Narrow-period long-wave infrared multi-layer grating structure

A technology of long-wave infrared and grating structure, which is applied in the direction of diffraction grating, optics, optical elements, etc., can solve the problem that the grating area cannot meet the infinite preconditions, and achieve the effect of low sideband effect and good bandpass characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

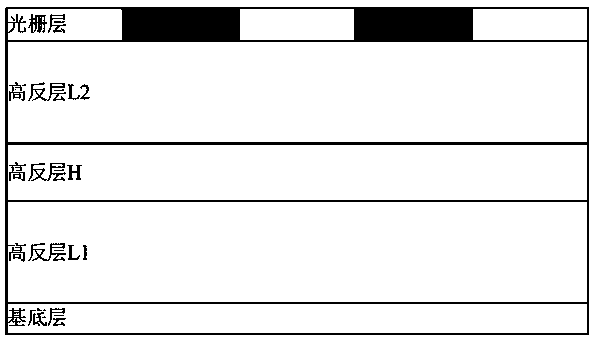

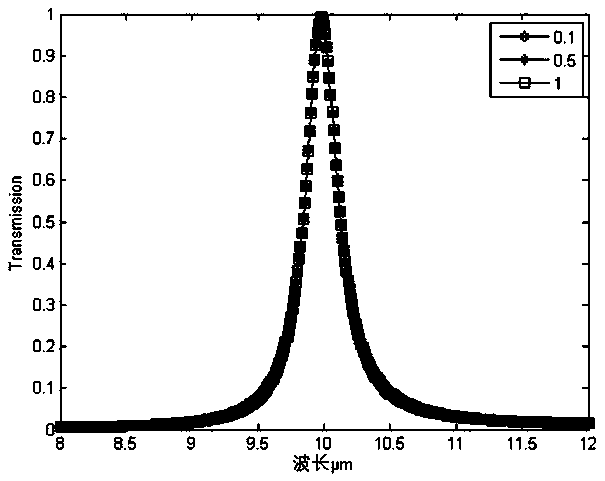

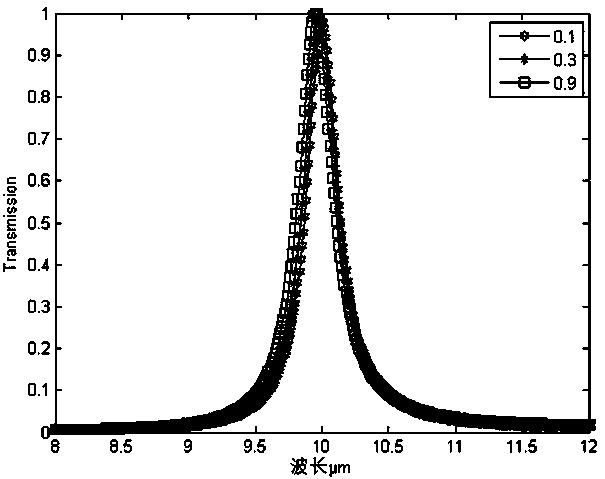

[0030] Such as Figure 1-6 As shown, it shows the specific implementation of the present invention. As shown in the figure, the present invention discloses a narrow-period long-wave infrared multilayer bandpass grating structure whose grating period can be freely adjusted from 0.1 μm to 1 μm, which solves the problem There is a problem that the large-period grating cannot satisfy the precondition of an infinitely large grating area when forming a grating array.

[0031] The present invention adopts the following technical solutions, as shown in the figure: a five-layer grating structure composed of metal and dielectric materials. Typical structure includes: grating layer, base layer and high reflection layer (LHL three layers).

[0032] The beneficial effect of the present invention is that the metal material germanium commonly used in long-wave infrared and the dielectric material tellurium and sodium chloride are used in combination, and a brand-new five-layer grating struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com