Fine crack making device and method of real rock sample

A technology for rock samples and manufacturing devices, which is applied in the preparation of test samples, measuring devices, sampling, etc., and can solve the problems of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

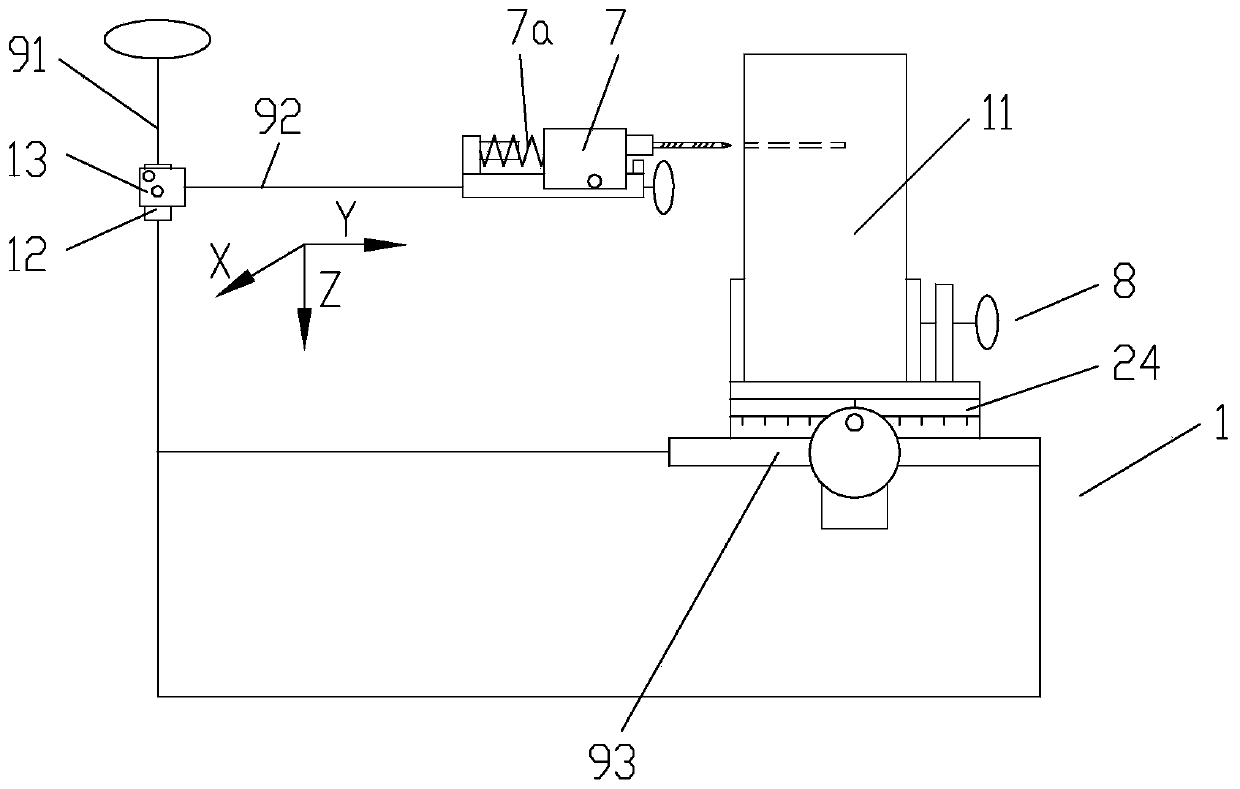

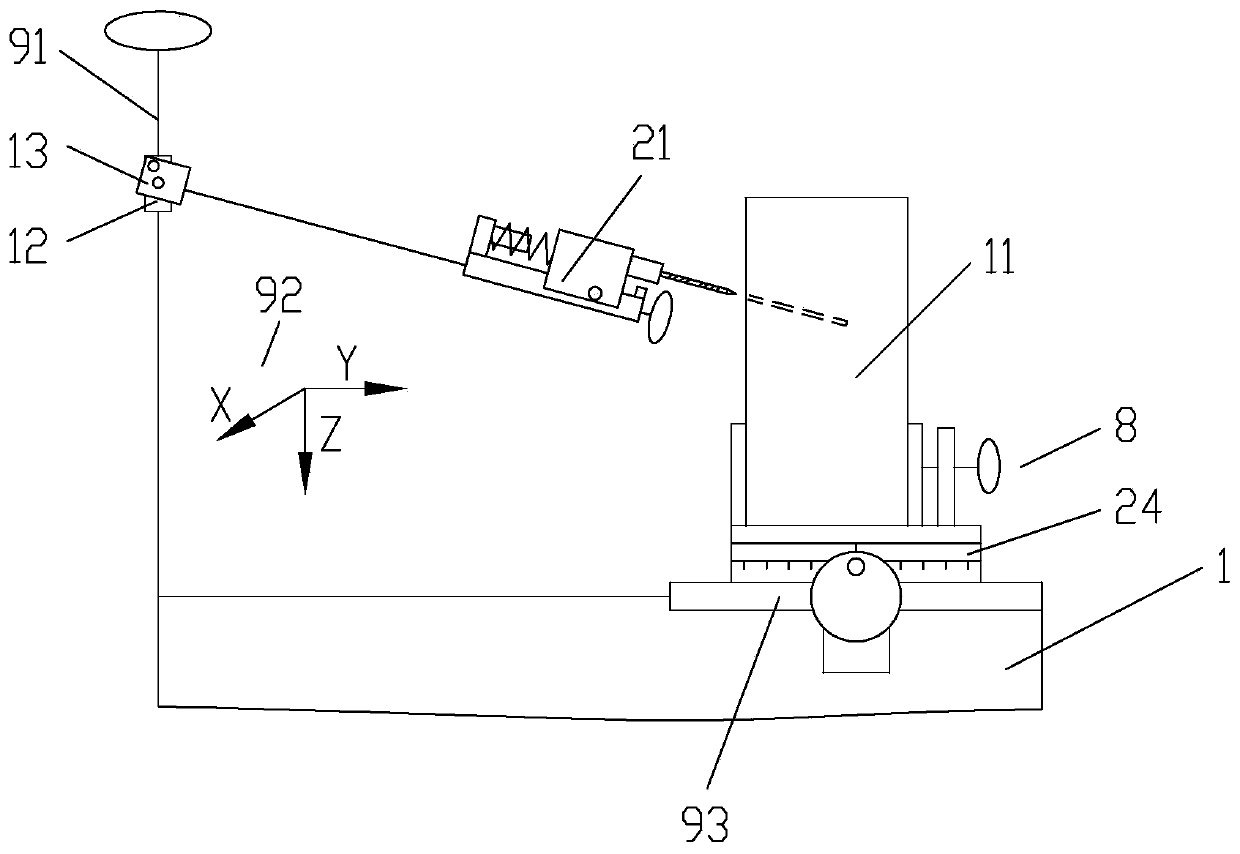

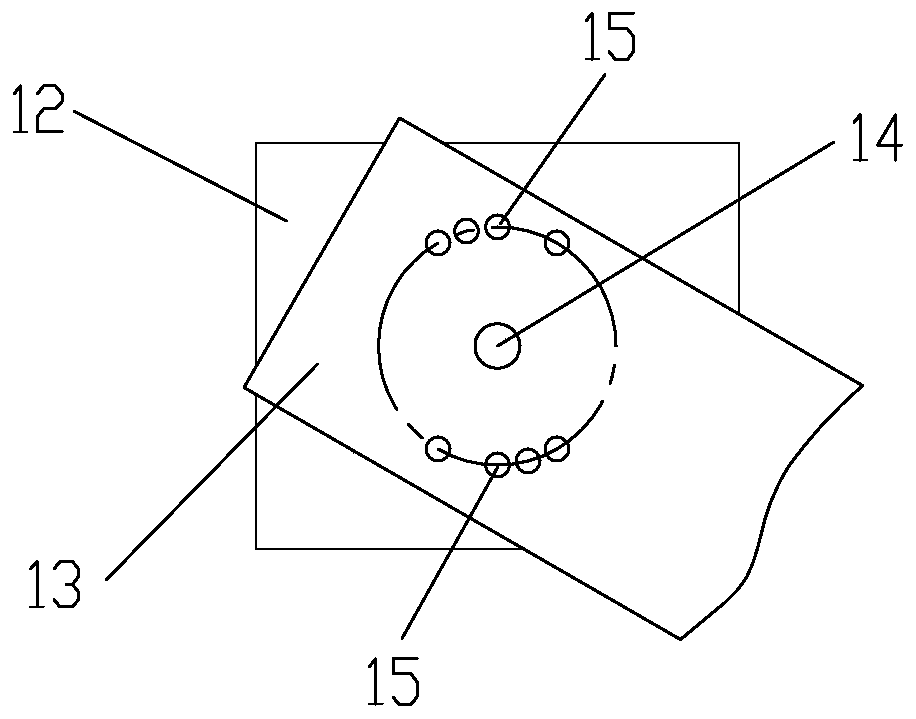

[0043] Example 1, see figure 1 , figure 2 , image 3 , a fine crack making device for a six-sided cube real rock sample, comprising a base platform 1, a high-speed electric drill 7, a sample holder 8, and a position adjustment device; the high-speed electric drill 7 and the sample holder 8 pass through The position adjustment device is connected to the base platform 1; the position adjustment device is composed of a lifting device 91, a longitudinal displacement device 92 and a sample displacement device 93: the longitudinal displacement device 92 is arranged on the lifting device 91 through an angle adjuster , and be connected with the lifting device 91 in a liftable structure; the angle adjuster has a structure with an adjustable pitch angle; the sample holder 8 is arranged on the sample shifting device 93 through the turntable 24, wherein the turntable 24 The rotating member is fixedly connected with the sample holder 8, and the fixed part of the turntable 24 is fixedly ...

Embodiment 2

[0048] Example 2, such as Figure 5 , Figure 6 , a device for making fine fractures of a disc real rock sample, wherein the sample holder 8 is used for making cracks in the disc sample, and the two ends of the sample are set horizontally to form a horizontal or inclined surface on the cylinder crack. The sample holder 8 includes a bottom plate 81, and one end of the bottom plate 81 is vertically provided with a column 101, and the column 101 is screwed with a horizontally arranged jacking rod 102 through a threaded hole. The arc-shaped positioning block 103 on the surface of the disk sample cylinder, the end of the clamping rod 102 is provided with a clamping handle; one side wall of the column 101 is equipped with an upper clamping block 104 and a lower clamping block through a dovetail guide rail pair structure 105, the upper clamping block 104 and the lower clamping block 105 are used to clamp the sample through the two ends of the disc sample; the upper clamping block 1...

Embodiment 3

[0050] Example 3, see Figure 7 , Figure 8 , a device for making fine fractures of disc real rock samples, wherein the sample holder 8 is used for making disc sample cracks, and the two ends of the sample are vertically arranged to form a horizontal or inclined surface on the end faces crack. The main difference between the structure of the sample holder 8 and that of Embodiment 2 is that the front end of the clamping rod 102 is provided with a flat clamping plate 108, and the clamping parts of the upper clamping block 104 and the lower clamping block 105 are provided with There are arc clamping blocks 109. The rest are with Figure 5 , Figure 6 The structures shown are the same.

[0051] The rest of the structure of this embodiment is the same as that of Embodiment 2, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com