Distillation pot for baijiu production and with functions of multi-directional flat blowing and falling prevention

A multi-directional, stilling pot technology, applied in the field of stilling pots, can solve the problems of reducing the distillation rate, affecting the wine rate, and the inability of materials to achieve the effect of increasing the range of blowing, avoiding bridging, and increasing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

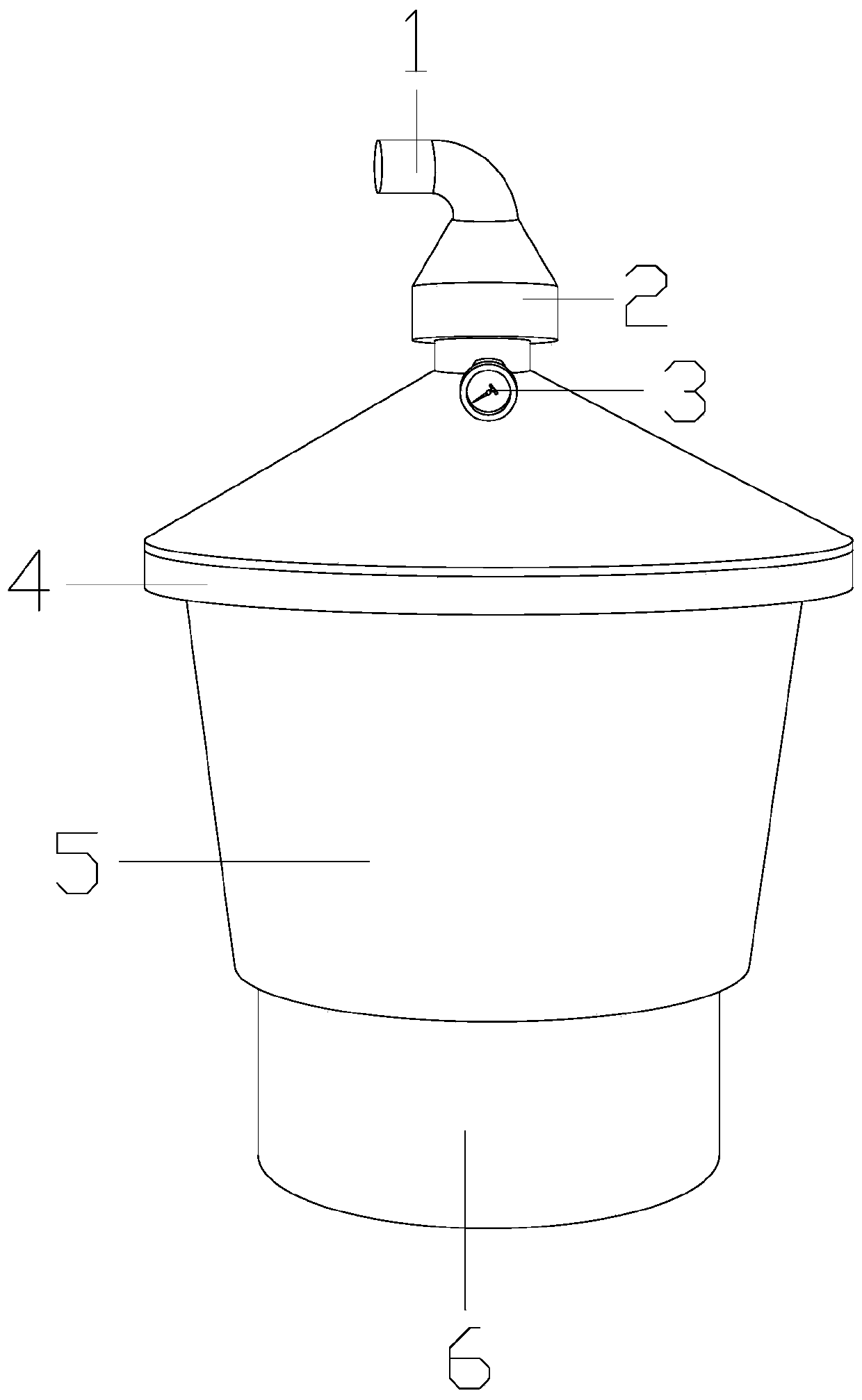

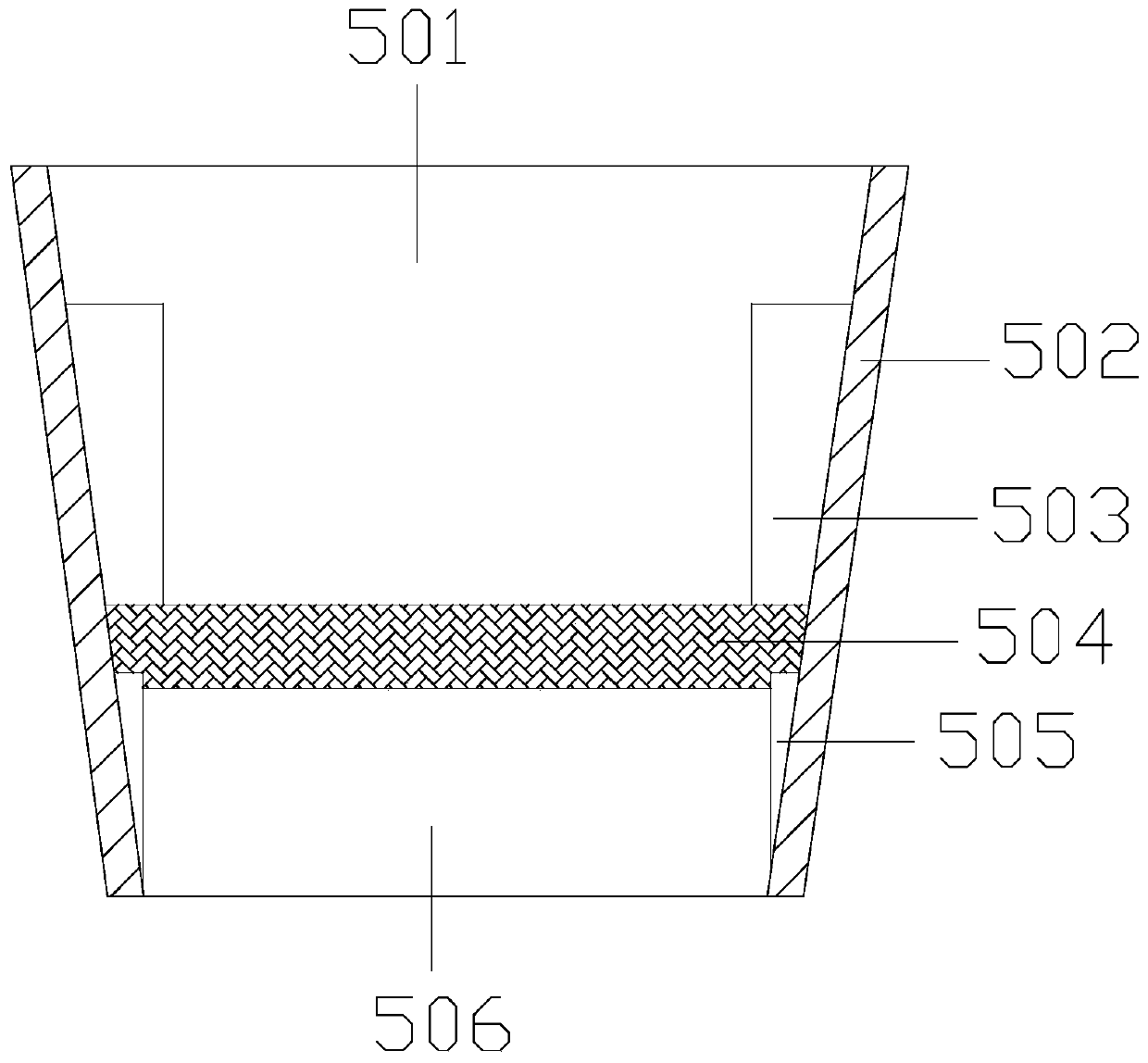

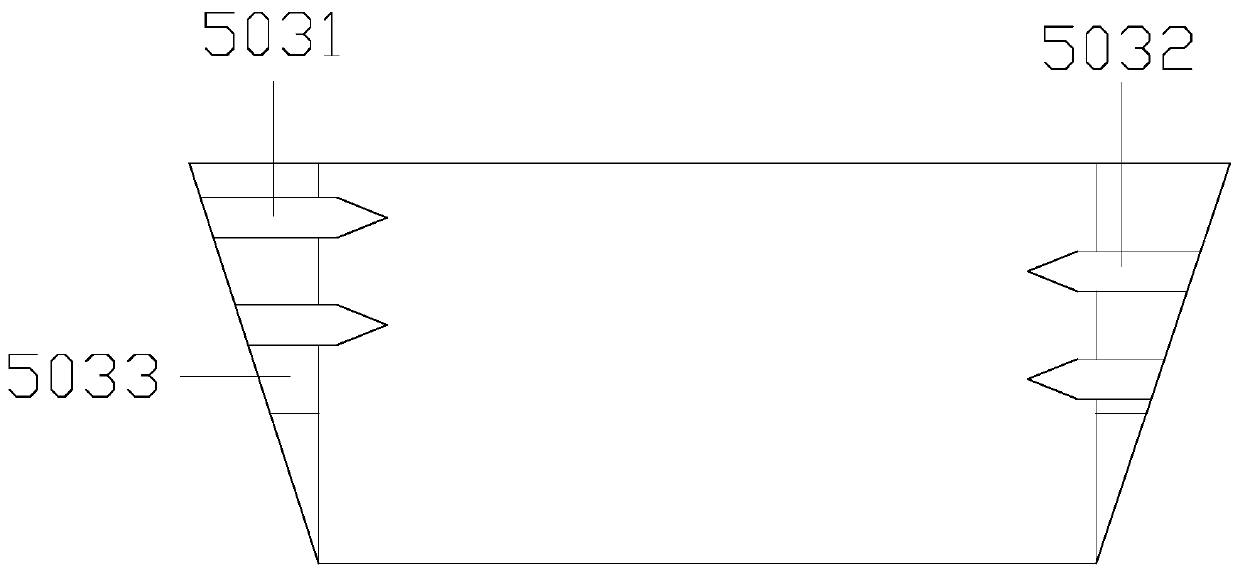

[0023] see Figure 1-Figure 6 , the present invention provides a multi-directional flat-blown and anti-drop distillation pot for liquor production: its structure includes: a steam outlet pipe 1, a connector 2, a pressure gauge 3, an upper cover 4, a distillation barrel 5, and an evaporator 6. The lower end of the steam outlet pipe 1 is connected to and communicated with the upper end of the connector 2, the lower end of the connector 2 is nested with a pressure gauge 3, and the lower surface of the upper cover 4 is connected to the upper surface of the distillation barrel 5. Fitting and fastening, an evaporator 6 is provided under the distillation barrel 5, and the distillation barrel 5 includes a material chamber 501, a casing 502, and a propelle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com