Double-component cement-based super-flexible self-leveling cement

A super-flexible and self-leveling technology, applied in the cement field, can solve problems such as hollowing and easy cracking, achieve super flexibility and adhesion, prevent bulges, and increase the bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

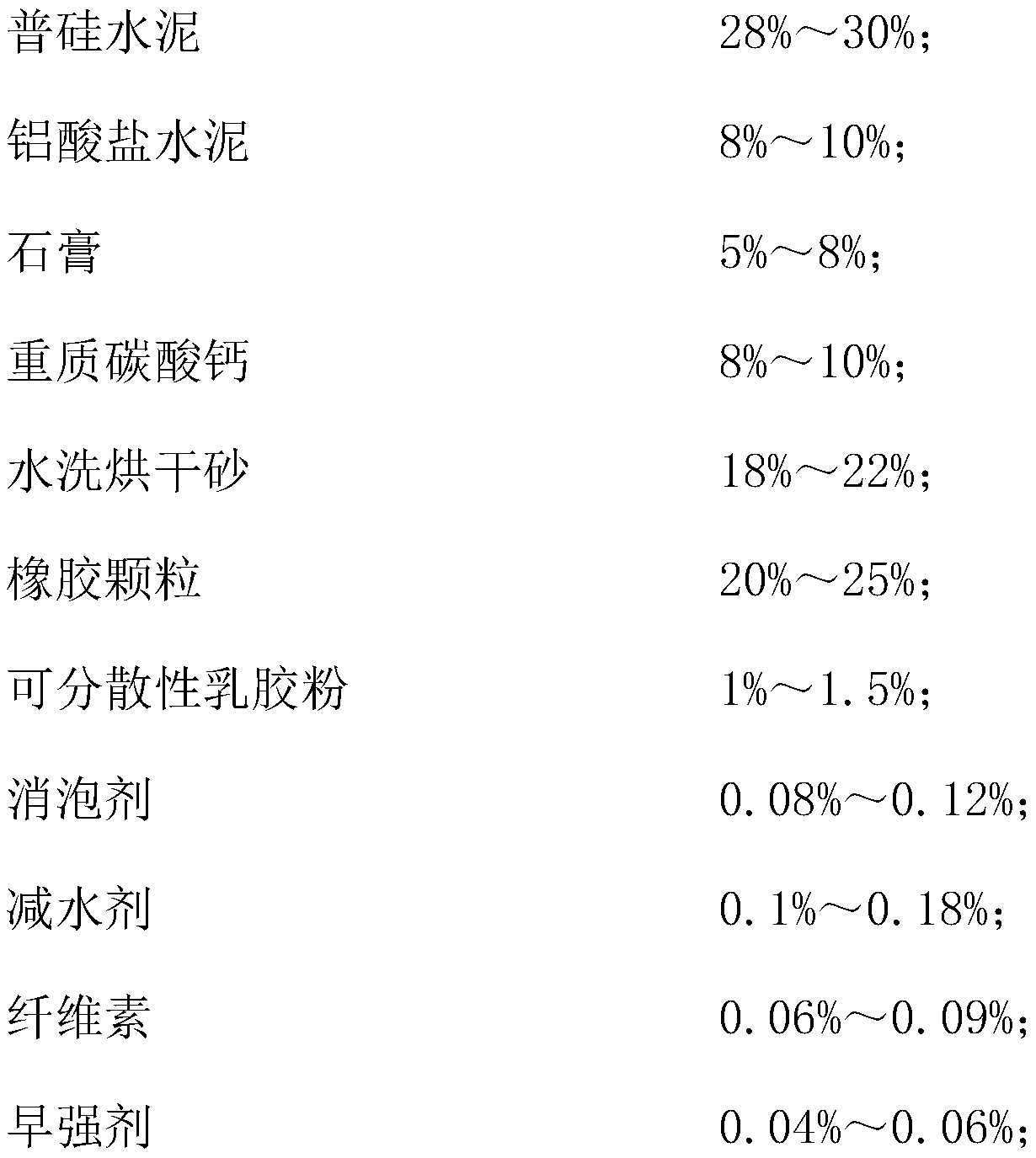

[0016] Two-component cement-based ultra-flexible self-leveling cement, specifically including the following raw materials by weight percentage: ordinary silicon cement 30%; aluminate cement 8.55%; gypsum 8%; heavy calcium carbonate 10%; washed and dried sand 22% %; rubber particles 20%; dispersible latex powder 1%; defoamer 0.08%; water reducer 0.1%; cellulose 0.06%; The washed and dried sand is 70 orders. The rubber particles are 50 mesh. During use, every 25 kilograms of the two-component cement-based super flexible self-leveling cement added 6.5L of acrylic acid emulsion with a solid content of 25% as a stirring liquid.

Embodiment 2

[0018] Two-component cement-based ultra-flexible self-leveling cement, specifically including the following raw materials by weight percentage: ordinary silicon cement 28.43%; aluminate cement 10%; gypsum 7.8%; heavy calcium carbonate 8.74%; washed and dried sand 18% %; rubber particles 25%; dispersible latex powder 1.5%; defoamer 0.12%; water reducer 0.18%; cellulose 0.09%; The washed and dried sand is 110 mesh. The rubber particles are 40 mesh. During use, every 25 kilograms of the two-component cement-based ultra-flexible self-leveling cement added 6.5L of acrylic acid emulsion with a solid content of 25% as a stirring liquid.

Embodiment 3

[0020] Two-component cement-based super flexible self-leveling cement, specifically including the following raw materials by weight percentage: ordinary silicon cement 28%; aluminate cement 9.2%; gypsum 6%; heavy calcium carbonate 10%; washed and dried sand 21% %; rubber particles 24.35%; dispersible latex powder 1%; defoamer 0.08%; water reducer 0.1%; cellulose 0.06%; The washed and dried sand is 70 orders. The rubber particles are 70 mesh. During use, every 25 kilograms of the two-component cement-based super flexible self-leveling cement added 6.5L of acrylic acid emulsion with a solid content of 25% as a stirring liquid.

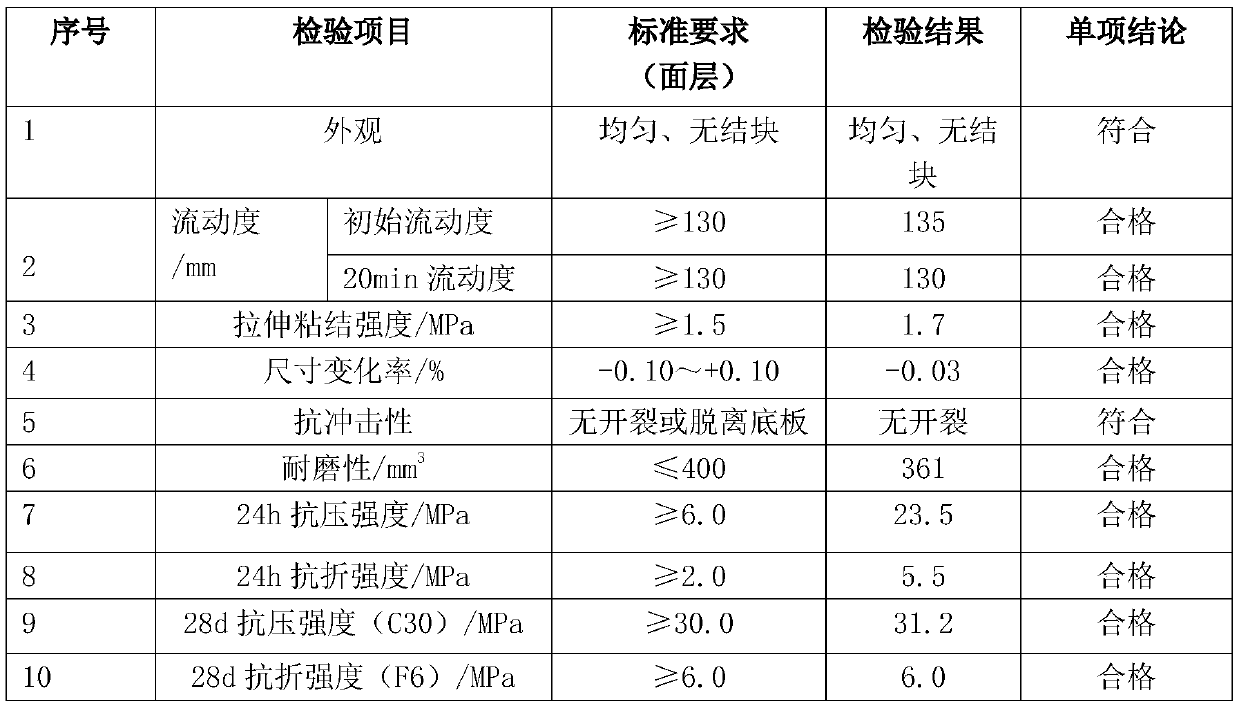

[0021] The cement-based self-leveling mortar prepared in Example 3 was inspected (the inspection basis is JC / T 985-2017 "Cement-based self-leveling mortar for ground"), and the detection data were obtained as follows:

[0022]

[0023] It can be seen that the two-component cement-based ultra-flexible self-leveling cement of the present invention ful...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com