Crankshaft milling machining center

A machining center and crankshaft technology, applied in metal processing equipment, metal processing machinery parts, milling machines, etc., can solve the problems of increased crankshaft position angle and eccentricity error, poor crankshaft machining accuracy, low crankshaft machining efficiency, etc., to achieve Effects of reducing unbalance, improving processing quality, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further explained below in conjunction with the accompanying drawings.

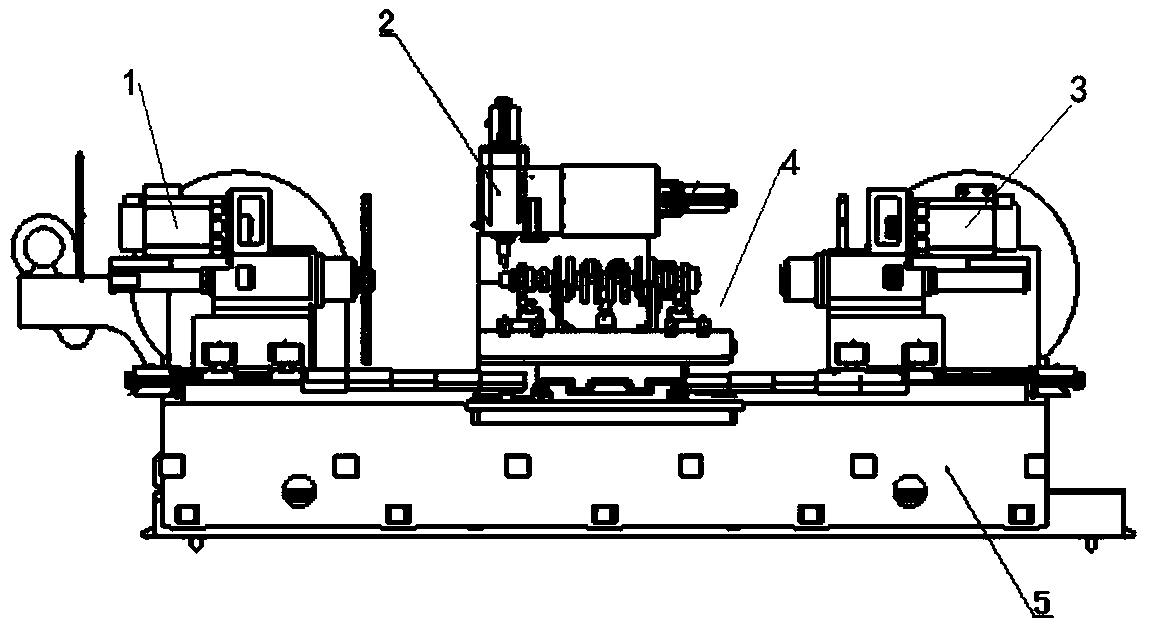

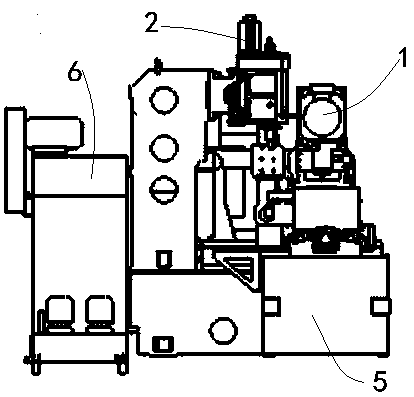

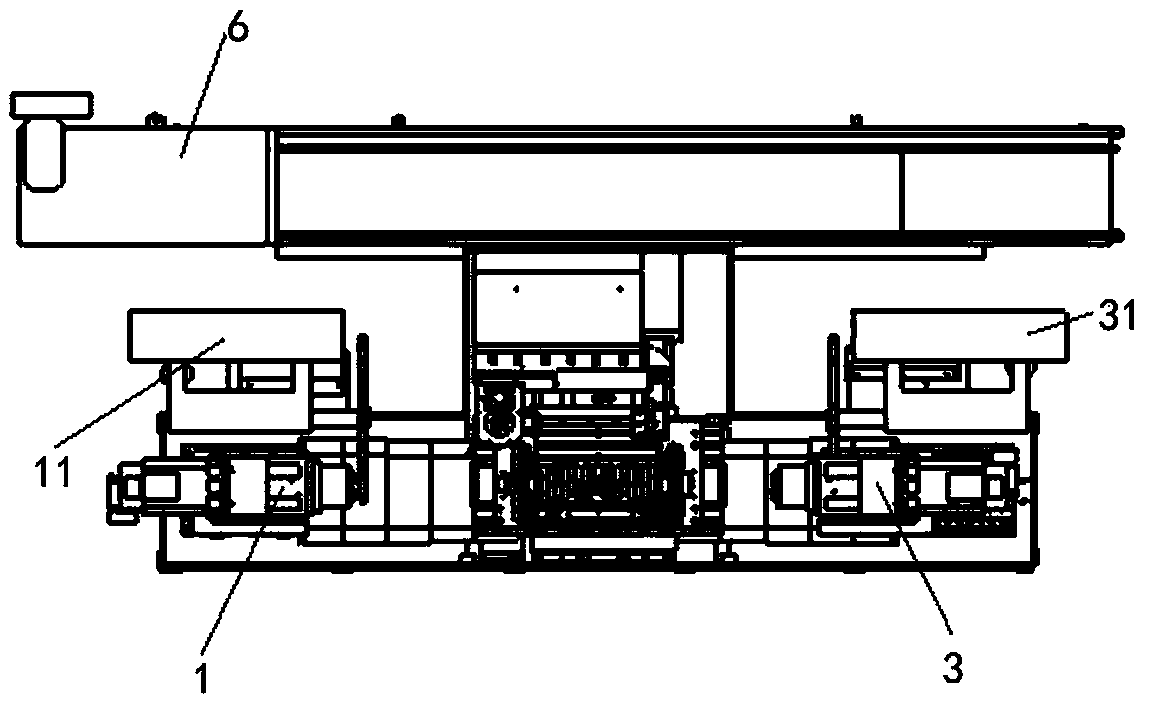

[0026] A crankshaft milling machining center, comprising a left main shaft 1, an end milling shaft 2, a right main shaft 3 and a clamping device 4 for clamping a crankshaft 10, the workbench 41 of the clamping device 4 is provided with two left and right A centering clamping mechanism 7, an angular positioning mechanism 8, an axial positioning mechanism 9 and two brackets 42; the centering clamping mechanism 7 is slidable in the crankshaft 10 axial direction, and the angular positioning mechanism 8 is The crankshaft 10 is slidable in the radial direction, and the axial positioning mechanism 9 is arranged on the workbench 41 in the area between the two centering clamping mechanisms 7 .

[0027] In the crankshaft milling and machining center described above, the centering clamping mechanism 7 includes a V-shaped claw 71 for clamping and cooperating with the shaft diamete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com