Welding device for U-shaped or V-shaped workpiece

A welding device and workpiece technology, applied in welding equipment, manufacturing tools, resistance welding equipment, etc., can solve the problems of long processing time, high operator skill requirements, and inability to realize resistance spot welding process, and achieve reliable welding and electrical connection. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

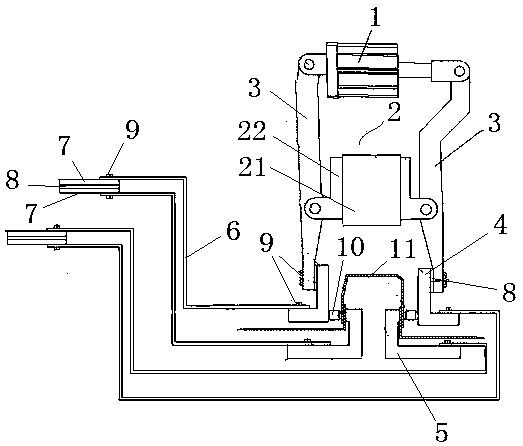

[0018] This embodiment proposes a welding device, which can be used for resistance welding of U-shaped or V-shaped workpieces such as the taillight mounting plate of the body-in-white.

[0019] like figure 1 As shown, the welding device of this embodiment includes a pressing arm mechanism and a support member, and the pressing arm mechanism includes a cylinder 1, a connecting seat 2, and two pressing arms 3 respectively located on both sides of the cylinder 1 and the connecting seat 2, wherein the first pressing arm The connecting end of the arm 3 is hinged to the cylinder body of the cylinder 1, the middle part of the first pressing arm 3 is hinged to the connecting seat 2; the connecting end of the second pressing arm 3 is hinged to the end of the piston rod of the cylinder 1, and the middle part of the second pressing arm 3 It is hinged with the connecting base 2; the free ends of the two pressing arms 3 are equipped with copper connecting blocks 4.

[0020] When the pisto...

Embodiment 2

[0030] The difference from Embodiment 1 is that in this embodiment, the supporting member also includes a supporting frame, on which a slide rail with a T-shaped cross-section is provided, and two supporting blocks 5 are provided with grooves for matching with the sliding rail , the support block 5 is movably connected with the support frame through the cooperation of the slide rail and the groove body; the two support blocks 5 are connected by elastic members. The above-mentioned slide rail can limit the moving direction of the support block 5, and prevent the support block 5 from falling from the support frame, which improves the safety, and the support block 5 can be attached to the surface of the workpiece 11 to be welded by the elastic member, ensuring that the support block 5 5. The electrical connection with the workpiece 11 to be welded is good, making the welding more reliable.

[0031] In addition, the seat body 21 of the connection seat 2 is fixedly connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com