Straw/polymer composite material for public transit facilities, preparation method of composite material and application of composite material

A technology for public transportation and composite materials, applied in the field of straw/polymer composite materials, can solve the problems of poor safety of public transportation facilities, and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

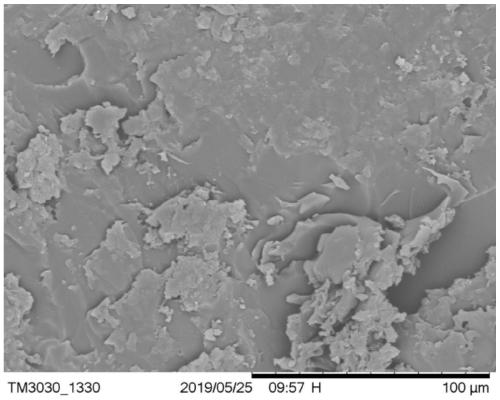

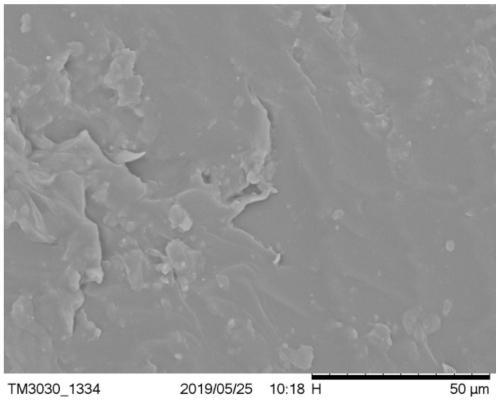

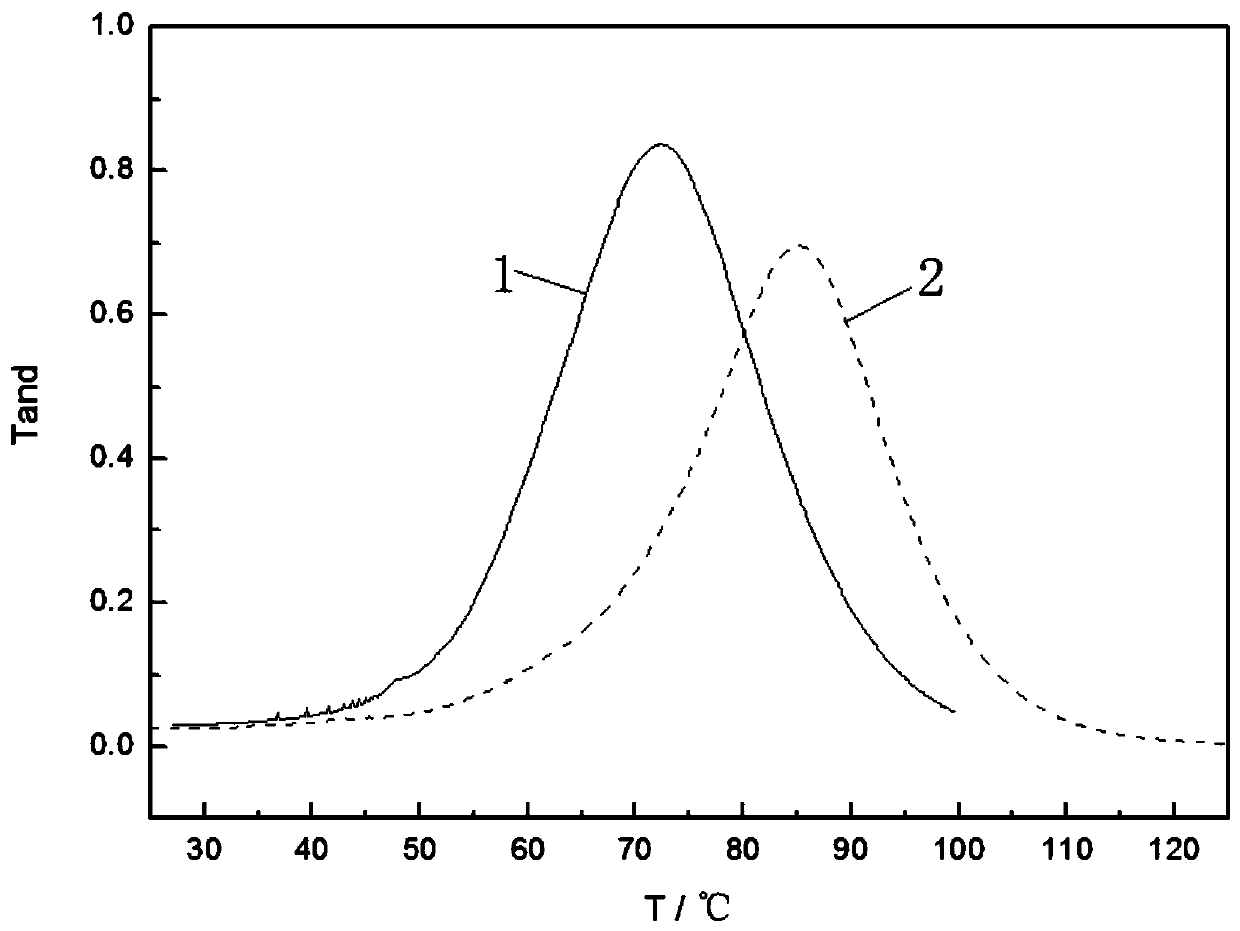

[0024] Embodiment 1: The straw / polymer composite material for public transportation facilities in this embodiment is composed of a thermosetting polymer and straw powder.

[0025] The volume fraction of straw powder in the straw / polymer composite material is 5%.

[0026] The preparation method is as follows: firstly, the straw is made into straw powder, then the straw powder is mixed with a polymer matrix, and finally placed in a molding mold for solidification and molding.

[0027] The straw is corn straw.

[0028] The preparation process of the straw powder is as follows: cut the straw into 2 cm straw sections, then dry them at 110°C for 2 hours, use a pulverizer to crush the dried straw sections, and then dry them at 110°C for 2 hours. hour, and finally pass through a 140 mesh sieve to complete. The drying process is beneficial to the crushing of the straw, and the finer the crushing of the straw, the better the strength of the prepared composite material.

[0029] The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com