understanding of the present invention. It will be apparent, however, to one skilled in the art that the present invention may be practiced without one or more of these details. In other examples, some technical features known in the art are not described in order to avoid confusion with the present invention.

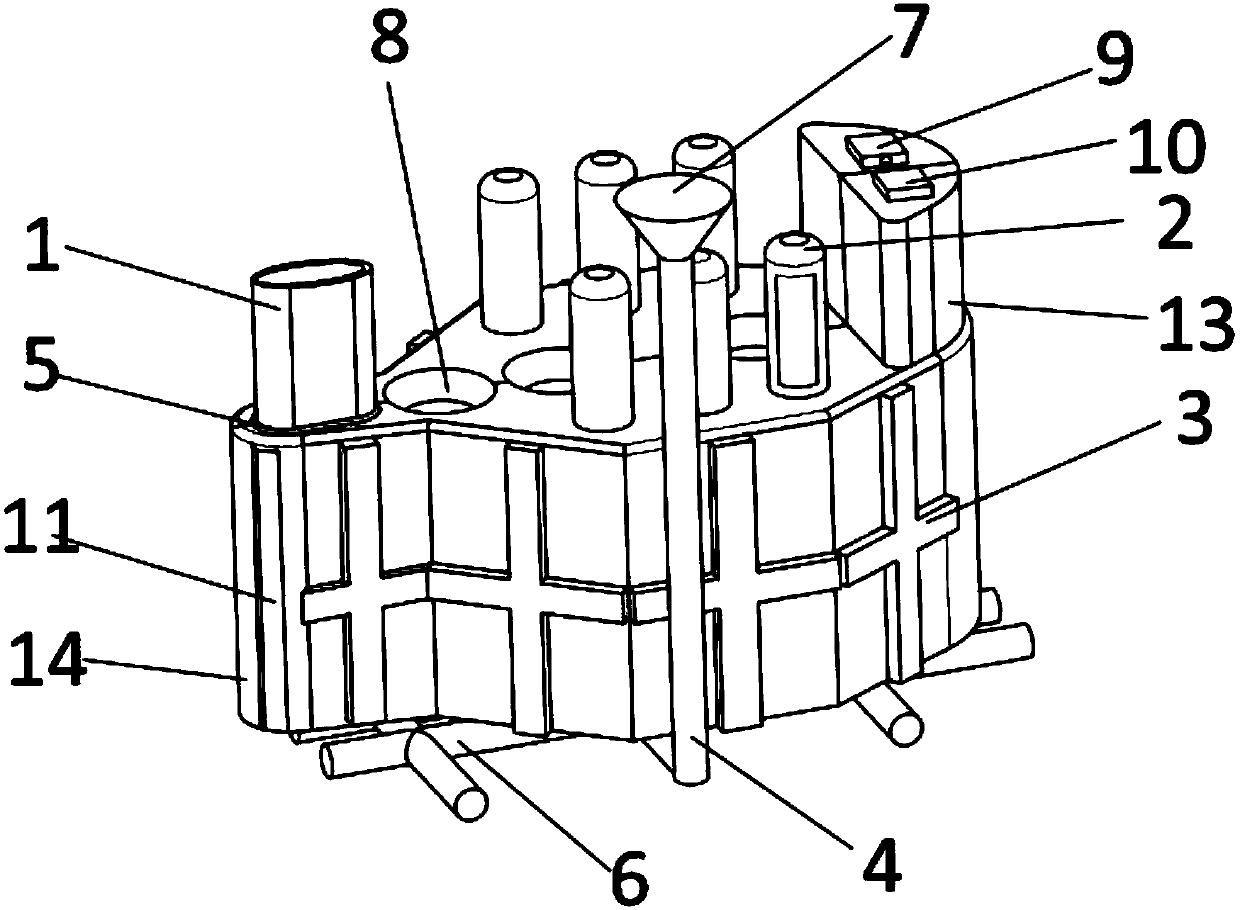

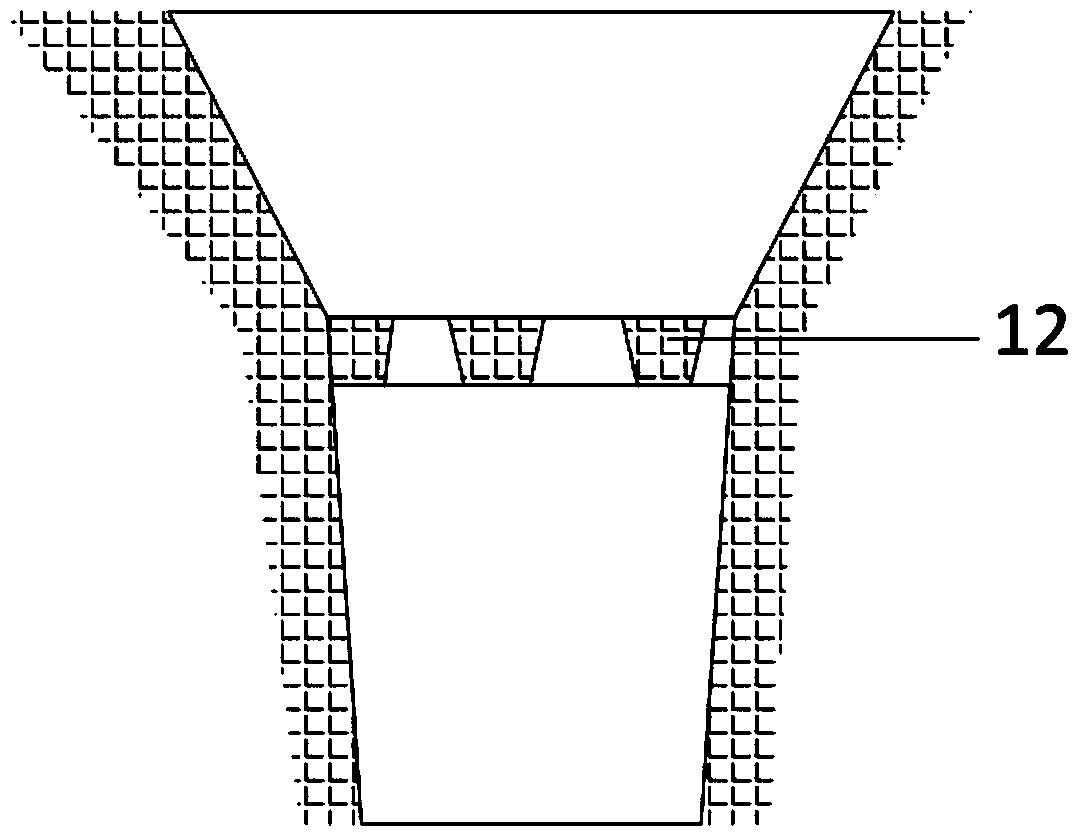

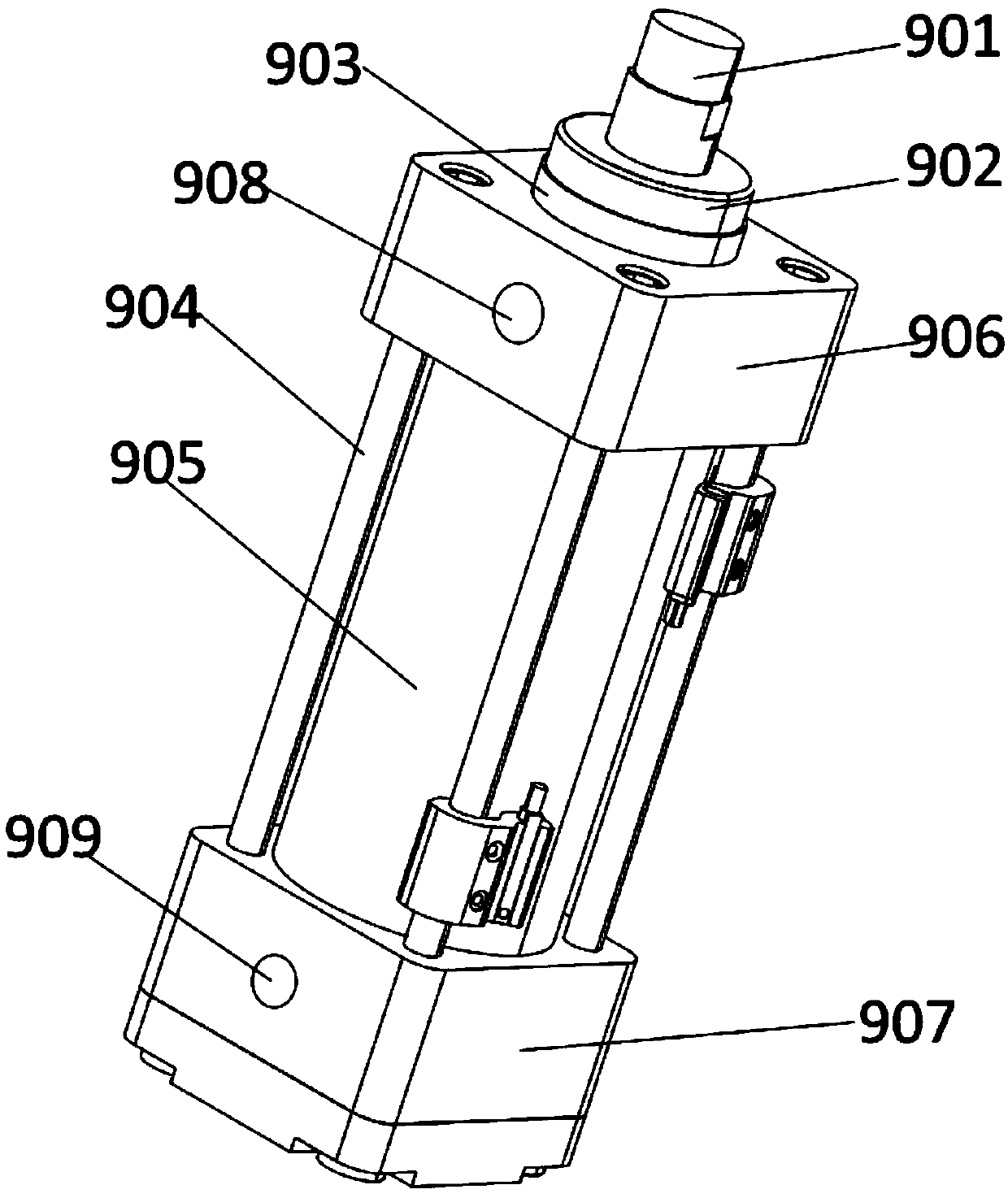

[0035] A hard mold riser for gravity casting and casting method thereof, comprising: discharge port 1, riser sleeve 2, cross chiller 3, sprue 4, material neck 5, runner 6, sprue Cup 7, exhaust hole 8, cylinder 9, pad 10, vertical cooling iron 11, filter screen 12, table top 13, housing 14, piston assembly 901, guide part 902, fixing part 903, support rod 904, storage chamber 905, upper fixed frame 906, lower fixed frame 907, air outlet 908, air inlet 909.

[0036] Wherein, the side wall of the housing 14 is provided with a cross chill 3, and the cross chill 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com