Low-temperature sintered microwave dielectric material and preparation method thereof

A microwave dielectric material and low-temperature sintering technology are applied in the field of low-temperature sintering microwave dielectric materials and their preparation, the composition of low-temperature sintering microwave dielectric materials and their preparation fields, and can solve the problems of unsatisfactory stability, chemical reaction raw materials, special sintering process, etc. Achieve the effect of adjustable dielectric constant, simple preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

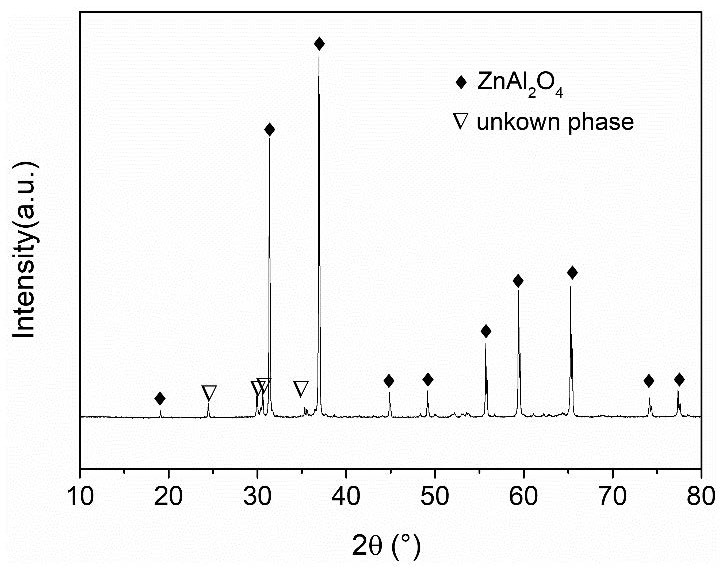

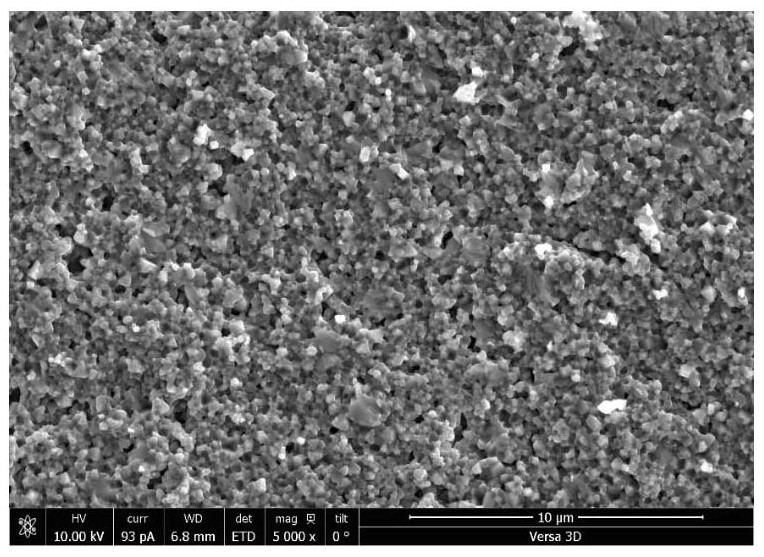

[0044] Select M=Zn, u=1, v=2, w=4, x=90wt%, y=10wt%, a=4(44.4%), b=1(11.2%), c=4(44.4%) . The composition of LTCC dielectric material can be expressed as 90wt% ZnAl 2 o 4 +10wt% (4CuO-TiO 2 -4NbO 2.5 ). Start with Al 2 o 3 Powder and ZnO powder are used as raw materials, mixed by ball milling at a molar ratio of 1:1, and the dried mixture is sintered at 1150°C for 4 hours to obtain the matrix material ZnAl 2 o 4 Powder. ZnAl 2 o 4 Powder, CuO powder, TiO 2 Powder and Nb 2 o 5 The powder is used as the raw material, and the ingredients are mixed according to the above ratio and put into a nylon ball mill jar, adding absolute ethanol and balls, and ball milling for 12 hours to make the raw materials evenly mixed. Dry the mixed raw materials and perform molding treatment to obtain a cylindrical green body, which is sintered at 950° C. for 4 hours to obtain a sintered dense ceramic sample. X-ray diffraction (XRD) analysis shows that the phase composition of ceramics...

Embodiment 2

[0046] Select M=Zn, u=1, v=2, w=4, x=95wt%, y=5wt%, a=4(44.4%), b=1(11.2%), c=4(44.4%) . The composition of LTCC dielectric material can be expressed as 95wt% ZnAl 2 o 4 +5wt% (4CuO-TiO 2 -4NbO 2.5 ). Start with Al 2 o 3 Powder and ZnO powder are used as raw materials, mixed by ball milling at a molar ratio of 1:1, and the dried mixture is sintered at 1150°C for 4 hours to obtain the matrix material ZnAl 2 o 4 Powder. ZnAl 2 o 4 Powder, CuO powder, TiO 2 Powder and Nb2O 5 The powder is used as the raw material, and the ingredients are mixed according to the above ratio and put into a nylon ball mill jar, adding absolute ethanol and balls, and ball milling for 12 hours to make the raw materials evenly mixed. Dry the mixed raw materials and perform molding treatment to obtain a cylindrical green body, which is sintered at 1050° C. for 4 hours to obtain a sintered dense ceramic sample. X-ray diffraction (XRD) analysis shows that the phase composition of ceramics is ...

Embodiment 3

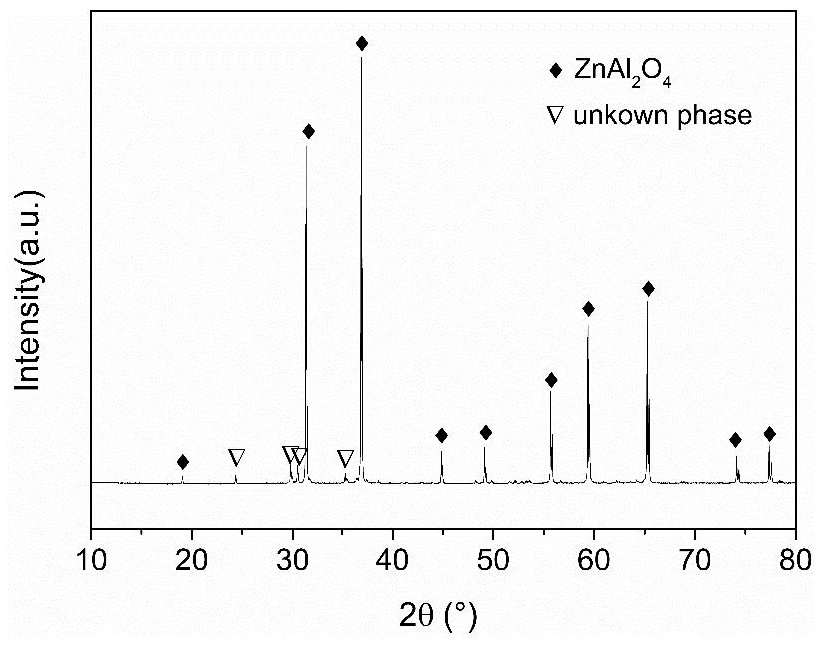

[0048] Choose M=Zn, u=1, v=2, w=4, x=95wt%, y=5wt%, a=1(50%), b=0, c=1(50%). The composition of LTCC dielectric material can be expressed as 95wt% ZnAl 2 o 4 +5wt% (CuO-NbO 2.5 ). Start with Al 2 o 3 Powder and ZnO powder are used as raw materials, mixed by ball milling at a molar ratio of 1:1, and the dried mixture is sintered at 1150°C for 4 hours to obtain the matrix material ZnAl 2 o 4 Powder. ZnAl 2 o 4 powder, CuO powder and Nb 2 o 5 The powder is used as the raw material, and the ingredients are mixed according to the above ratio and put into a nylon ball mill jar, adding absolute ethanol and balls, and ball milling for 12 hours to make the raw materials evenly mixed. Dry the mixed raw materials and perform molding treatment to obtain a cylindrical green body, which is sintered at 975° C. for 4 hours to obtain a sintered dense ceramic sample. X-ray diffraction (XRD) analysis shows that the phase composition of ceramics is mainly ZnAl 2 o 4 , XRD pattern se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com