Vehicle pull line type displacement measuring device

A displacement measurement and pull-wire technology, which is applied in the automotive field, can solve the problems of vehicle local stress concentration, relative displacement in the longitudinal and lateral directions, and low accuracy of measurement data, so as to reduce local stress concentration, improve displacement test accuracy, and test accuracy high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The embodiments of the present invention are described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

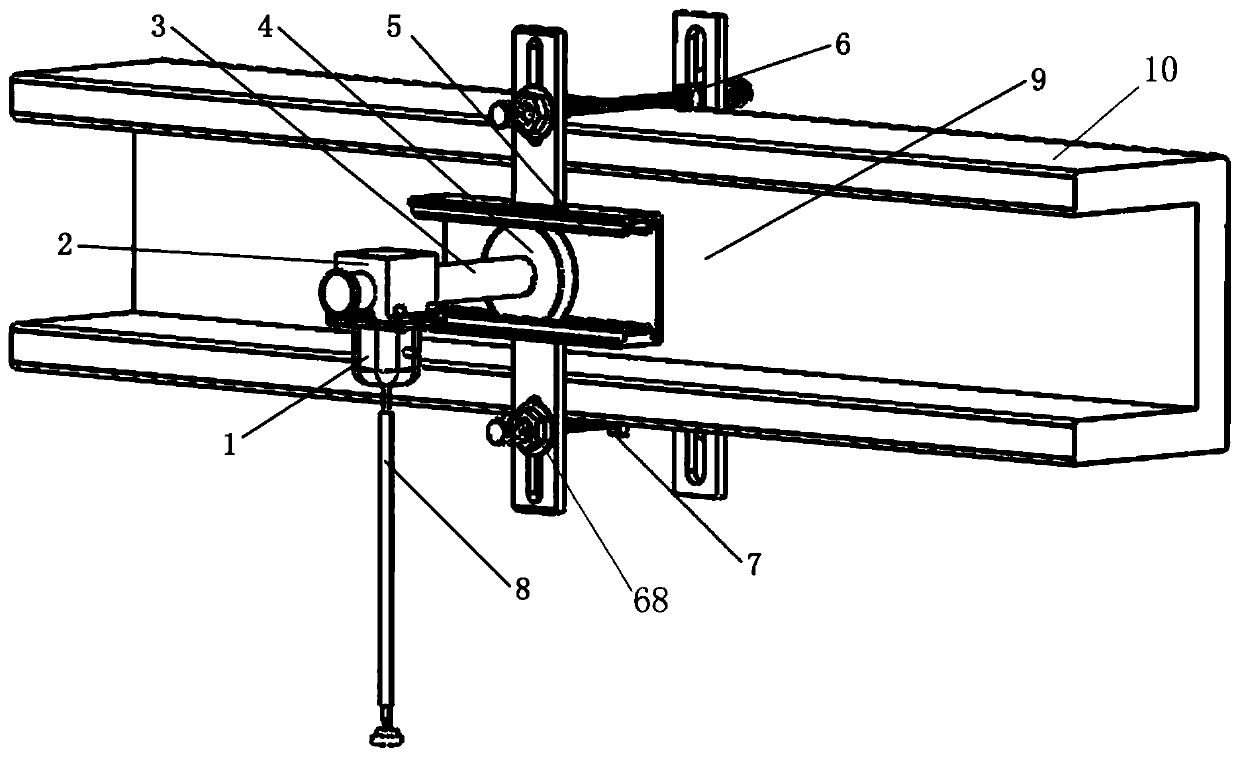

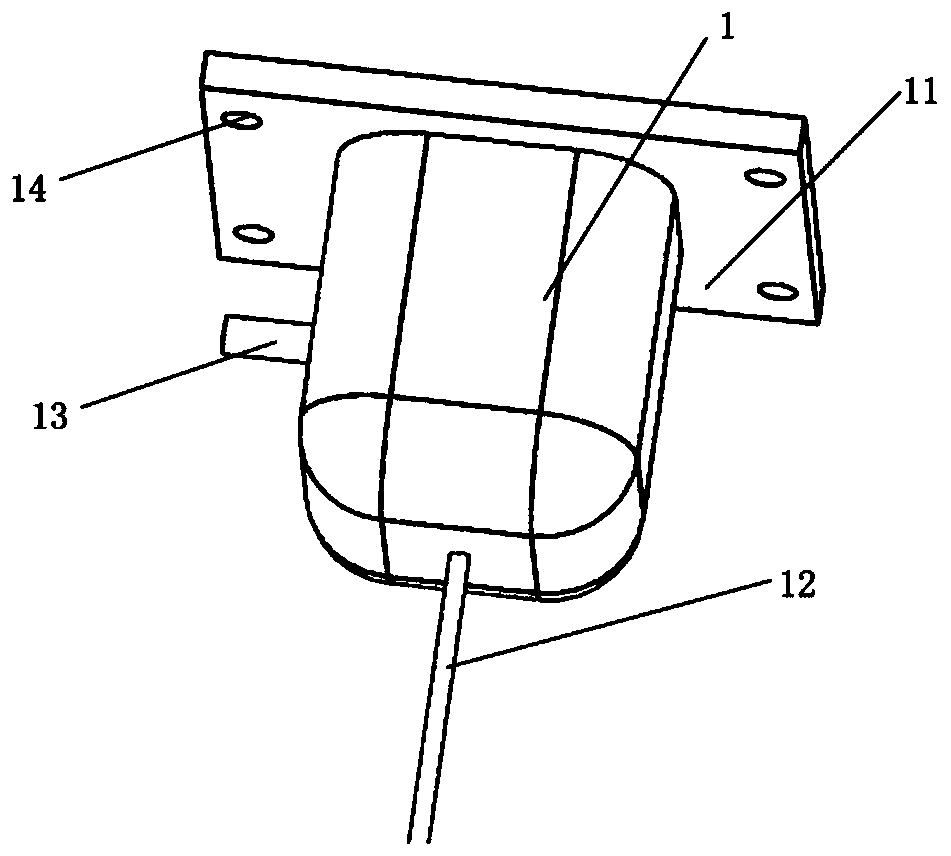

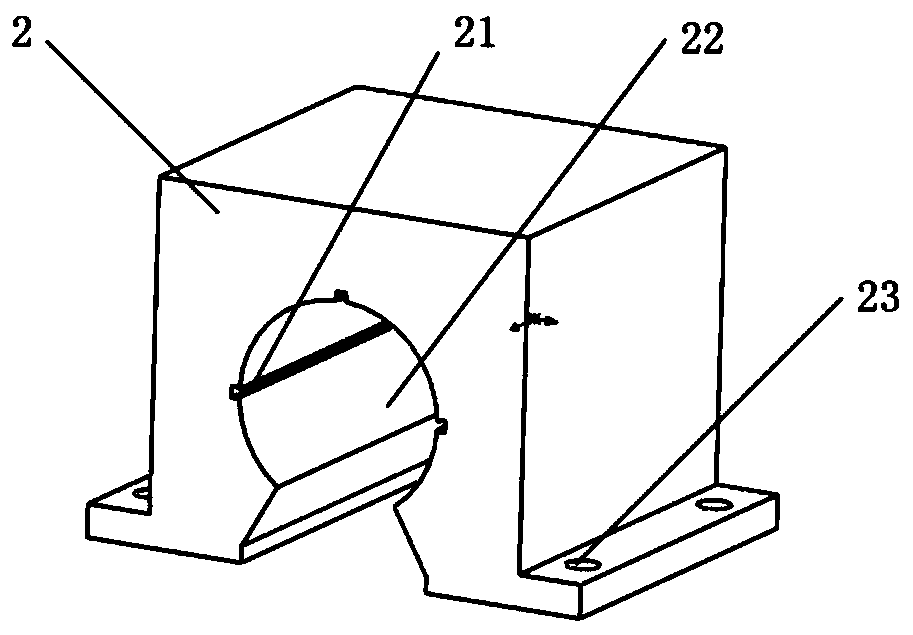

[0038] like Figure 1-Figure 12 As shown, the present invention discloses a vehicle pull-wire displacement measuring device, which includes a pull-wire displacement sensor 1, a first moving component, a second moving component and a locking mechanism 6. The first moving component includes a first guide member and a The first moving piece moves along the first guide piece, the second moving assembly includes a second guide piece and a second moving piece that can move along the second guide piece, the pull-wire displacement sensor 1 is mounted on the second moving piece, the first moving piece Two guide members are installed on the first moving member, the moving directions of the first moving member and the second moving member are perpendicular, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com