Sea cucumber fruity beverage and processing method thereof

A processing method and technology of sea cucumber, applied in the field of comprehensive utilization of seafood, can solve the problems of few deep-processed products, low level of high-value development, and lag in the level of deep-processing technology, and achieve the effect of unique taste and good sensory quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

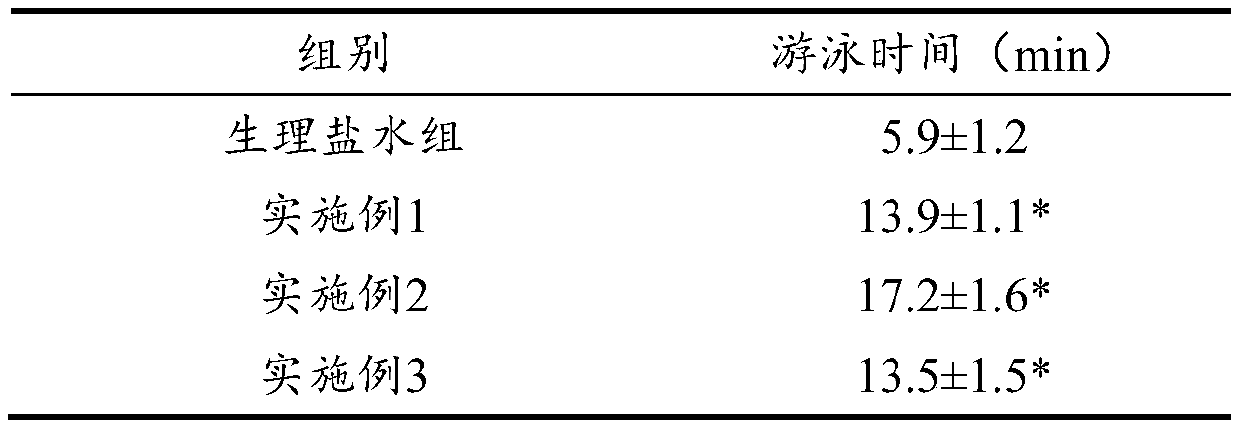

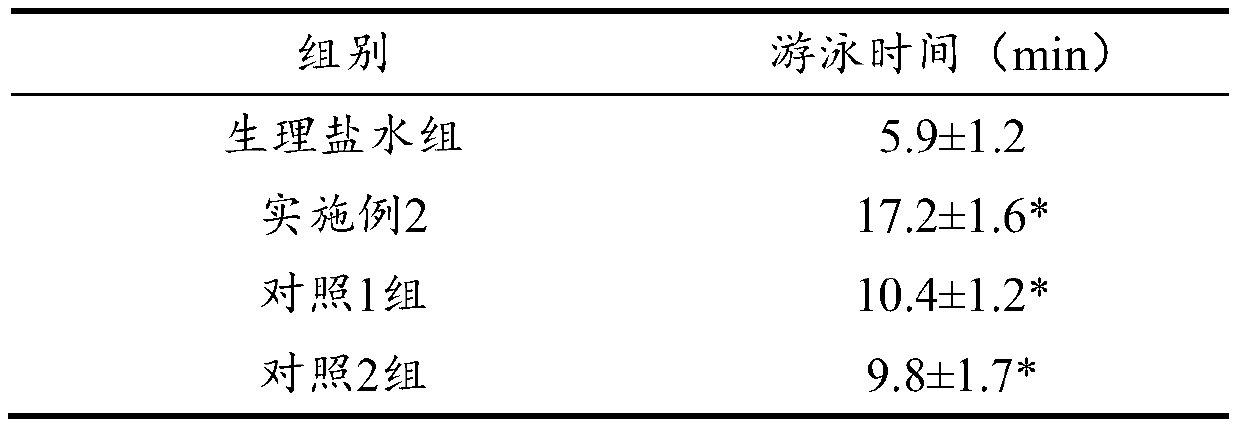

Examples

Embodiment 1

[0039] Clean the fresh sea cucumbers, take them out, add 1 times the amount of water to make a slurry, and mince the sea cucumbers. Heat the sea cucumber slurry at 35°C for 1 hour, use sea cucumber autolyzate to enzymatically hydrolyze, then add flavor protease for enzymolysis, the mass ratio of flavor protease to sea cucumber is 0.01%, the temperature is 45°C, and the pH of enzymolysis is 6.5 , the time is 3h. Continue to add lipase to carry out the enzymolysis of sea cucumber lipids, the amount of lipase added to the mass ratio of sea cucumber is 0.01%, the temperature is 55° C., the enzymolysis pH is 6.5, and the time is 3 hours. Continue to add yeast powder for flavor modification, the amount of yeast powder added to the mass ratio of sea cucumber is 0.1%, the temperature is 35° C., and the time is 2 hours. Centrifuge the enzymolyzate at 3000r / min for 30min. Take the enzymatic hydrolysis supernatant for later use. Squeeze pomegranate juice, break blueberry and mulberry,...

Embodiment 2

[0041]Clean the fresh sea cucumbers, take them out, add 1 times the amount of water to make a slurry, and mince the sea cucumbers. Heat the sea cucumber slurry at 45°C for 2 hours, use sea cucumber autolyzate to enzymatically hydrolyze, then add flavor protease for enzymolysis, the mass ratio of flavor protease to sea cucumber is 0.03%, the temperature is 40°C, and the enzymolysis pH is 7 , the time is 2h. Continue to add lipase to carry out the enzymolysis of sea cucumber lipids, the amount of lipase added to the mass ratio of sea cucumber is 0.02%, the temperature is 45° C., the enzymolysis pH is 7, and the time is 2 hours. Continue to add yeast powder for flavor modification, the amount of yeast powder added is 0.2% of the mass ratio of sea cucumber, the temperature is 45° C., and the time is 4 hours. Centrifuge the enzymolyzate at 5000r / min for 20min. Take the enzymatic hydrolysis supernatant for later use. Squeeze pomegranate juice, break blueberry and mulberry, and mi...

Embodiment 3

[0043] Clean the fresh sea cucumbers, take them out, add 1 times the amount of water to make a slurry, and mince the sea cucumbers. Incubate the sea cucumber slurry at 55°C for 1 hour, use sea cucumber autolytic enzyme to carry out enzymatic hydrolysis, then add flavor protease for enzymolysis, the mass ratio of flavor protease to sea cucumber is 0.05%, the temperature is 55°C, and the enzymolysis pH is 7.5 , the time is 1h. Continue to add lipase to carry out the enzymolysis of sea cucumber lipids, the amount of lipase added to the mass ratio of sea cucumber is 0.05%, the temperature is 55° C., the enzymolysis pH is 7.5, and the time is 1 h. Continue to add yeast powder for flavor modification, the weight ratio of yeast powder to sea cucumber is 0.3%, the temperature is 55° C., and the time is 2 hours. The enzymolysis solution was centrifuged at 6000 r / min for 15 minutes. Take the enzymatic hydrolysis supernatant for later use. Squeeze pomegranate juice, break blueberry an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com