A kind of low temperature co-fired ceramic dielectric material and preparation method thereof

A technology of dielectric material and total mass, applied in the field of LTCC dielectric material with adjustable dielectric constant and its preparation, low temperature co-fired ceramic dielectric material and its preparation, can solve the problem of reducing the sintering temperature of LTCC dielectric material, and achieve large Practical value, adjustable dielectric constant, comprehensive material properties and sintering characteristics are easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

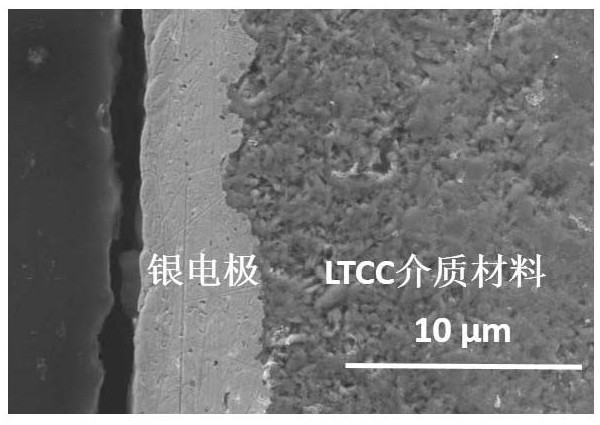

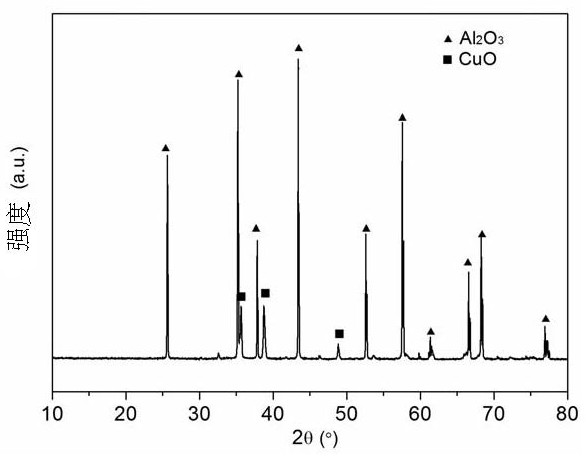

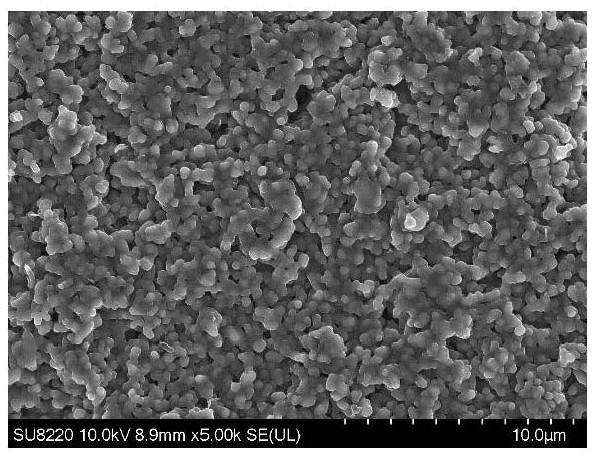

Embodiment 1

[0039] M=Al, A=Cu, B=Nb, x=90wt%, y=10wt%, a=45wt%, b=55wt%, then the LTCC dielectric material xMO m +y(aAO n -bBO t ) can be expressed as 90wt% Al 2 O 3 -10wt%(45wt%CuO-55wt%Nb 2 O 5 ), referred to as CN. with Al 2 O 3 , CuO and Nb 2 O 5 As raw materials, mix the ingredients according to the above proportions and put them into a nylon ball mill tank, add absolute ethanol and grinding balls, and perform ball milling at 300 rpm for 24 hours to mix the raw materials evenly to obtain mixed powder. After drying the mixed powder (holding at 100° C. for 4 hours), molding (pressing at 100 MPa for 1 minute) to obtain a green cylindrical sample. The obtained cylindrical sample green body was sintered at 900° C. for 4 hours to obtain a sintered and dense LTCC dielectric material. X-ray diffraction (XRD pattern, figure 1 ) analysis shows that the ceramic phase composition of the LTCC dielectric material is mainly Al 2 O 3 , no glass phase. The microwave dielectric performa...

Embodiment 2

[0041] M=MgTi, A=Mn, B=Ti, x=85wt%, y=15wt%, a=60wt%, b=40wt%, then the LTCC dielectric material xMO m +y(aAO n -bBO t ) can be expressed as 85wt% MgTiO 3 -15wt% (50wt% MnO 2 -50wt% TiO 2 ), oxide activator is referred to as MT. As synthesized MgTiO 3 , and MnO 2 and TiO 2 As raw materials, mix the ingredients according to the above proportions and put them into a nylon ball mill tank, add absolute ethanol and grinding balls, and carry out ball milling for 24 hours to make the raw materials evenly mixed. After the mixed raw materials are dried, a cylindrical sample green body is obtained after molding, and sintered at 925° C. for 4 hours to obtain a sintered and dense ceramic sample. The microwave dielectric performance test shows that the obtained ceramic sample has a dielectric constant of 18 (@10GHz) and a quality factor of Q·f~22000GHz, showing excellent microwave dielectric performance.

Embodiment 3

[0043] M=NdAl, A=Cu, B=Ti, x=80wt%, y=20wt%, a=50wt%, b=50wt%, then the LTCC dielectric material xMO m +y(aAO n -bBO t ) can be expressed as 80wt% NdAlO 3 -20wt%(50wt%CuO-50wt%TiO 2 ), the oxide activator is referred to as CT. The synthesized NdAlO 3 , and CuO and TiO 2 As raw materials, mix the ingredients according to the above proportions and put them into a nylon ball mill tank, add absolute ethanol and grinding balls, and carry out ball milling for 24 hours to make the raw materials evenly mixed. After the mixed raw materials are dried, a cylindrical sample green body is obtained after molding, and sintered at 925° C. for 4 hours to obtain a sintered and dense ceramic sample. The surface of the microwave dielectric property test shows that the obtained ceramic sample has a dielectric constant of 22 (@10GHz) and a quality factor of Q·f~12000GHz, showing excellent microwave dielectric properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| quality factor | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com