Method for Improving Purity of Al-zn-mg-cu Alloy Melt

A technology of purity and melt, which is applied in the field of improving the purity of Al-Zn-Mg-Cu alloy melt, and can solve problems such as alloy pollution, smoke pollution, and intense reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

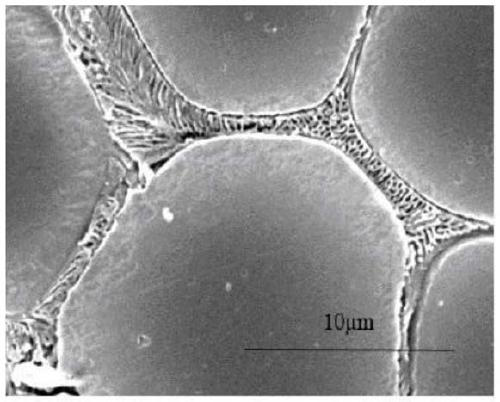

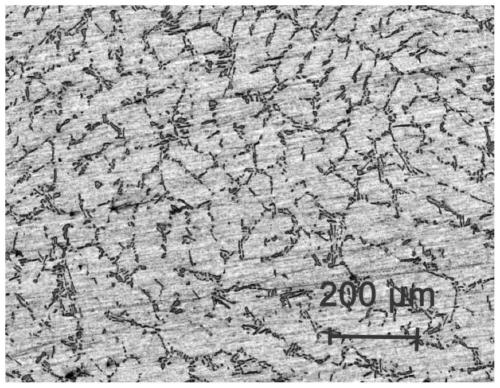

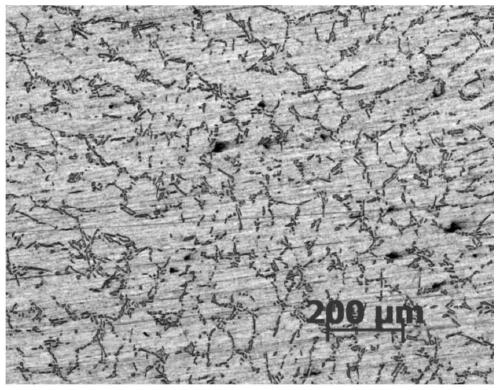

Image

Examples

Embodiment 1

[0026] A method for improving the purity of an Al-Zn-Mg-Cu alloy melt, comprising the following steps:

[0027] S1, use an induction heating furnace to melt the raw material of aluminum alloy to obtain a melt, adjust the temperature of the melt to 700°C, wherein, in terms of mass percentage, the aluminum alloy is composed of 9% Zn, 2.3% Mg, 2.5% Cu, 0.15% % Zr and the remainder Al composition.

[0028] Prepare the refining agent, the refining agent is made by uniformly mixing hexachloroethane and MgO powder, hexachloroethane is 0.2wt% of the melt, and the MgO powder is 0.2wt% of the melt; the refining agent is divided into N parts and each part Wrap it with aluminum foil to obtain N refining bags, N>1, and the mass of refining agent in each refining bag is 200g. When adding, add in batches according to the bag, put N refining bags into the melt successively at intervals, among them, use a bell jar to press the refining bag to a position where the distance from the melt surfac...

Embodiment 2

[0035] A method for improving the purity of an Al-Zn-Mg-Cu alloy melt, comprising the following steps:

[0036] S1, use an induction heating furnace to melt the raw material of aluminum alloy to obtain a melt, adjust the temperature of the melt to 710°C, wherein, in terms of mass percentage, the aluminum alloy is composed of 9.1% Zn, 2.6% Mg, 2.6% Cu, 0.2% % Zr, 0.1% Yb and the remainder Al composition.

[0037]Prepare the refining agent, the refining agent is made by uniformly mixing hexachloroethane and MgO powder, hexachloroethane is 0.3wt% of the melt, and the MgO powder is 0.5wt% of the melt; the refining agent is divided into N parts and each part Wrap it with aluminum foil to obtain N refining bags, N>1, and the mass of refining agent in each refining bag is 200g. Add in batches according to the bag, put N refining bags into the melt successively at intervals, wherein, use a bell jar to press the refining bag to a position where the distance from the melt surface is 2 / ...

Embodiment 3

[0043] A method for improving the purity of an Al-Zn-Mg-Cu alloy melt, comprising the following steps:

[0044] S1, use an induction heating furnace to melt the raw materials of aluminum alloy to obtain a melt, and adjust the temperature of the melt to 710°C, wherein, in terms of mass percentage, the aluminum alloy consists of 9.3% Zn, 2.8% Mg, 2.7% Cu, 0.25% % Zr, 0.2% Yb and the remainder Al composition.

[0045] Prepare the refining agent, the refining agent is made by uniformly mixing hexachloroethane and MgO powder, hexachloroethane is 0.4wt% of the melt, and the MgO powder is 1wt% of the melt; the refining agent is divided into N parts and each part is used Wrap with aluminum foil to obtain N refining bags, N>1, and the mass of refining agent in each refining bag is 200g. Put N refining bags successively into the melt at intervals, among them, use a bell jar to press the refining bag to a position where the distance from the liquid surface of the melt is 2 / 3 of the melt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com