a pump set

A pump set and centrifugal pump technology, applied in waterway systems, cleaning methods using liquids, cleaning sewer pipes, etc., can solve problems such as impurity or oil pollution treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

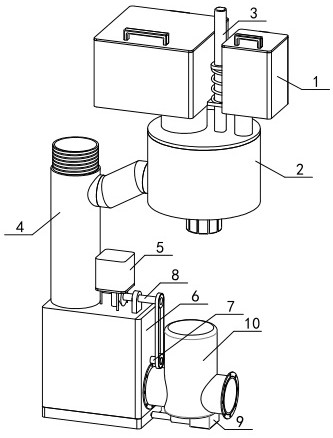

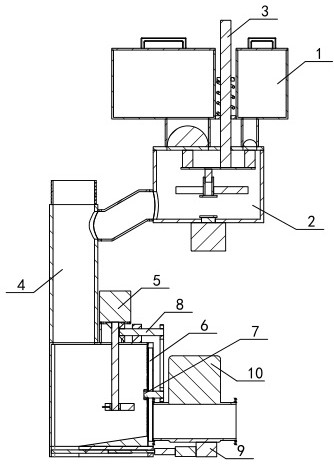

[0034] Such as Figure 1-13 As shown, a pump set includes a reserve tank 1, a preparation tank 2, a trigger mechanism 3, a main pipe 4, a multifunctional device 5, a deflector 6, a matching brush 7, a transmission part 8, a release valve 9 and a vertical centrifugal pump 10. The storage box 1 is fixedly connected to the preparation box 2, the trigger mechanism 3 is connected to the storage box 1, the trigger mechanism 3 is connected to the preparation box 2, the main pipe 4 is fixedly connected to and communicated with the preparation box 2, and the multifunctional device 5 is connected to the main pipe 4 connection, the deflector 6 is fixedly connected with the right end of the main pipe 4, the left end of the deflector 6 is provided with a filter screen, the matching brush 7 is rotationally connected with the deflector 6, the matching brush 7 is in contact with the filter screen, and the multifunctional device 5 is in contact with the transmission part 8 meshing transmission...

specific Embodiment approach 2

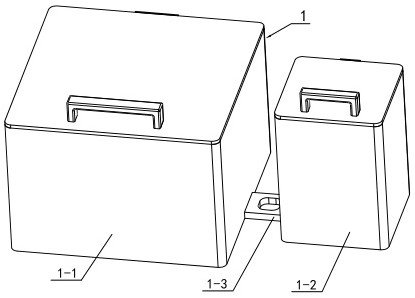

[0036] Such as Figure 1-13 As shown, the storage tank 1 includes a water tank 1-1, an essence tank 1-2 and a connecting block 1-3, and the water tank 1-1 and the essence tank 1-2 are fixedly connected by the connecting block 1-3 , the water tank 1-1 and the essence box 1-2 are all provided with lids. The water tank 1-1 is used to store water, and the essence box 1-2 is used to store cleaning agents, such as pipe cleaners, oil stain cleaners, etc. The lids on the water tank 1-1 and the essence box 1-2 can be hinged at one end, and the other end As the cover of the movable end, the cover directly through the snap-fit can also be used.

specific Embodiment approach 3

[0038] Such as Figure 1-13As shown, the preparation box 2 includes a preparation box body 2-1, a sealing plate 2-2, a connecting pipe 2-3, a flushing pipe 2-4, a motor I2-5 and a friction disc I2-6, and the preparation box The upper end of the body 2-1 is fixedly connected to the sealing plate 2-2, the sealing plate 2-2 is fixedly connected to and communicated with two connecting pipes 2-3, and the flushing pipe 2-4 is fixedly connected to and communicated with the left end of the preparation box body 2-1 The lower side of the motor I2-5 is fixedly connected to the lower end of the preparation box body 2-1, the output shaft of the motor I2-5 is rotationally connected to the lower end of the preparation box body 2-1, and the upper end of the output shaft of the motor I2-5 is fixedly connected to the friction Disk I 2-6; the two connecting pipes 2-3 are fixedly connected and communicated with the lower ends of the water tank 1-1 and the essence tank 1-2 respectively. When the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com