A strip-fill mining method for extra-thick coal seams relying on steel formwork trolleys

A technology of steel mold trolley and extra-thick coal seam, which is applied in the direction of filling, special mining, ground mining, etc., can solve the problems of low efficiency, low degree of modernization, high cost, etc., and achieve the effect of saving manpower and simplifying the construction method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

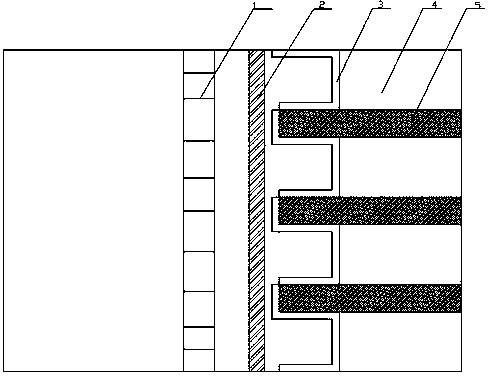

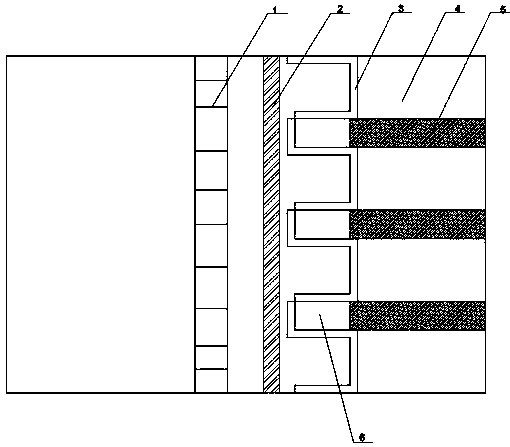

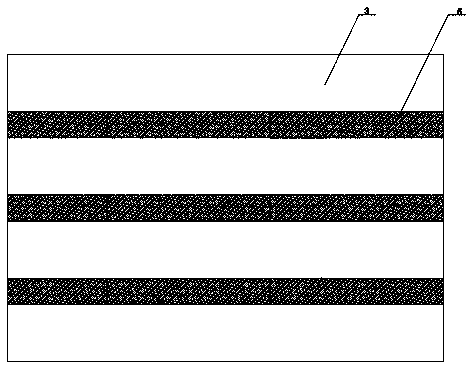

[0042] Such as Figure 4 As shown, the steel mold trolley used in the present invention has a structure comprising: a traveling mechanism located at the bottom end of the trolley, and track stoppers and trolley belt clamps at the bottom ends of the front and rear sides, the upper end of the traveling mechanism and the trolley The gantry system is connected, and the gantry system includes a column directly connected to the upper end of the traveling mechanism and a platform beam on the upper side of the column. The side of the column is supported by the main cylinder 14 of the trolley, the additional disturbance jack 20 on the left, and the additional disturbance jack on the right. 16 is respectively connected with the left and right side formworks, and the top of the platform beam is connected with the top formwork 13 by the oil cylinder, and for the formwork of trolley, thickened high-strength steel plate is selected for use. The top formwork 13 adopts a plane type, and the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com