Hydrogen energy power generation system utilizing metal hydrogen storage material

A hydrogen storage material and power generation system technology, applied in the direction of machines/engines, steam engine devices, mechanical equipment, etc., can solve the problems of small generator power generation, low system energy conversion rate, limited promotion value, etc., to achieve energy saving and emission reduction Economic benefits, the effect of creating economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

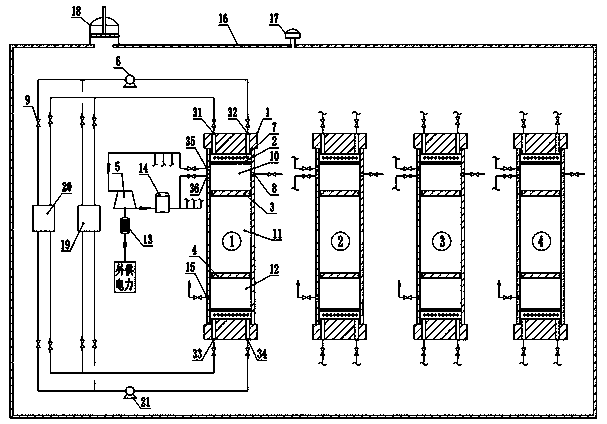

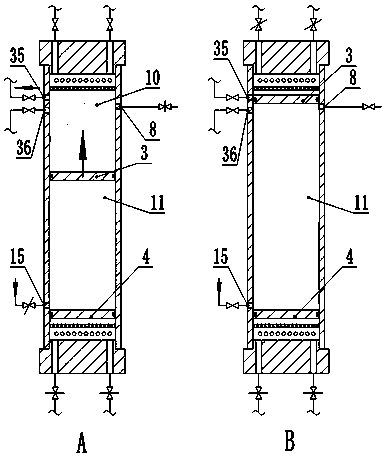

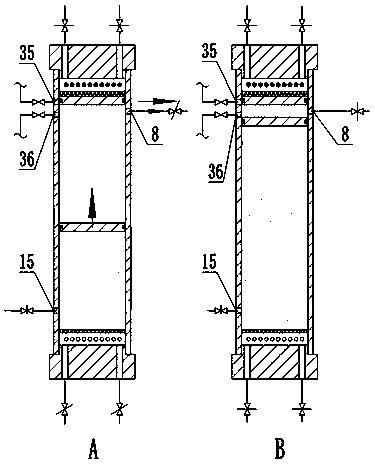

[0020] The present invention utilizes the metal hydrogen storage material hydrogen energy generation system such as figure 1 As shown, it includes four cylinders 1 , an expander 5 , a generator 13 , a hydrogen buffer tank 14 , a heat accumulator 19 and a cold accumulator 20 . The generator is connected to the shaft of the expander, and the generator is connected to an external power grid. The expander 5 drives the generator 13 to run to generate electricity for external supply. Cylinder 1 includes an upper end cover, a lower end cover and a cylinder body. The cylinder body is provided with a hydrogen gas inlet 36, a hydrogen gas outlet 35, a nitrogen gas inlet 15 and a nitrogen gas outlet 8, and a hydrogen gas inlet 36 and a hydrogen gas outlet 35 with a valve 9. 3 sets The working hydrogen outlet 35 of the cylinder 1 is connected to the hydrogen inlet of the expander 5, and the hydrogen outlet of the expander is connected to the hydrogen inlet 36 of the four cylinders 1 throu...

Embodiment 2

[0033] Another embodiment of the hydrogen power generation system using metal hydrogen storage materials in the present invention is as follows Figure 5As shown, four cylinders 1, an expander 5, a generator 13, a hydrogen buffer tank 14, and a turbocharger 37 are included. The upper end cover of each cylinder 1 cylinder is provided with an upper hydrogen outlet 31 and an upper hydrogen inlet 32, and the lower end cover is provided with a lower hydrogen outlet 33 and a lower hydrogen inlet 34. The upper hydrogen outlet 31 of No. 1 cylinder passes through a turbocharger 37 and hydrogen Circulation pump 38 is connected to No. 2, No. 3, the lower hydrogen inlet 34 of No. 4 cylinder, and the lower hydrogen outlet 33 of No. 1 cylinder is connected to No. 2, No. 3, No. 4 cylinder by turbocharger 37 and hydrogen circulation pump 38 On the hydrogen inlet 32, the connecting pipeline is provided with a valve 9. The lower hydrogen outlet 33 of the same number cylinder is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com