Variable stiffness and energy dissipation type fabricated transverse connection structure

A horizontal connection and assembly technology, applied in the seismic field of building structures, can solve the problems of long time consumption, environmental pollution, and many materials for cast-in-place connection, and achieve the effect of convenient overall replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing.

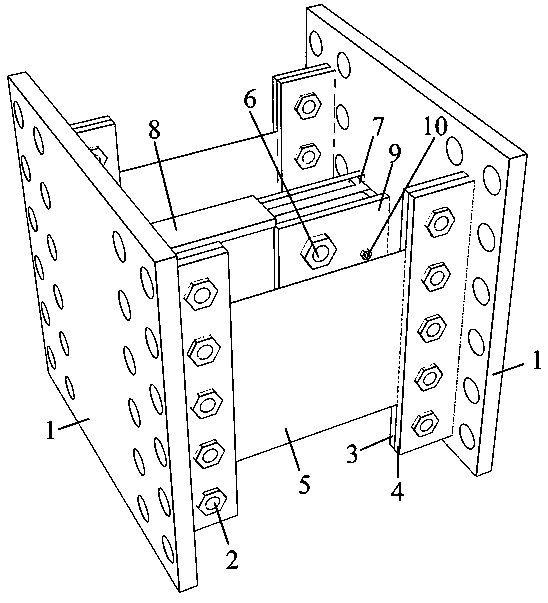

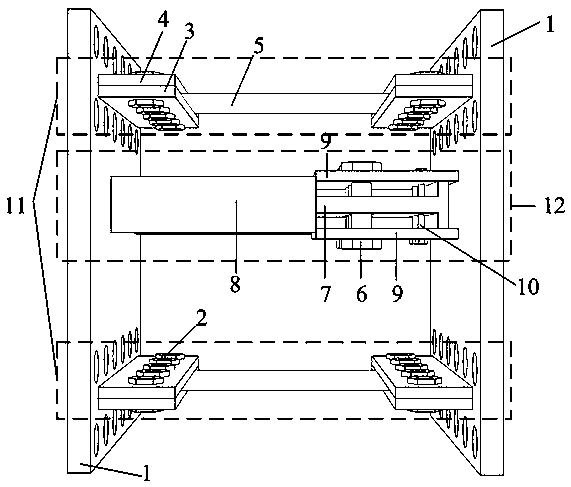

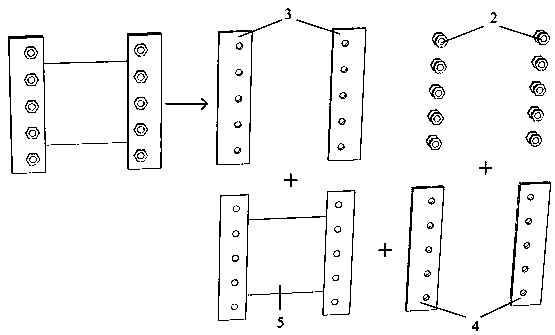

[0034] Such as figure 1 As shown, it is a schematic diagram of the top view structure of the present invention. An assembled transverse connection damper according to the present invention includes an energy dissipation area 11 , a lifting area 12 and left and right connecting end plates 1 . The energy-dissipating area 11 includes energy-dissipating steel plates 5 , bolted plates 3 and 4 on the inner and outer sides, and high-strength bolts 2 . The lifting area 12 includes variable-section steel plates 7 and stiffeners 8 , buckling restraint plates 9 on both sides, ordinary bolts 6 and positioning bolts 10 .

[0035] Such as figure 2 As shown, it is a schematic diagram of the front view structure of the present invention. The energy dissipation area 11 is distributed on both sides of the lifting area 12. The inner bolt connection plate 3 of the energy dissipation area 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com