Intelligent welding device for the noodle bar hanger used in the production line of health-care noodles

A welding device and production line technology, applied in welding equipment, auxiliary devices, auxiliary welding equipment, etc., can solve the problems of low welding work efficiency, inconsistent welding point positions, and inability to guarantee shape tolerances, etc. The effect of unified location and guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

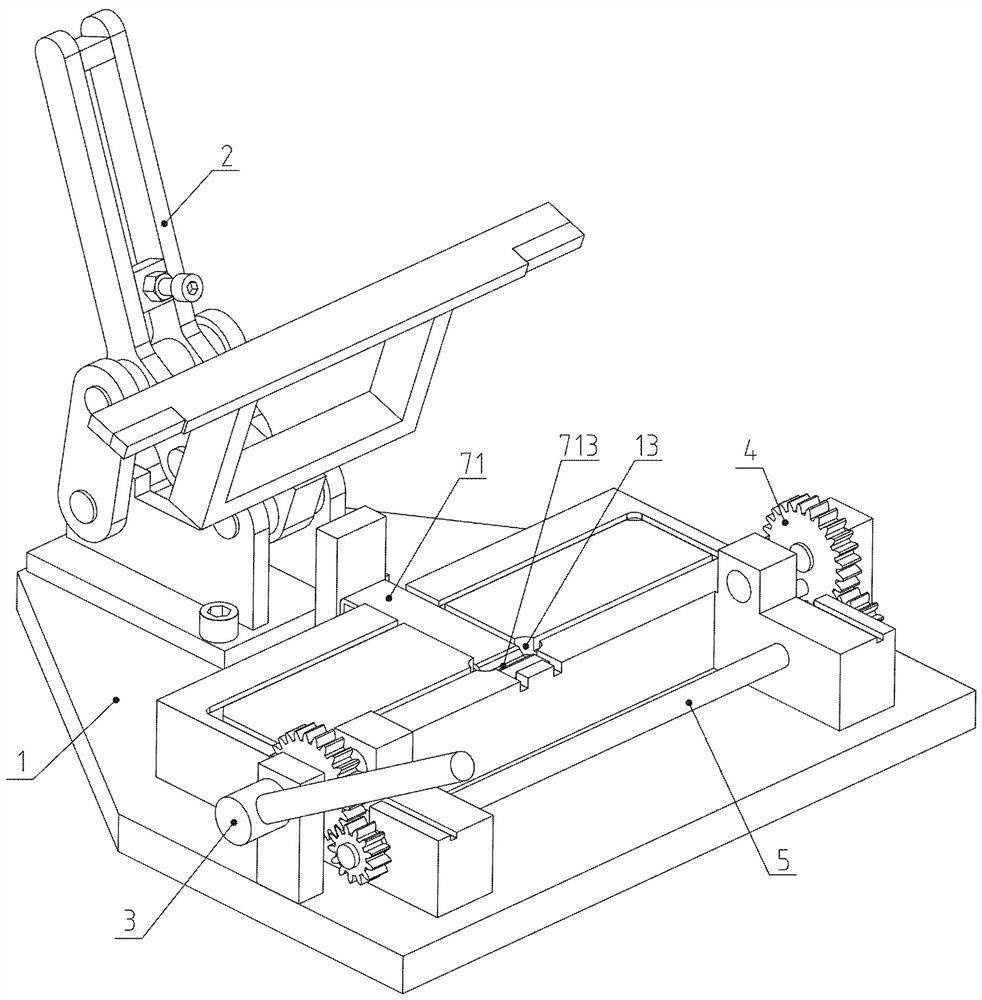

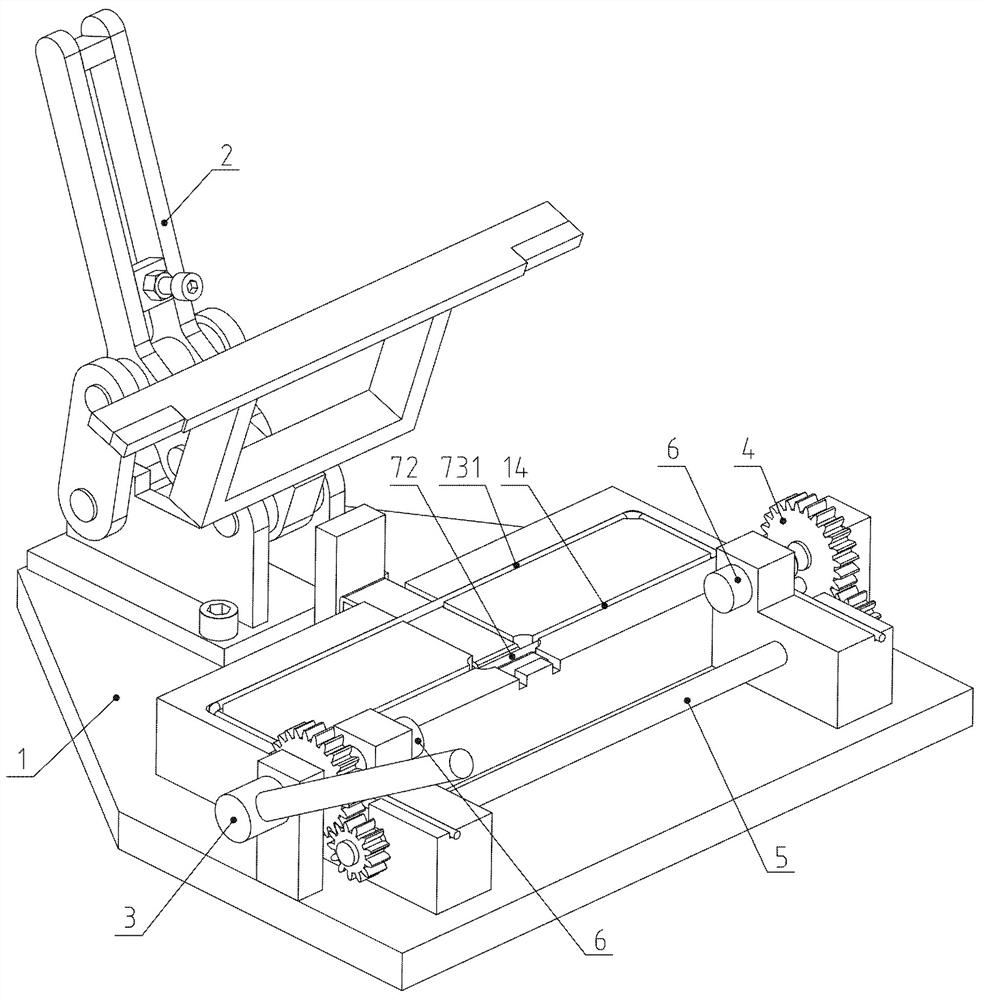

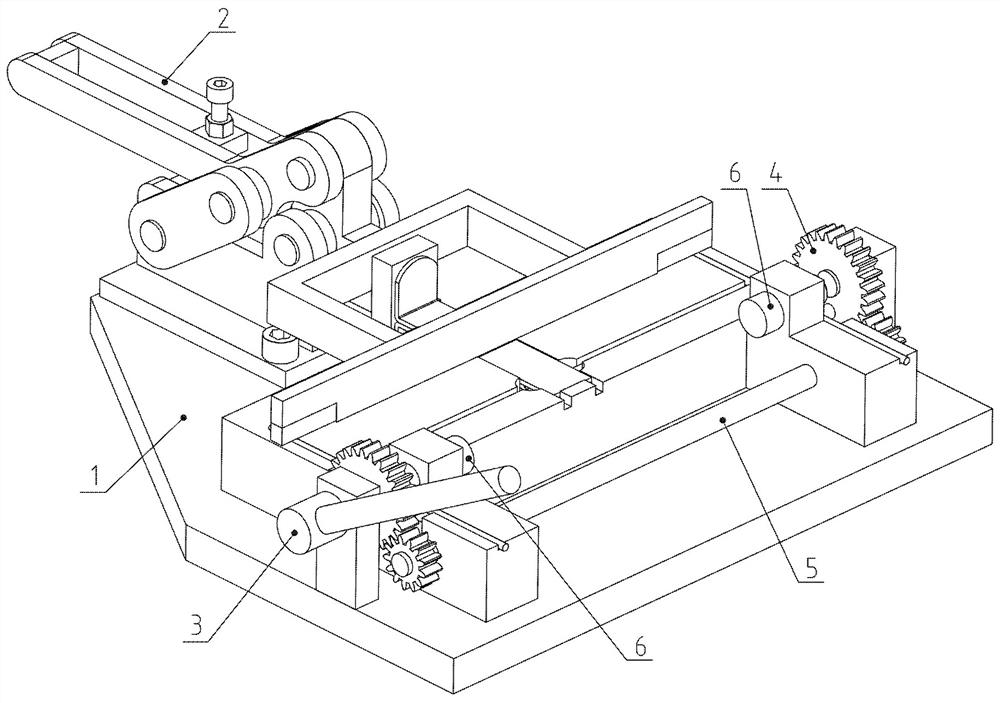

[0064] Example: see Figure 1 to Figure 18 .

[0065] An intelligent welding device for a noodle bar hanger for a production line of health-care noodles, including a welding platform 1, a quick clamp 2, a wrench gear assembly 3, a passive gear assembly 4, an intermediate gear assembly 5, a pin 6, an intelligent robot and a robot Use a spot welding machine; the base of the intelligent robot is fixed on the frame, and the robot is fixed at the end of the arm of the intelligent robot with a spot welding machine;

[0066] The welding platform 1 is provided with a horizontal edge positioning plate 11, and the horizontal edge positioning plate 11 has a vertical surface facing forward, and the vertical surface is used to locate the horizontal edge 712 of the lower curved plate and the horizontal edge 742 of the upper curved plate; the welding platform 1 There are vertical edge positioning grooves 12 in the front and rear horizontal directions, and the vertical edge positioning groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com