Method for adjusting ore slurry liquid level and foam thickness of coal flotation machine

An adjustment method and flotation machine technology, applied in the field of separation, can solve the problems of observing the slurry level, adjustment, and dependence, and achieve the effects of eliminating the influence of human factors, ensuring the flotation effect, and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

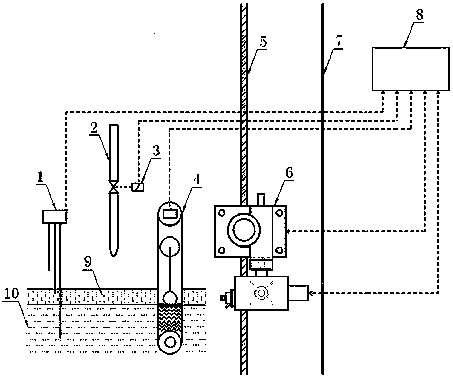

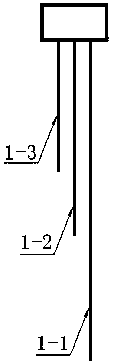

[0021] At present, there are not only a wide variety of liquid level sensors, but also greatly improved detection accuracy, which provides great convenience for the detection of slurry liquid level. The thickness of the foam can be detected according to the conductivity of the foam layer. The detection equipment has a wide range of options, and the actuator technology has also been developed rapidly. The present invention combines the controller 8, the actuator (the dosing volume regulating valve 3 and the gate height regulating device 6), the liquid level sensor 4, and the electrode foam thickness sensor 1 together to intelligently detect the pulp liquid level and foam thickness And adjustments have achieved satisfactory results.

[0022] The liquid level sensor 4 is a pressure liquid level gauge, a floating ball liquid level gauge, an electronic ruler liquid level gauge, an ultrasonic liquid level gauge, a laser ranging liquid level gauge, a radar liquid level gauge or a mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com