TEC temperature control driving circuit and control strategy thereof

A driving circuit and circuit technology, applied in the direction of temperature control, non-electric variable control, control/regulation system, etc., can solve the problems of output accuracy limitation, large output voltage ripple, occupying large circuit area, etc., and achieve high-precision temperature control , smooth transition, good linearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with embodiment, but protection scope of the present invention is not limited to this:

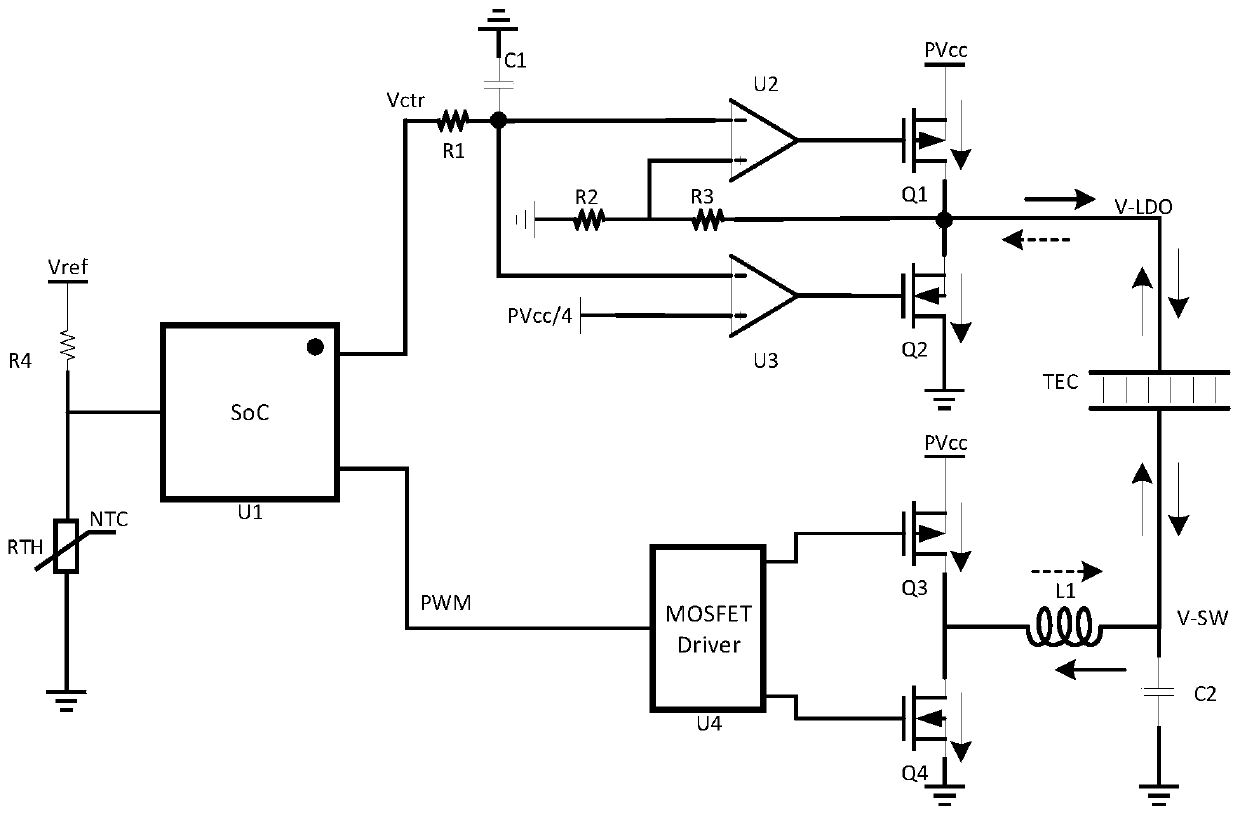

[0046] combine image 3 , a TEC temperature control drive circuit, which includes a main control chip SoC, a linear voltage regulator LDO, a current sink circuit and a switching power supply SW circuit:

[0047]-The main control chip SoC generates the control voltage Vctr of the input terminal of the linear voltage regulator LDO and the current sink circuit, the PWM signal of the input terminal of the switching power supply SW circuit, and detects the voltage feedback value of the thermistor.

[0048] -The output end of the linear voltage regulator LDO is connected to the LDO end of the TEC to provide the input voltage V-LDO, the linear voltage regulator LDO includes the first operational amplifier U2 and the first PMOS transistor Q1 (the adjusting tube in the linear voltage regulator LDO can also be is like Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com