A kind of intumescent high-performance fire-proof flame-retardant coating and preparation method thereof

A high-performance technology for fire-resistant and flame-retardant coatings, applied in fire-resistant coatings, coatings, etc., can solve the problems of complex composition, unstable properties of calcium sulfite, land occupation, etc., to improve flame-retardant performance, enhance market competitiveness and The effect of application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

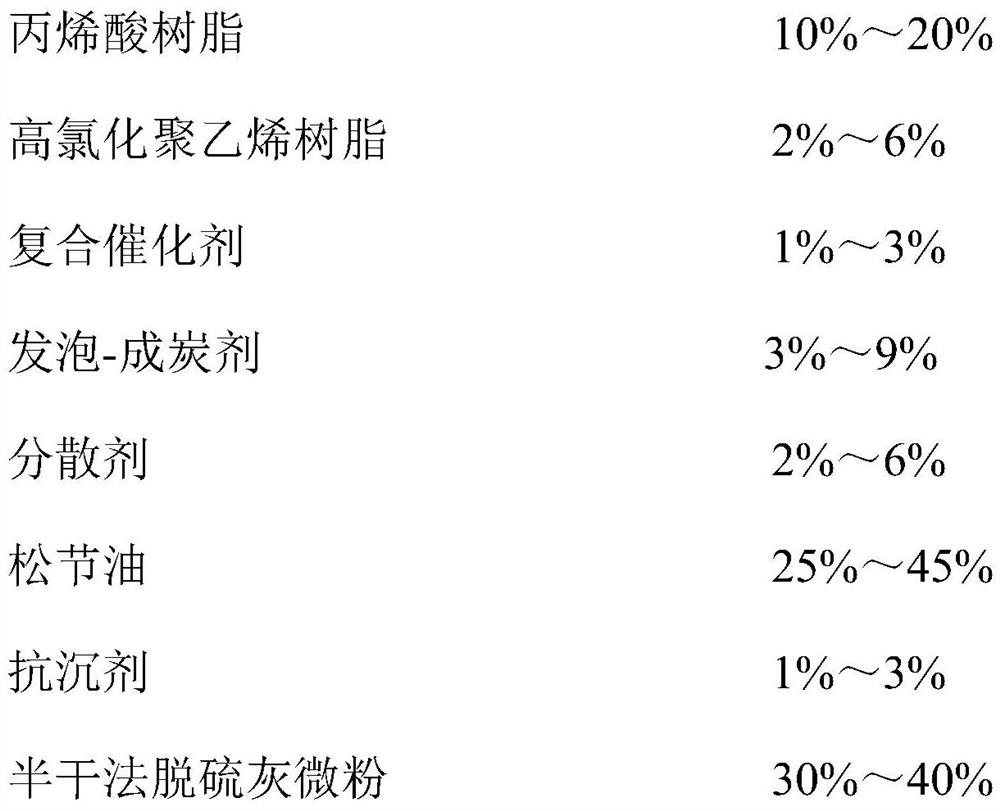

[0024] Taking the preparation of product 100g of the present invention as an example, the components used and their mass proportions are:

[0025]

[0026] The acrylic resin is industrially pure; the highly chlorinated polyethylene resin is industrially pure; the composite catalyst is a mixture of boric acid, amidinourea phosphate and ammonium polyphosphate, and the quality of boric acid, amidinourea phosphate and ammonium polyphosphate is Ratio 1:1:1, boric acid, guanylurea phosphate and ammonium polyphosphate are industrially pure; foaming-char forming agent is a mixture of melamine and pentaerythritol, the mass ratio of melamine to pentaerythritol is 1:3, melamine and pentaerythritol are industrially pure The dispersant is that SRE-4029 is a dispersant, which is industrially pure; the turpentine is industrially pure; the anti-sedimentation agent is F118 anti-settling agent, which is industrially pure; the semi-dry desulfurization ash micropowder The diameter is 15 μm to ...

Embodiment 2

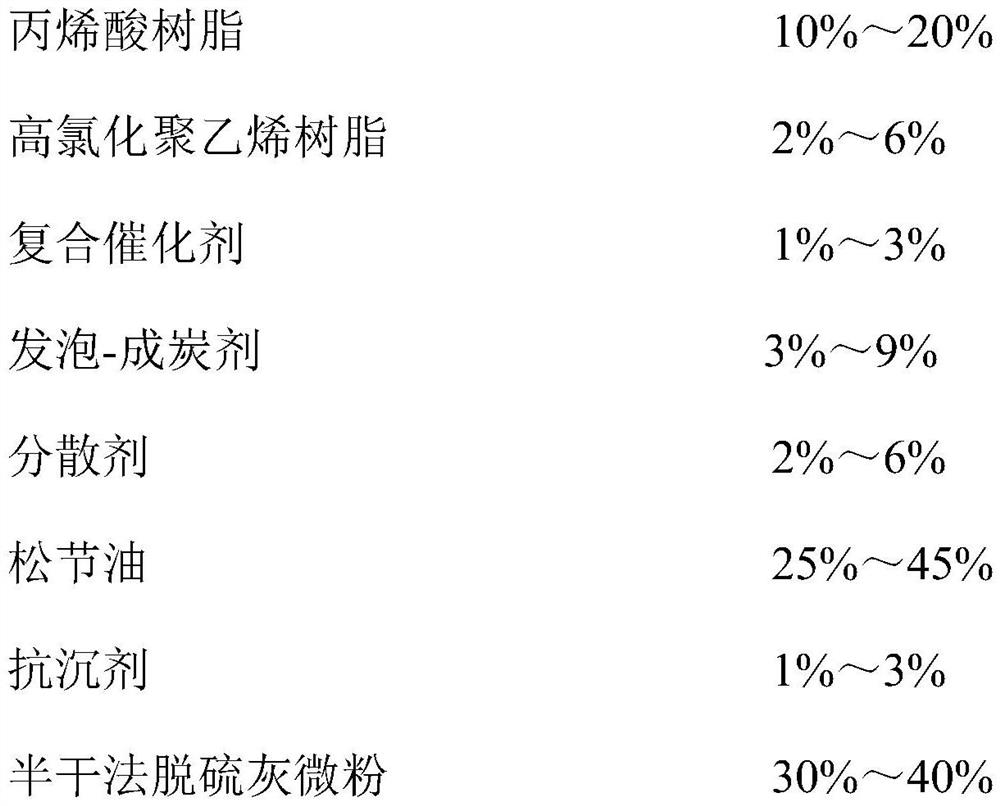

[0031] Taking the preparation of product 100g of the present invention as an example, the components used and their mass proportions are:

[0032]

[0033]The acrylic resin is industrially pure; the highly chlorinated polyethylene resin is industrially pure; the composite catalyst is a mixture of boric acid, amidinourea phosphate and ammonium polyphosphate, and the quality of boric acid, amidinourea phosphate and ammonium polyphosphate is Ratio 1:1:4, boric acid, guanylurea phosphate and ammonium polyphosphate are industrially pure; foaming-char forming agent is a mixture of melamine and pentaerythritol, the mass ratio of melamine to pentaerythritol is 1:2, melamine and pentaerythritol are industrially pure The dispersant is SRE-4029 dispersant, which is industrially pure; the turpentine is industrially pure; the anti-sedimentation agent is F118 anti-settling agent, which is industrially pure; the particle size of the semi-dry desulfurization ash powder 15 μm to 35 μm.

[...

Embodiment 3

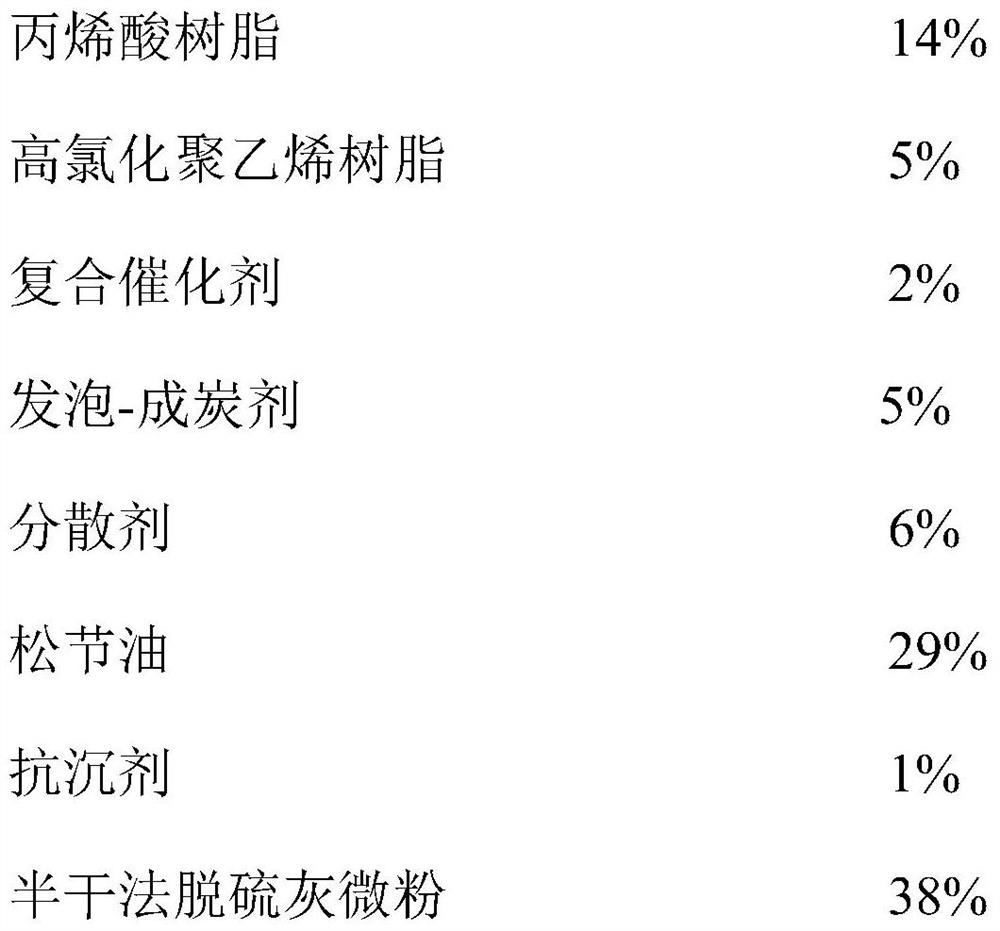

[0038] Taking the preparation of product 100g of the present invention as an example, the components used and their mass proportions are:

[0039]

[0040]

[0041] The acrylic resin is industrially pure; the highly chlorinated polyethylene resin is industrially pure; the composite catalyst is a mixture of boric acid, amidinourea phosphate and ammonium polyphosphate, and the quality of boric acid, amidinourea phosphate and ammonium polyphosphate is Ratio 1:1:3, boric acid, guanylurea phosphate and ammonium polyphosphate are industrially pure; foaming-char forming agent is a mixture of melamine and pentaerythritol, the mass ratio of melamine to pentaerythritol is 1:1, melamine and pentaerythritol are industrially pure The dispersant is SRE-4029 dispersant, which is industrially pure; the turpentine is industrially pure; the anti-sedimentation agent is F118 anti-settling agent, which is industrially pure; the particle size of the semi-dry desulfurization ash powder 15 μm t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com