Thin-walled frame-type horizontal warehouse and construction method thereof and special equipment

A construction method and technology of special equipment, which are applied in building structures, buildings, building components, etc., can solve the problems of large labor-consuming workload, increased food storage costs, and non-compliance with environmental protection requirements, so as to achieve difficult construction and reduce pressure. , the effect of saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

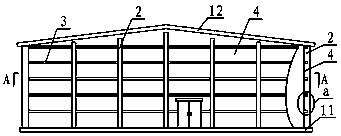

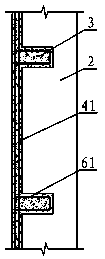

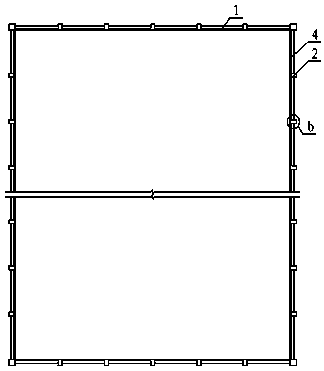

[0053] A thin-walled frame-type bungalow warehouse and its construction method and special equipment, its composition includes: a frame-type warehouse body 1, the frame-type warehouse body is connected to a base 11 and a warehouse roof 12, and the frame-type warehouse body 1 includes A group of reinforced concrete columns 2 positioned on the four walls of the wall, with reinforced concrete connecting beams 3 between the reinforced concrete columns, forming the support system of the warehouse roof 12, the reinforced concrete columns 2 and the

[0054] The reinforced concrete connecting beam 3 is connected to the reinforced concrete wall 4.

Embodiment 2

[0056] The thin-walled frame-type bungalow warehouse and its construction method and special equipment described in Embodiment 1, the surface of the reinforced concrete wall has a corrugated surface 51 formed by solidification of the corrugated formwork 5, and the reinforced concrete wall has steel bars Net 41, one side of the reinforced concrete wall has an insulation layer 42.

Embodiment 3

[0058] The thin-walled frame-type one-storey warehouse described in Embodiment 1 or 2 and its construction method and special equipment, the reinforced concrete column is a semi-trapezoidal structure 21, and the reinforced concrete connecting beam is 3-8 floors from bottom to top , The spacing gradually increases from bottom to top, and the surface of the reinforced concrete column has corrugations 52 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com