Deep sea submersible vehicle pressure-proof body limiting and shrinkage deformation compensating device and mounting method thereof

A compensating device and shrinkage deformation technology, which is applied in transportation and packaging, ship parts, ships, etc., can solve the problems of strength and stability, unfavorable ultimate bearing capacity of pressure-resistant bodies, etc., and achieve compact structure, ensure strength and rigidity, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

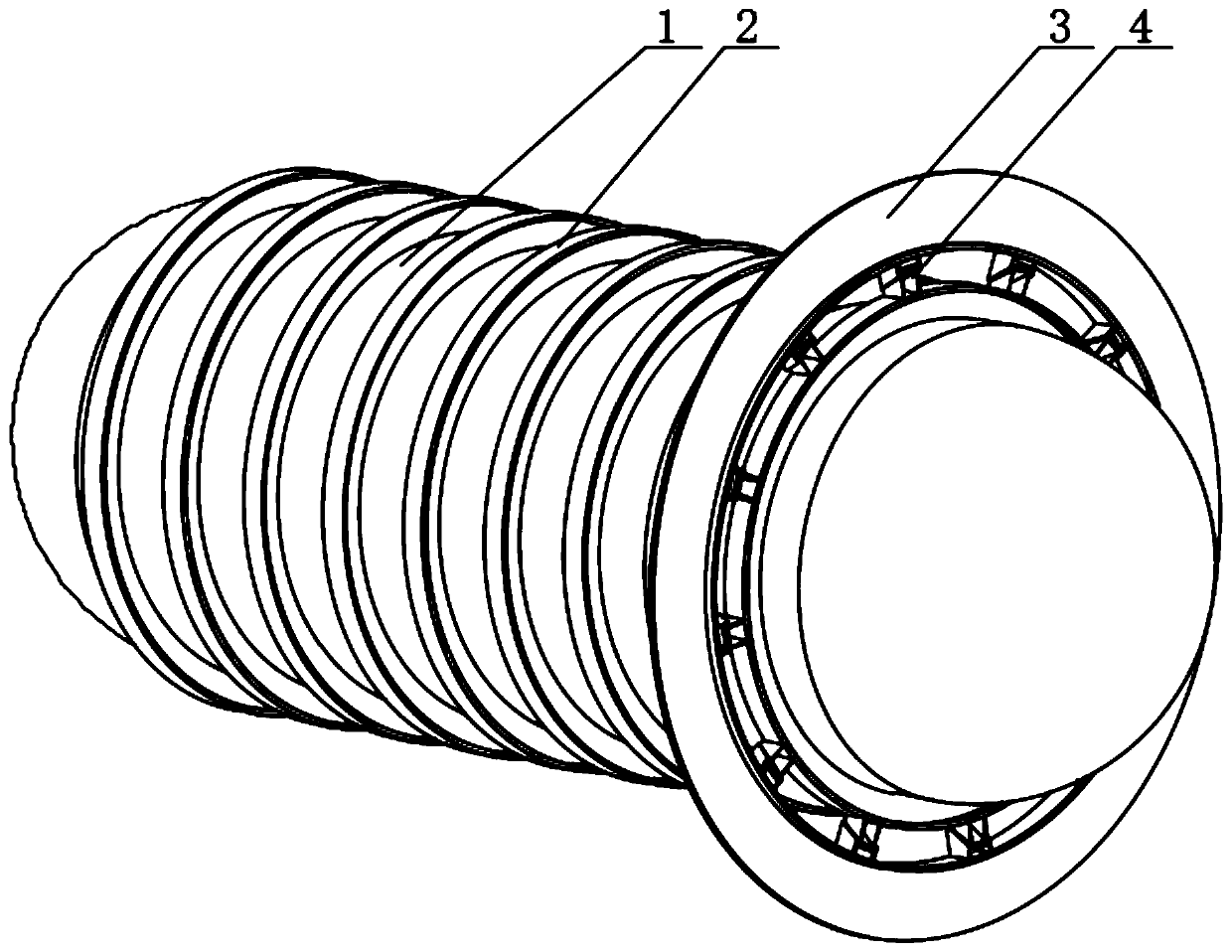

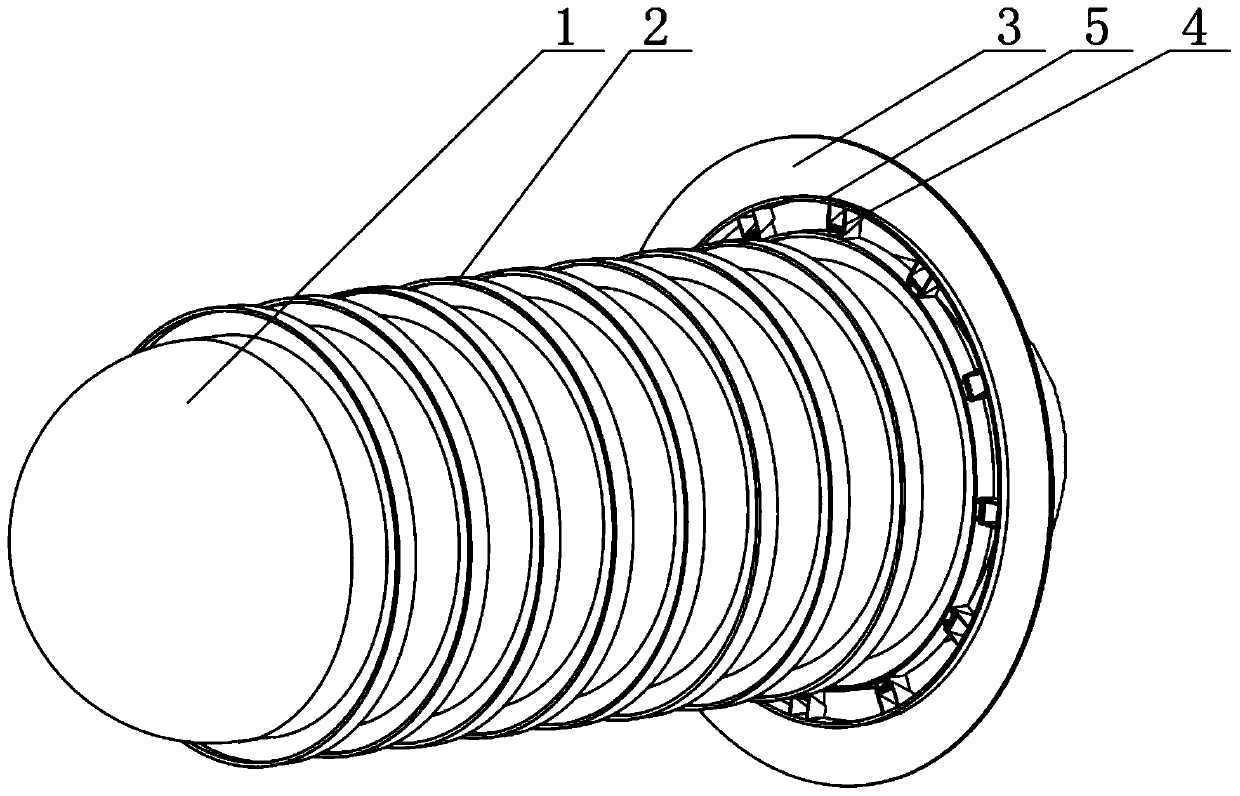

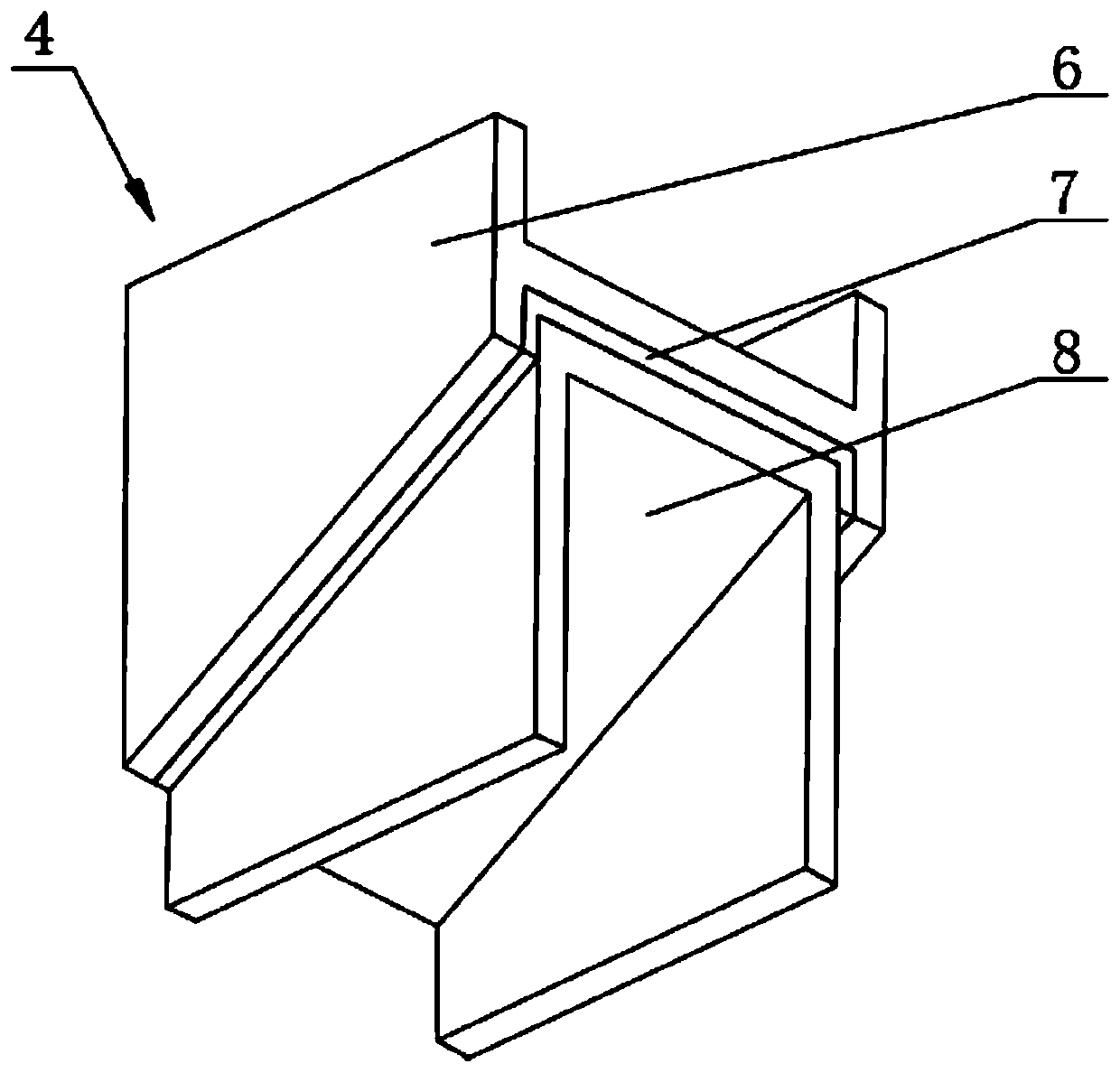

[0044] Such as Figure 1-Figure 6 As shown, the deep-sea submersible pressure body limiting and shrinkage deformation compensating device of the present embodiment includes a pressure body 1, and outer rib panels 2 are arranged in parallel on the outer circumference of the pressure body 1 at intervals, and one of the outer rib panels The panel 2 is nested with non-pressure-resistant structures 3 at intervals, and the bottom of the non-pressure-resistant structure 3 is extended with an inner panel 5 perpendicular to it. The inner panel 5 is arranged in parallel with the outer rib panel 2 at intervals. A plurality of compensation devices 4 are welded between them, and the plurality of compensation devices 4 are evenly spaced and distributed in the circumferential space between the inner panel 5 and the outer rib panel 2 .

[0045] The struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com