Windmill-shaped thin-walled tube structure energy absorption system capable of achieving multi-dimensional self-locking and easy to assemble

A windmill-shaped, thin-walled tube technology is applied in the field of energy absorption systems, which can solve the problems of increasing installation time and labor costs, and achieve the effects of good flexibility and adjustability, less time-consuming, and easy disassembly and installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Analysis of the side load of a multi-dimensional self-locking windmill-shaped thin-walled tube structure that is easy to assemble and an energy-absorbing system

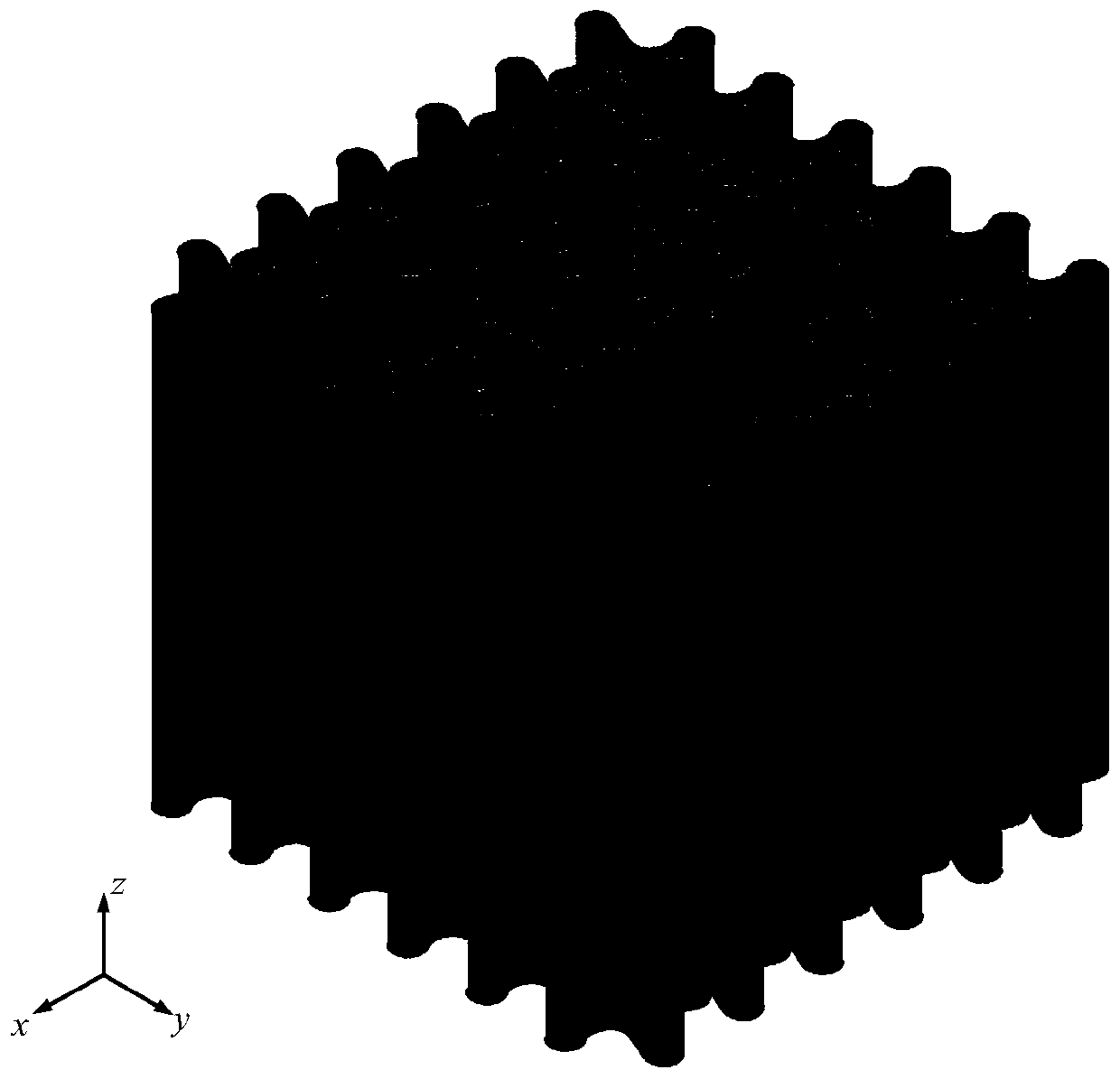

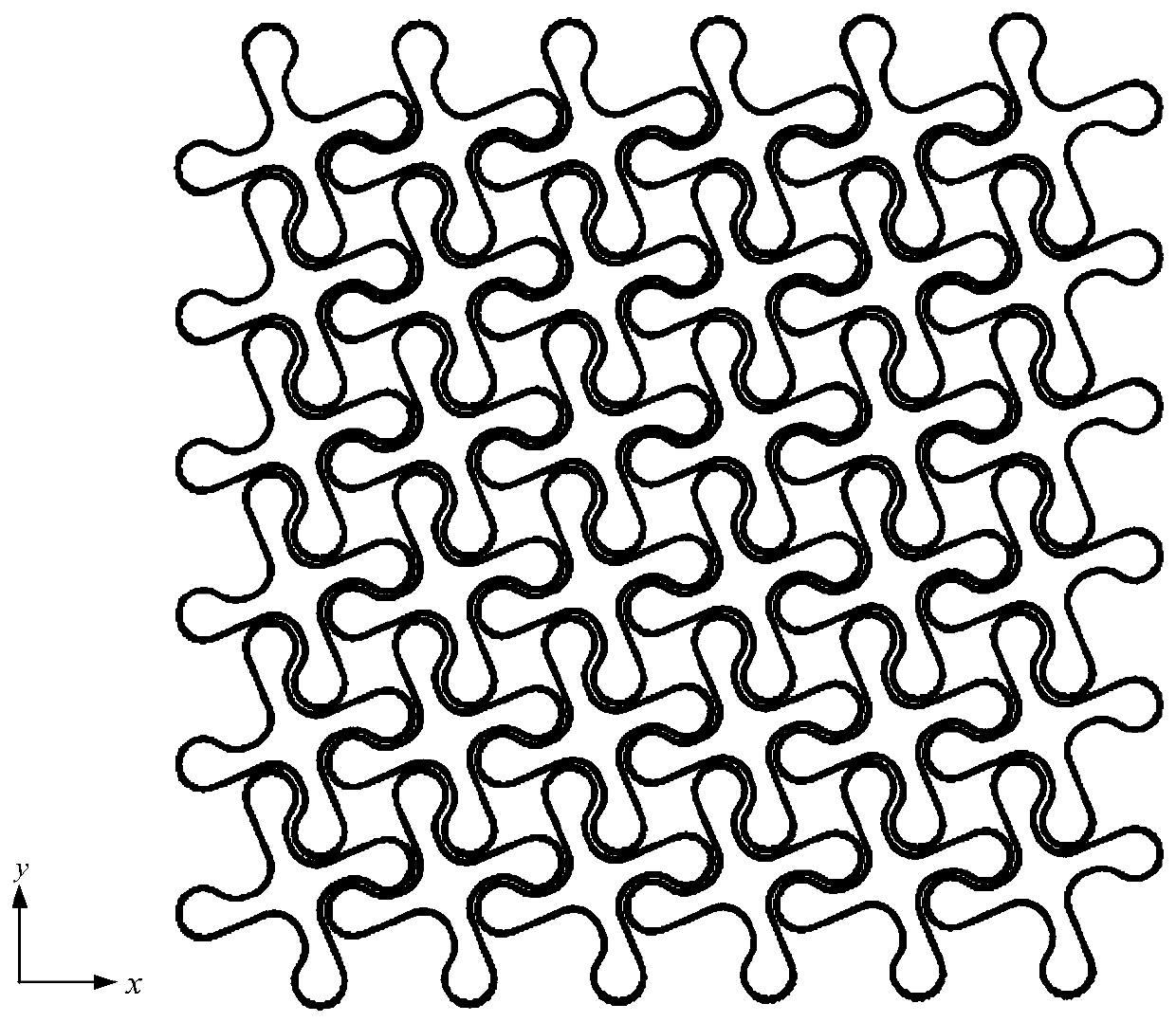

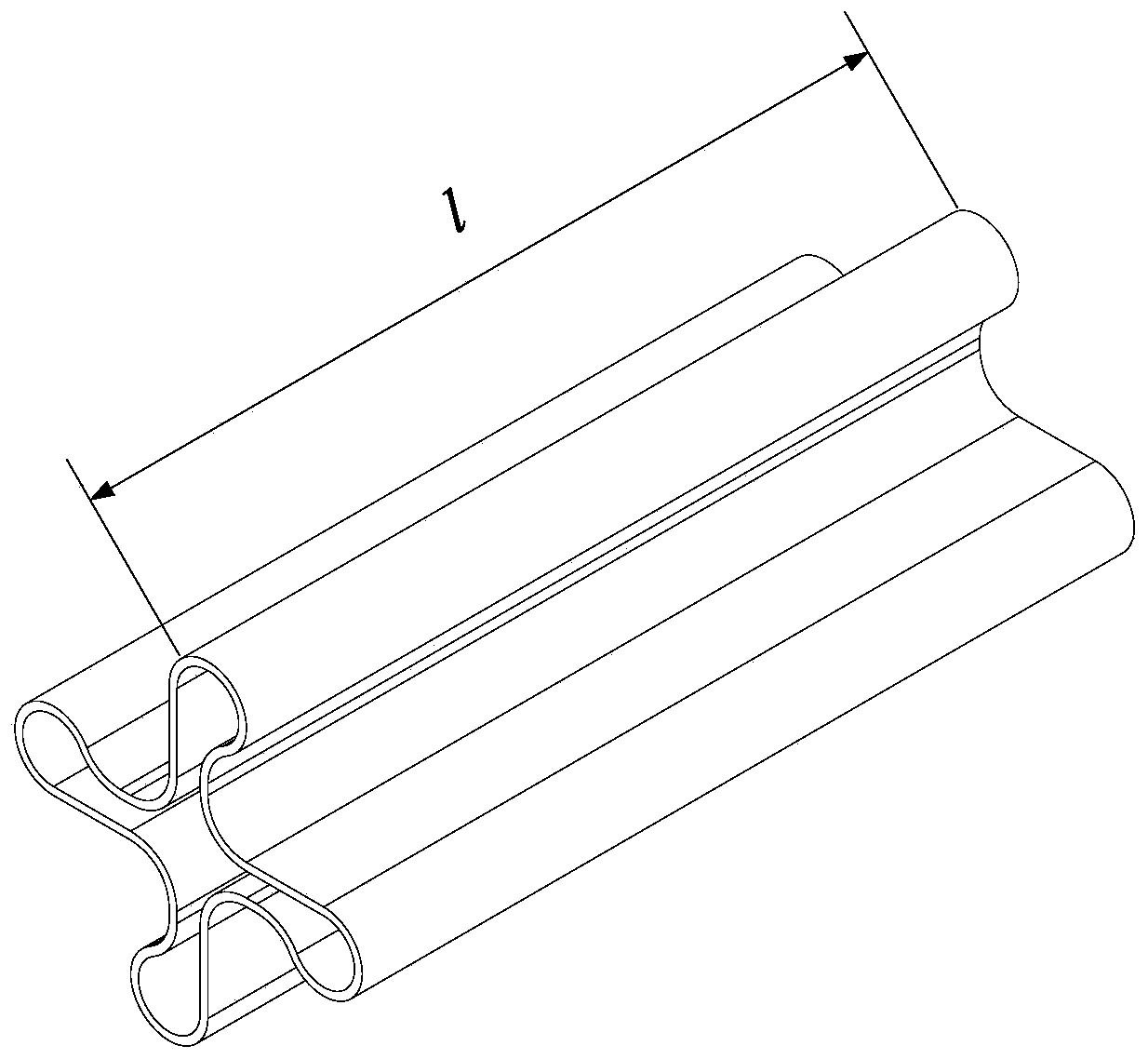

[0035] The energy-absorbing effect of the installed corresponding multi-dimensional self-locking energy-absorbing system under lateral load is calculated by simulation. By staggering 36 windmill-shaped thin-walled tube sub-structures to form a combined structure of 6 rows and 6 columns. The parameters of a single substructure are as follows: the radius of the thin-walled circular tube r=10mm, the width of the narrow thin plate w=20mm, the chamfering radius p=10mm, the thickness t=0.5mm, and the axial length l=367mm. ABAQUS / Explicit is used for dynamic simulation.

[0036] Set the speed of the impacting object as v=72km / h=20m / s, the mass of the impacting object m=133kg, and calculate the impact energy E=1 / 2mv 2 =1 / 2×133×20 2 J=2.66×10 4 J. According to the numerical simulation, the force-displac...

Embodiment 2

[0037] Example 2: Analysis of the longitudinal load of a multi-dimensional self-locking windmill-shaped thin-walled tube structure that is easy to assemble and absorb energy

[0038] The energy-absorbing effect of the installed corresponding multi-dimensional self-locking energy-absorbing system under longitudinal load is calculated by simulation. By staggering 36 windmill-shaped thin-walled tube sub-structures to form a combined structure of 6 rows and 6 columns. The parameters of a single substructure are as follows: the radius of the thin-walled circular tube r=10mm, the width of the narrow thin plate w=20mm, the chamfering radius p=10mm, the thickness t=0.5mm, and the axial length l=367mm. ABAQUS / Explicit is used for dynamic simulation.

[0039] Set the speed of the impacting object as v=144km / h=40m / s, and the mass of the impacting object as m=266kg. Calculated total impact energy E=1 / 2mv 2 =1 / 2×266×40 2 J=2.128×10 5 J. According to the numerical simulation, the forc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com